CHAPTER 8 - CFW-09 OPTIONS AND ACCESSORIES

For applications that require high-speed accuracy, the actual motor speed

must be fed back via motor-mounted incremental encoder. The encoder is

connectedelectricallyto the inverter through the XC9 (DB9) connector of the

Function Expansion Board - EBA or EBB and XC9 or XC10 to EBC.

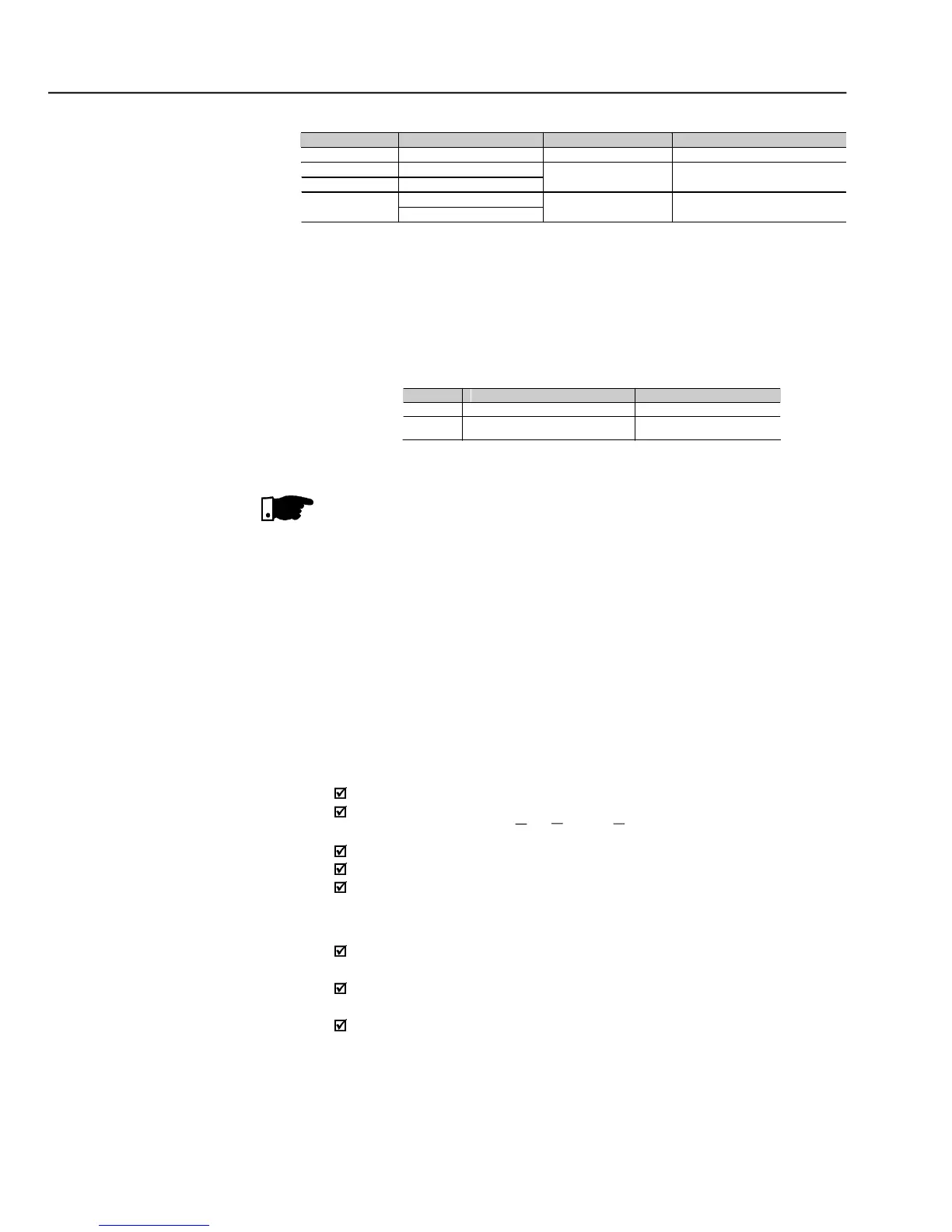

When the board EBA or EBB is used, the selected encoder should have the

following characteristics:

Power supply voltage: 12 Vdc, less than 200 mA current draw;

2 quadrature channels (90º) + zero pulse with complementary outputs

(differential): signals A, A, B, B, Z and Z;

“Linedriver” or “Push-Pull” output circuit type (level 12 V);

Electronic circuit isolated from encoder frame;

Recommended number of pulses per revolution: 1024 ppr.

