Setting the battery lock

CAUTION

Risk of crushing and damage to property

An improperly fixed battery may fall out of the truck

when cornering and put people and property at risk.

If the battery cannot be clamped securely, the re-

sponsible service centre must be called. Further op-

eration with a faultily or improperly clamped battery is

dangerous.

To ensure the operational safety of this truck,

the traction battery must be securely fixed in

place in the battery compartment by means of

clamps. To achieve this, the truck is equipped

with an adjustable battery lock. The battery

lock can be adjusted by approx. 30 mm on

each side. Both locks must be adjusted sym-

metrically.

NOTE

When a battery is inserted into a chassis for

the first time, it is possible that the actions de-

scribed below may need to be repeated in

several steps. If the rubber buffer thread

(spring element) is not able to move smoothly,

this must be rectified before setting.

– Insert the battery approximately in the cen-

tre of the battery compartment. In doing so,

one of the battery locks will remain as a

stop in the truck.

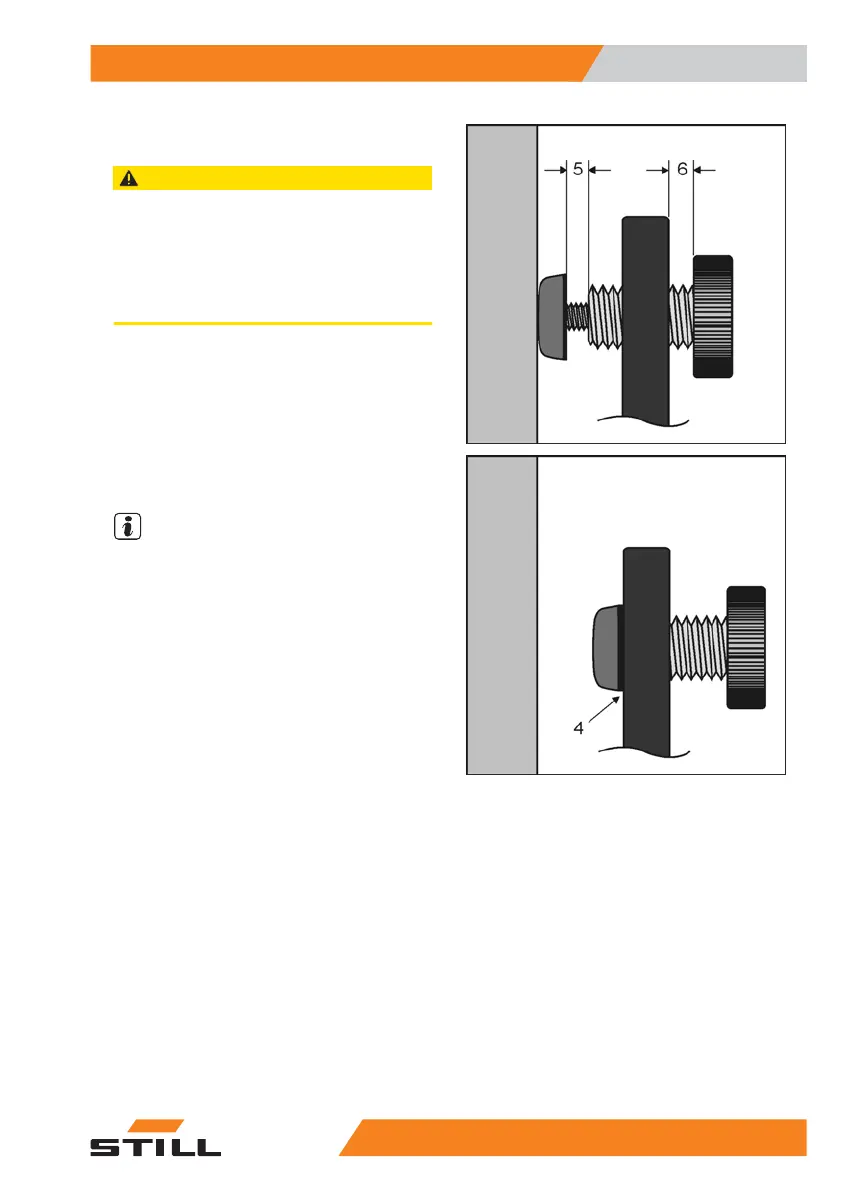

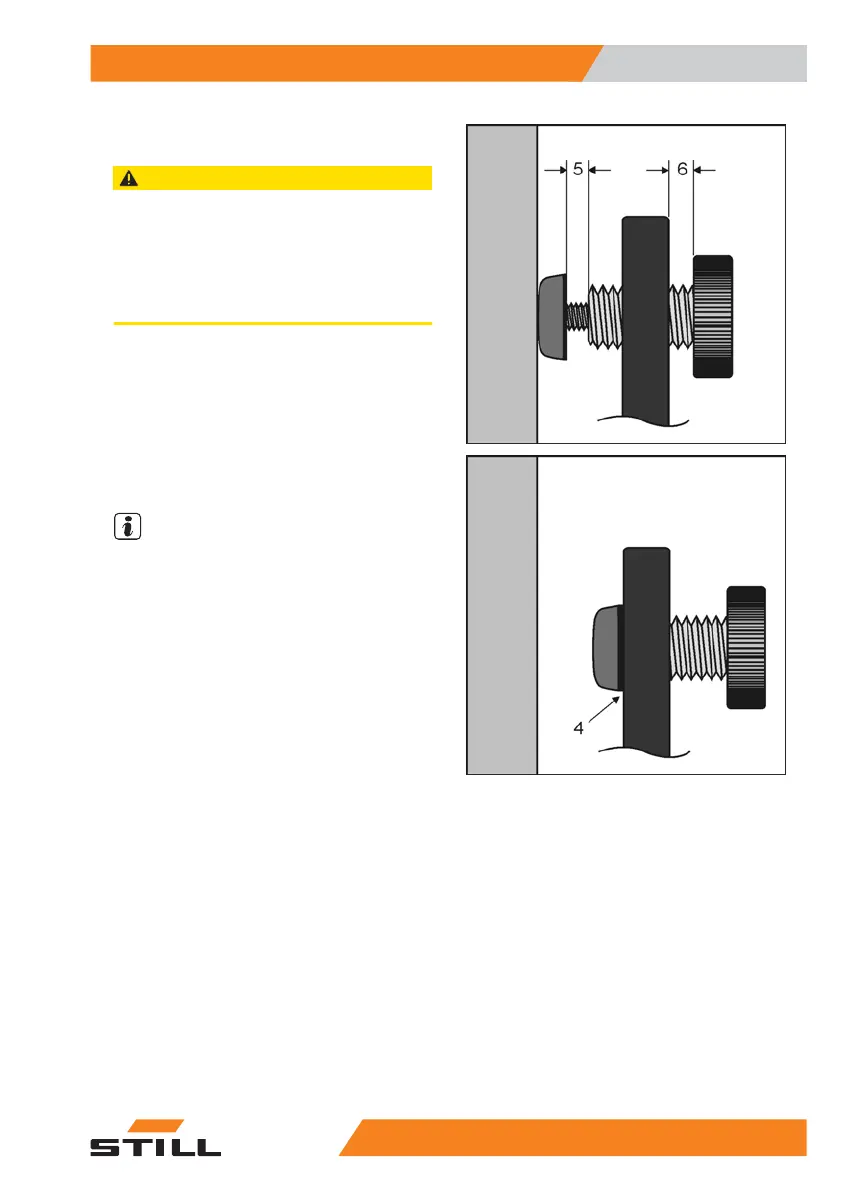

– Rotate the knurled-head screw (1) and the

rubber buffer (3) all the way back (4) on

both locks (2).

– Insert the second battery lock into the truck.

– Unscrew both rubber buffers until they lie

against the battery. The visible thread

length should be roughly the same on both

sides of the battery. Gently move the bat-

tery to the side, if necessary The maximum

adjustment range for each rubber buffer is

approximately 20 mm.

– If the useable threads on both rubber buf-

fers are not long enough to fasten the buf-

fers to the battery, the knurled-head screws

must be screwed in to further increase the

adjustment range. At the same time, the

Special equipment

7

Battery on a roller channel

1235231 804 2502 EN - 04/2020

Loading...

Loading...