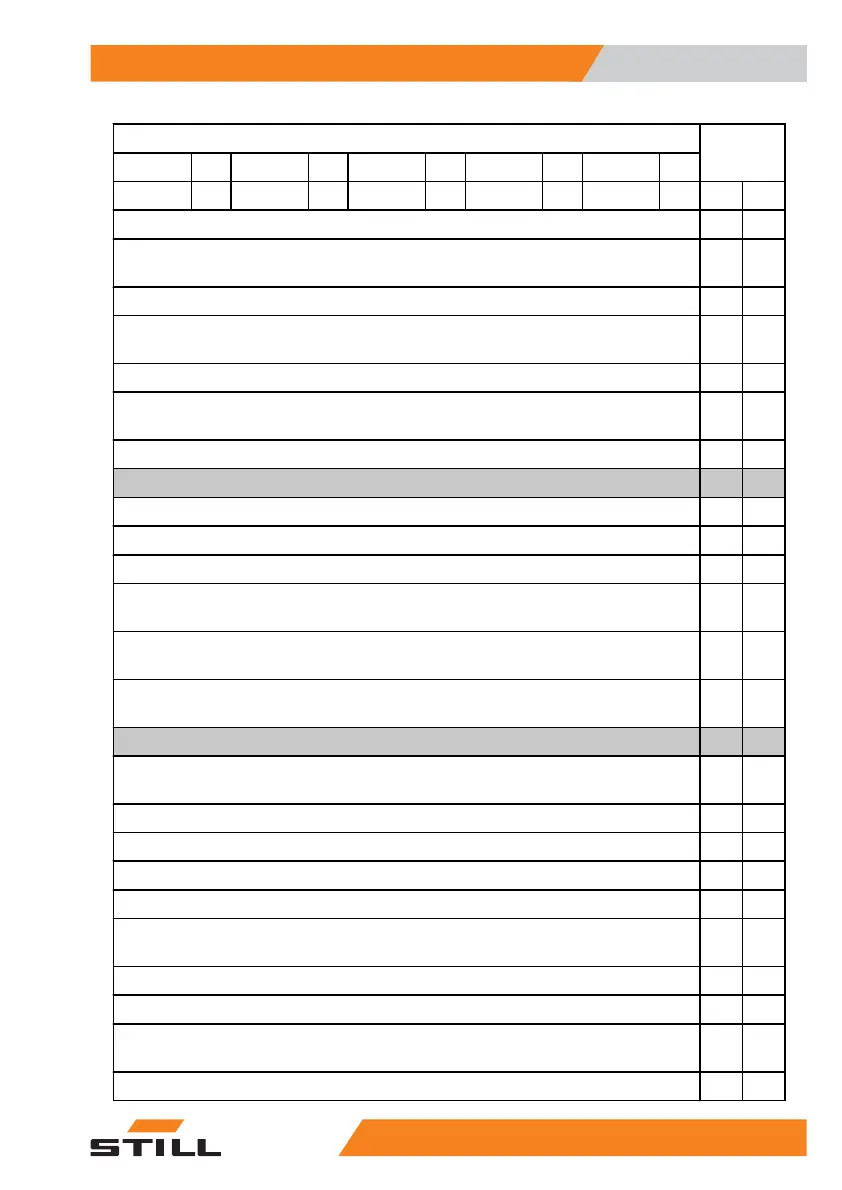

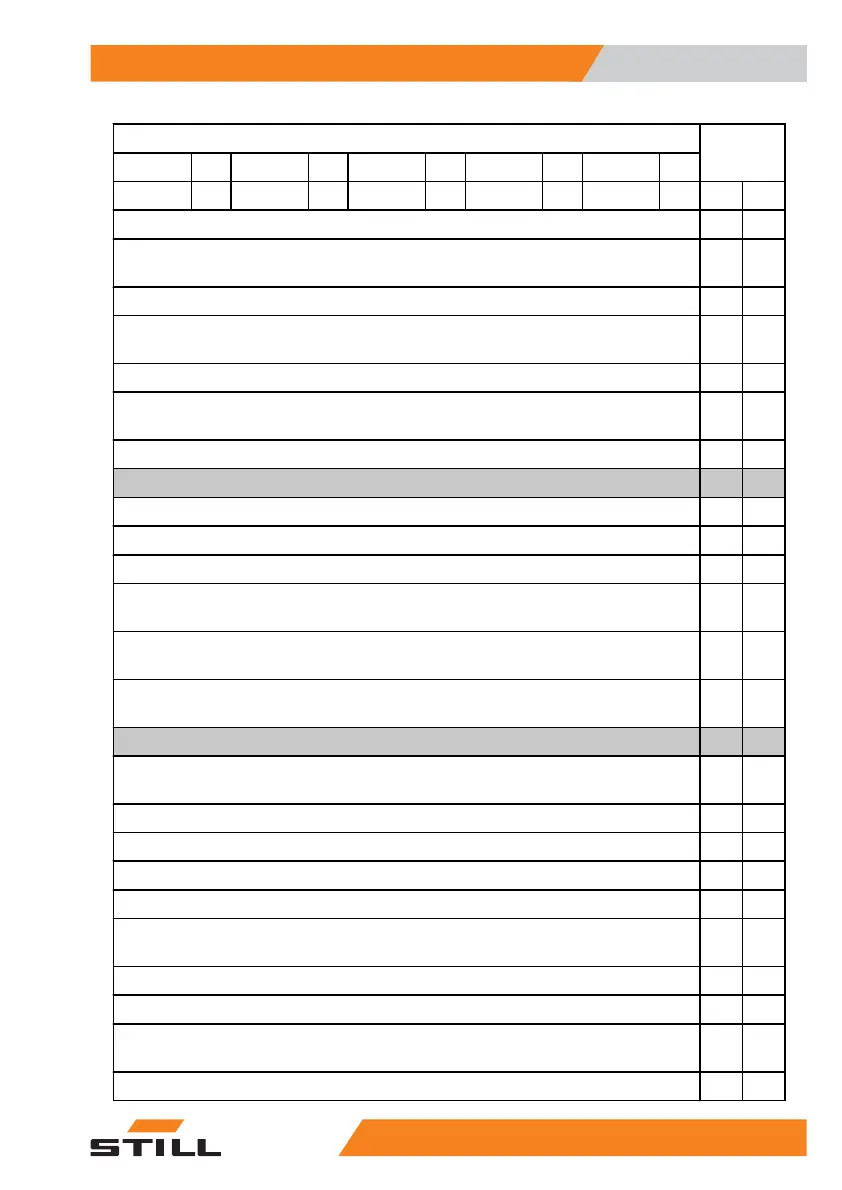

At operating hours

1000 h

2000 h

3000 h

4000 h

5000 h

6000 h

7000 h

8000 h

9000 h

10000 h

Carried

out

Load wheels: check the brake clearance by freewheeling.

Load wheels: check the condition and thickness of the brake lining. Replace if nec-

essary.

Brake lining: blow out abrasion with oil-free air.

Brake retardation values: check after each adjustment (dynometer or retardation

measuring device).

Automatic braking: check the function as per the order.

Components for automatic braking (inductive switch/photoswitch/magnet-operated

switch): check the function, setting and condition.

Components of the RFID system: check the function, condition and setting.

Operating devices

Check that the service brake is working correctly.

Operating devices: check the function and condition.

Protective devices: check depending on the equipment. Repair if necessary.

Information signs, warning signs, load capacity diagram: check that they are present

and legible.

Information signs, warning signs, load capacity diagram: replace missing or illegible

labels.

Optional and additional equipment: check the function and condition according to

the order.

Electrics, electronics

Battery cables, battery connectors, battery male connectors: check the condition

and check for secure attachment.

Battery cables: visually check the insulation.

Battery: measure the battery voltage under load

Battery: measure the tray for short circuits.

Battery: check the electrolyte level.

Drive and pump controller: check the driving, acceleration, braking and reversing

functions.

Plugs and connections: check that they are securely attached.

Openly routed cables: visually inspect the insulation.

Contactor contacts: check the condition and check for erosion. Replace if necessa-

ry.

Visually check the condition of the fuses.

Regular care and maintenance

5

1000-hour maintenance schedule

1015231 804 2502 EN - 04/2020

Loading...

Loading...