For mounting the encoder on the motor, follow the recommendations bellow:

Couple the encoder directly to the motor shaft (use a flexible coupling

without torsional flexibility);

Both the shaft and the metallic frame of the encoder must be electrically

isolated from the motor (min. Spacing: 3 mm (0.119 in));

Use high quality flexible couplings to prevent mechanical oscillation or

The electrical connections must be made with shielded cable, maintaining a

minimum distance of about 25 cm (10 in) from other wires (power, control

cables, etc.). If possible, install the encoder cable in a metallic conduit.

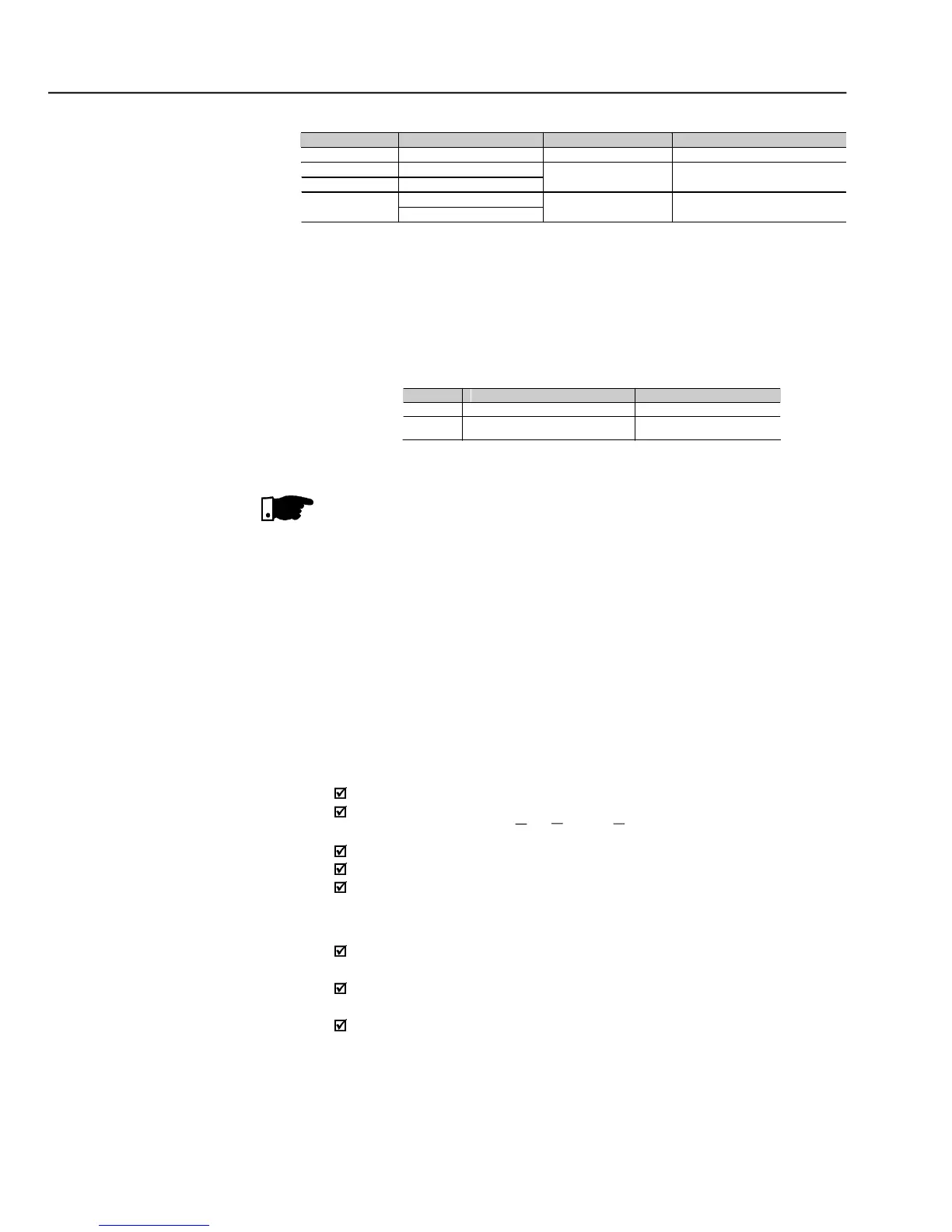

Trimpots configurations EBB board

Each group of switches must be set for the same option (ON or OFF for both).

When the outputs are set to (0 to 20) mA, it may be necessary to readjust the full scale.

For Size 1 models the CFI1 board (interface between the CC9 control board and the HMI) must

be removed to clear access to these switches.

EBB board selector switches configurations

Please download from www.weg.net the EBE Board Quick Guide.

Theexternalsignalandcontrolwiringmust beconnectedto XC(EBB),following

the same recommendations as for the wiring of thecontrol board CC9 (referto

Loading...

Loading...