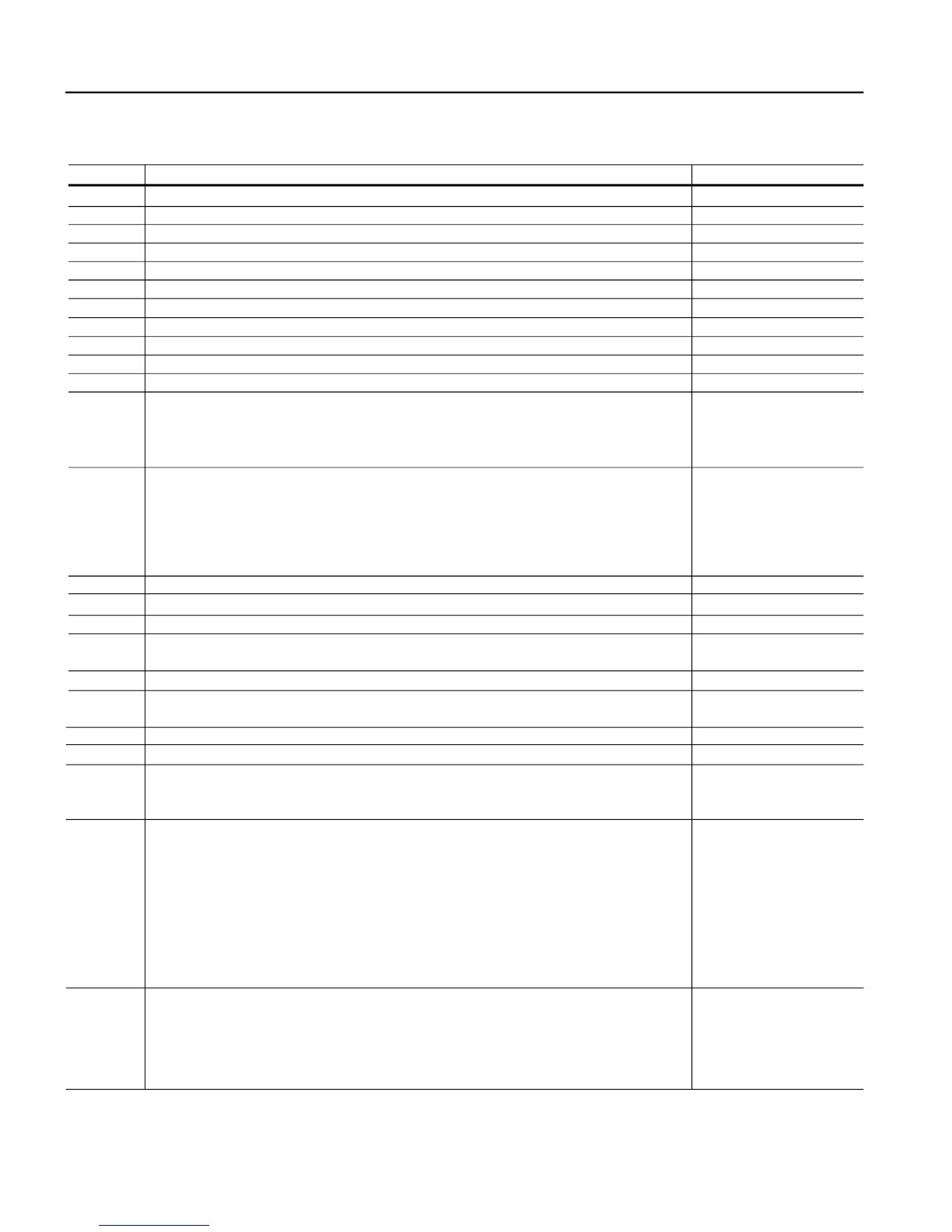

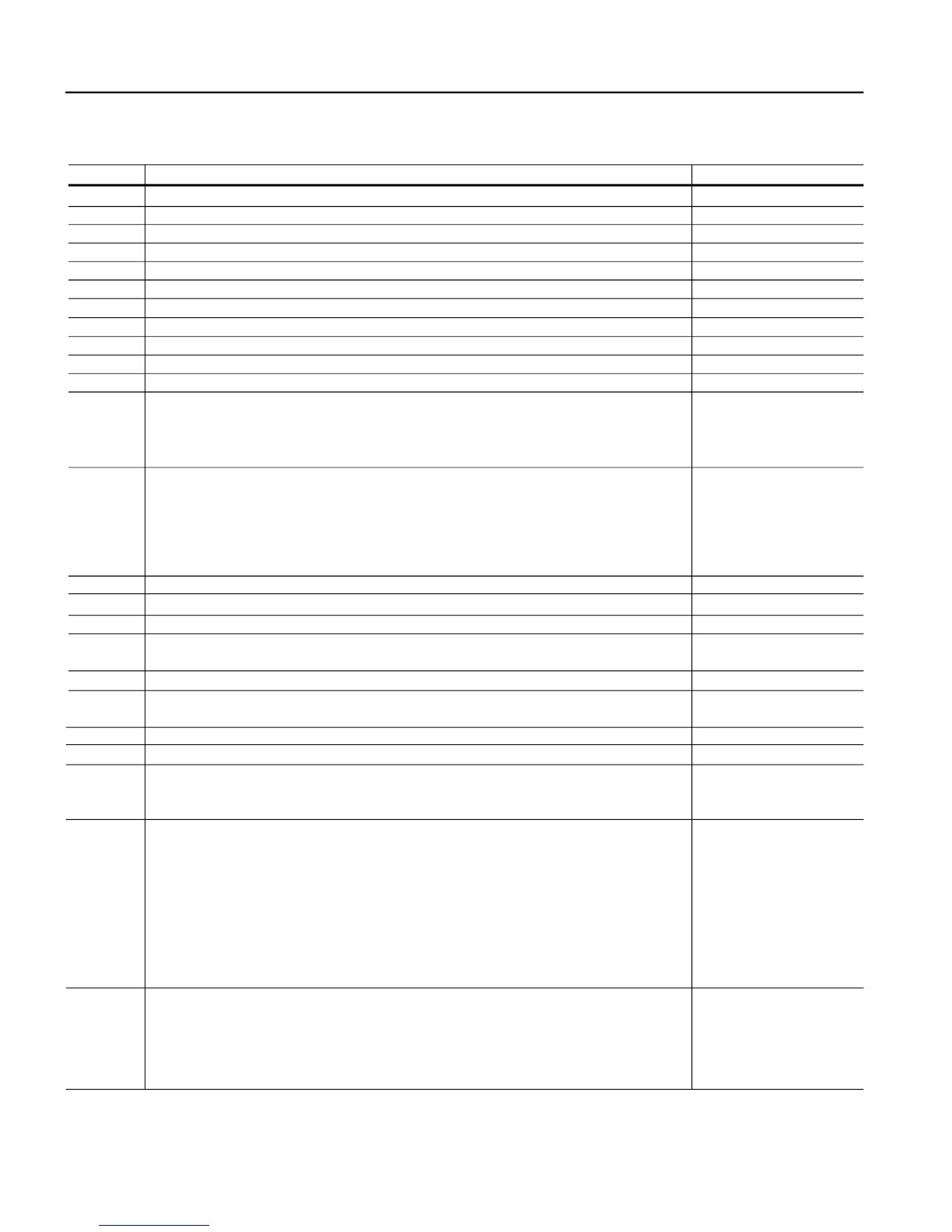

Inclusion of the functions Fieldbus and Serial Communication.

Inclusion of the Spare Part List.

Inclusion of the PID Regulator.

Inclusion of the German Language - Ride-through and Flying

Inclusion of DBW-01; KIT KME; DC Link Inductor.

tem 3.3 - CE Installation.

Inclusion of new functions such as Ride-Through for Vector Control, Motor Phase Loss.

New I/O Expansion Boards EBB.04 and EBB.05.

Inclusion of the models from 2.9 to 32 A / 500-600 V.

3.2.1; 3.3; 4.2; 6.2; 6.3; 7.1;

7.2; 7.4; 7.5; 8.7.1; 8.10.1;

Inclusion of new functions:

Control Type of the Speed Regulator, Speed Regulator Differential Gain, Stop Mode Selection,

Access to the parameters with different content than default, Hysteresis for Nx/Ny, kWh

Counter, Load User 1 and 2 the factory Hours Hx, via DIx, Parameter Setting Disable via DIx,

Help Message for E24, “P406 = 2 in Vector Control”, Automatic SensorLess Set of P525, Last

10 errors indication, Motor Torque indication via AOx.

New optional boards: EBC and PLC1.

Newmodel CFW-09 SHARK NEMA 4X/IP56.

New models for voltages, currents and powers: Models 500-600 V.

Inclusion of the items 8.14 Modbus-RTU, 8.17 CFW-09 Supplied by the DC Link - Line HD,

8.18 CFW-09 RB Regenerative Converter.

Updating of the Spare Part List.

Inclusion of new functions:

