The information contained in this document is confidential, and only for the information of the intended recipient and may not be published or redistributed without the prior written consent of Summa NV.

Summa nv Tel +32 59 27 00 11 Fax +32 59 27 00 63 Email support@summa.com Website www.summa.com Page 32 of 76

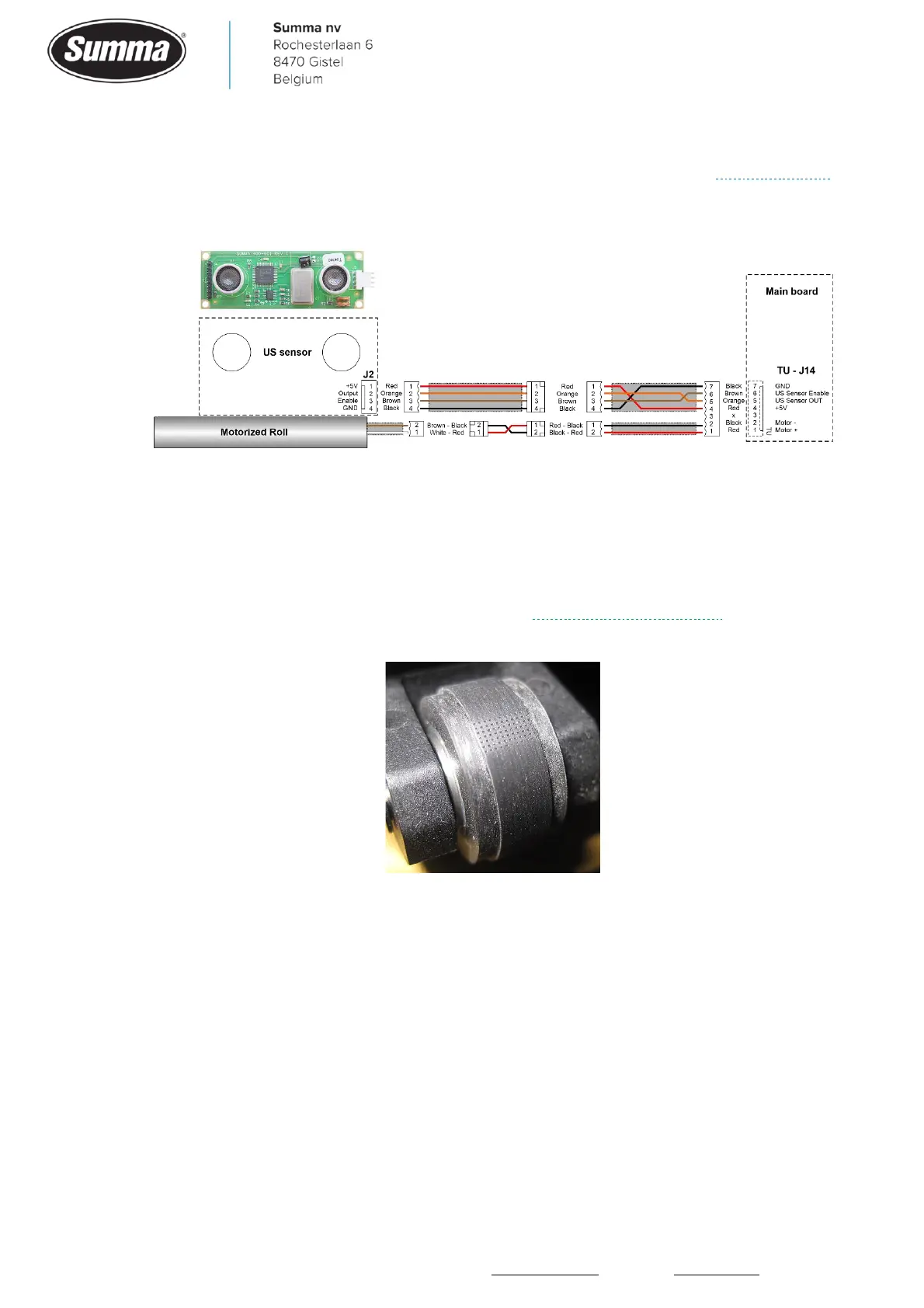

• The wiring may be incorrect. Check the wiring between the main board and the ultrasonic

sensor in case the status of the ultrasonic sensor does not change in the monitor screen.

Check the wiring between the main board and the motorized roll in case the roll does not

rotate, or rotates in the wrong direction.

