The information contained in this document is confidential, and only for the information of the intended recipient and may not be published or redistributed without the prior written consent of Summa NV.

Summa nv Tel +32 59 27 00 11 Fax +32 59 27 00 63 Email support@summa.com Website www.summa.com Page 13 of 76

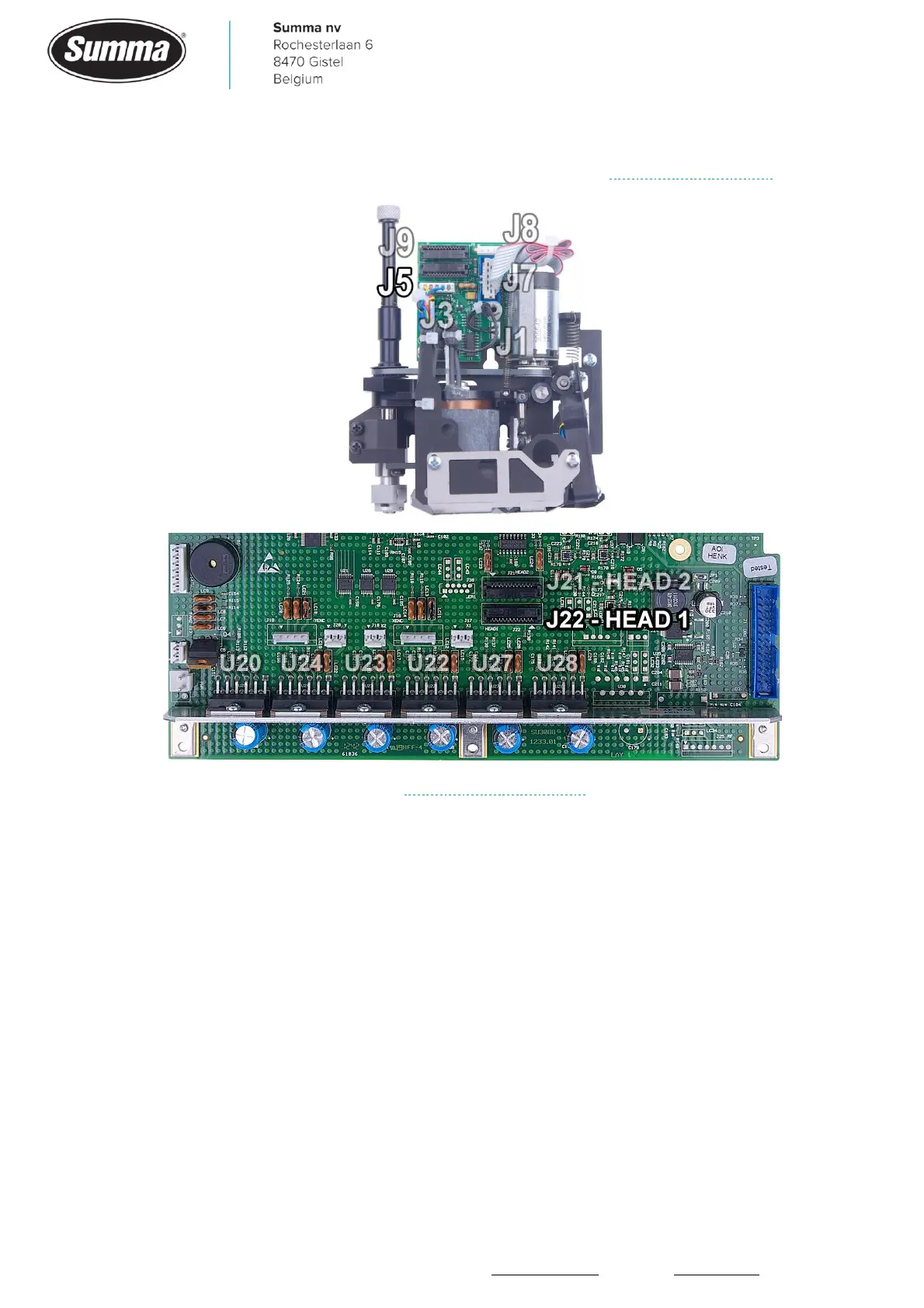

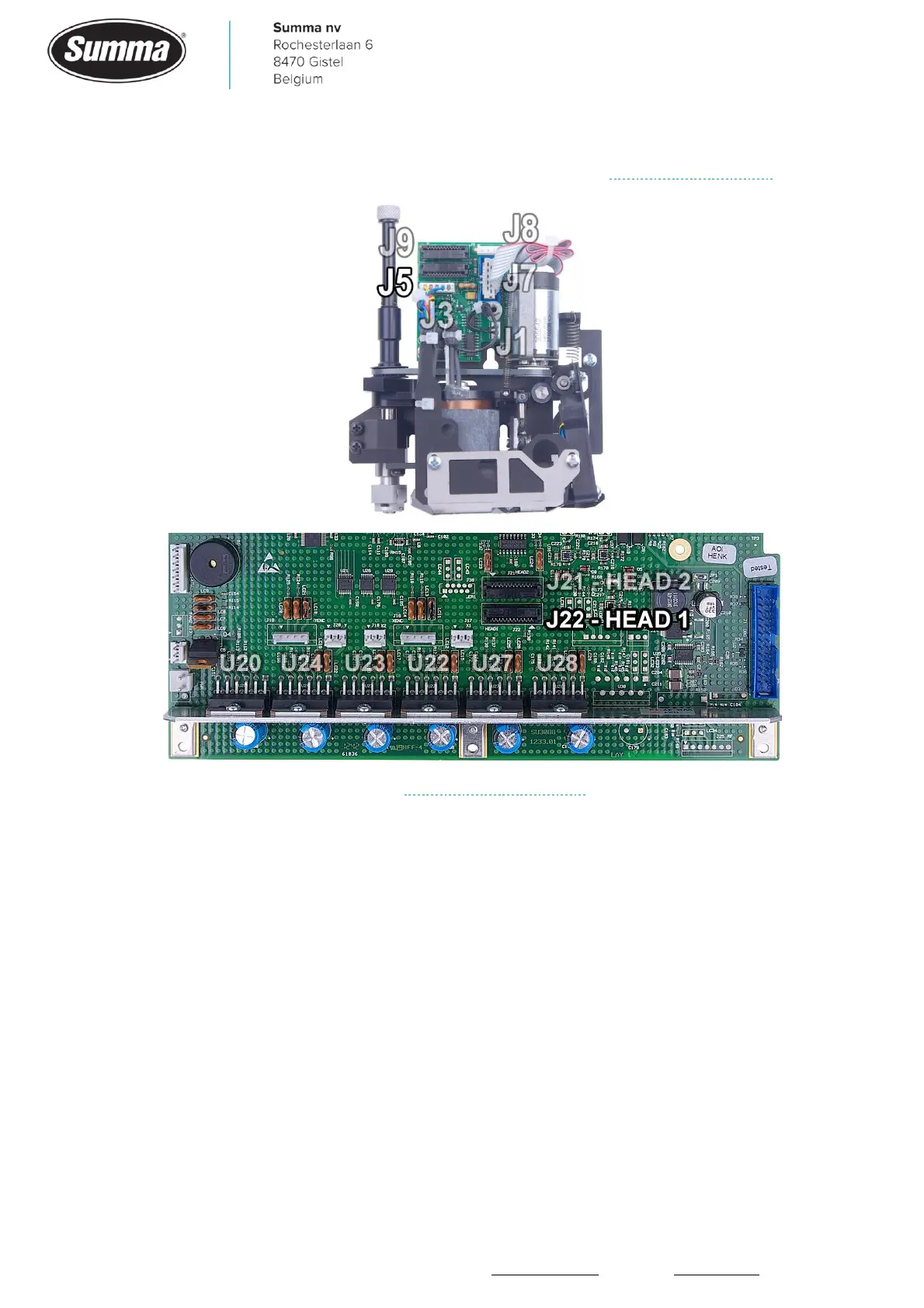

• The flat cable between the cutter head (J5) and the main board (J22: HEAD1) may be

defective, or the flat cable was not fit straight in the sockets. Replace the flat cable.

• The main board may be defective. Replace the main board.

2.6 The middle pinch roller is not set properly above a sleeve!

2.7 The left pinch roller is not set properly above a sleeve!

On loading media, and lowering the pinch rollers, the machine starts to search for the

position of the pinch rollers. The cutter head is moved up to the right side end plate to use

this as the reference position. Then the cutter head moves to the left to search the first

pinch roller position. It then searches for the middle pinch rollers, and finally for the left-

most pinch roller.

The machine may incorrectly detect the position of the middle and/or left-most pinch rollers

being set incorrectly. This could be due to the following:

• Double check for the left and/or middle pinch rollers to have been put in a click position (over

a grit roller) indicated by a small white triangle on the Y-axis guiding.

Loading...

Loading...