Overcurrent Protection, Default factory reset 50 Hz, Timer Relay, Ramp Holding.

New lines of the current and

PID Regulator to “Academic” Changing.

General revision and update of the software version (2.6X to 3.1X):

Change on the maximum value of P156 and P401 for some models; Change on the maximum

value of P331; Change on the factory default value of P404.

Incorporation of the Mechanical Brake Logic for cranes, Load Detection Logic and addition of

Refer to items I, 6, 7 and 8

option “Indication of Torque Current Polarity” at the DOx and RLx outputs; VVW Control; DC

Braking for VVW and Sensorless; Flying Start function for the Sensorless Control; support for

EtherNet/IP communication board; read/write function for the PLC board parameters through

Modbus; Indication of the Analog Outputs values in read only parameters P027 to P030;

Simultaneous indication of the speed and current in parameter P070; P313 = 4 (Changes to

LOCAL mode keeping the commands);Regulation of the maximum torque current through

options AI1+AI2 and AI2+AI3; function F > Fx; function ready 2.

Updating of the software version to V4.0X.

Updating of the parameters P309 and P313.

Addition of new parameters: P335, P336, P337, P338, P340, P341, P342, P343, P344 and P346.

New options for fault Reset.

The table below describes all revisions made to this manual.

Loading...

Loading...