4.21 Ticking sound

When the machine produces a ticking sound when the media is transported, then check the

following:

• Pinch rollers were for long time lowered on the media when the machine was inactive. This

may have created a flat surface on the pinch roller. Replace the pinch rollers. Lift the pinch

rollers when the machine stands idle for more than 2 hours.

• Glue may stick on the pinch rollers. Clean the pinch rollers with a cloth and isopropyl-alcohol.

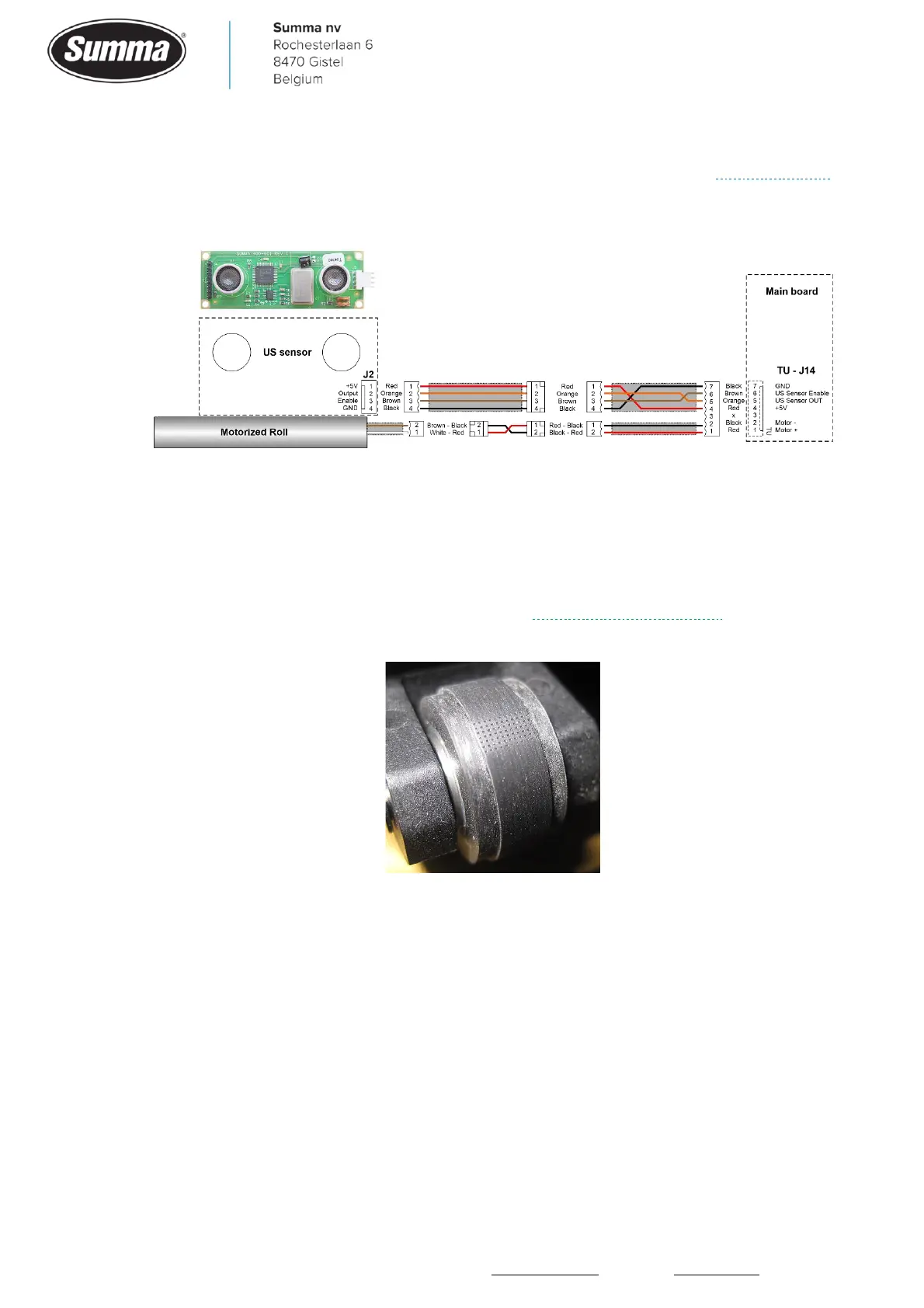

• The drive drum may have collected glue from the media. Clean the drive drum.

• The bearings used to support the drive drum may have become dirty. Clean with compressed

air.

• One of the bearings used to support the drive drum may have clogged grease. Spray WD40 in

the bearings.

Loading...

Loading...