The information contained in this document is confidential, and only for the information of the intended recipient and may not be published or redistributed without the prior written consent of Summa NV.

Summa nv Tel +32 59 27 00 11 Fax +32 59 27 00 63 Email support@summa.com Website www.summa.com Page 40 of 76

• In case the machine is equipped with a drag knife cutter head, then check the position of the

drag knife holder in the tool clamp of the cutter head. Make sure the rear position is used to

cut over the cutting strip.

• The floor may not be level. Because of this there may be torsion on the machine causing

cutting depth to change over the width of the machine.

• The cutting strip may be worn and needs replacement (reference 400-565).

• The bearings in the cutter head may be worn. Due to this, the knife cannot move smooth up

and down, causing irregular cutting depth. Replace the cutter head.

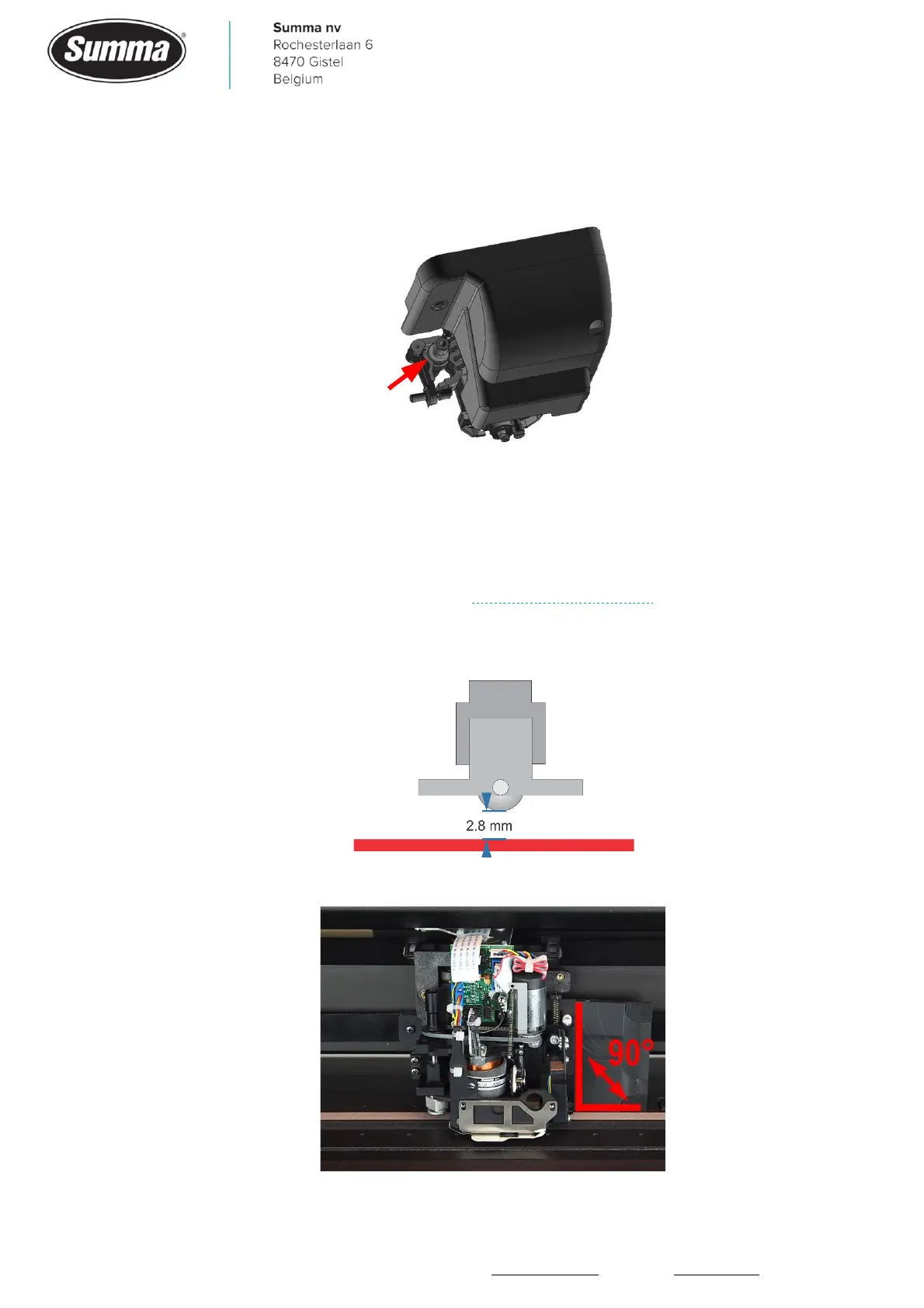

• The cutter head may have been mounted too high. Spacing between the rollers of the white

nose piece and the cutting strip should be 2.8 mm (+/- 0.2 mm).

• The cutter head may not have been mounted perpendicular on the cutter head carriage.

Loading...

Loading...