5-8

POWR

E

INSPECTION

G630000-0

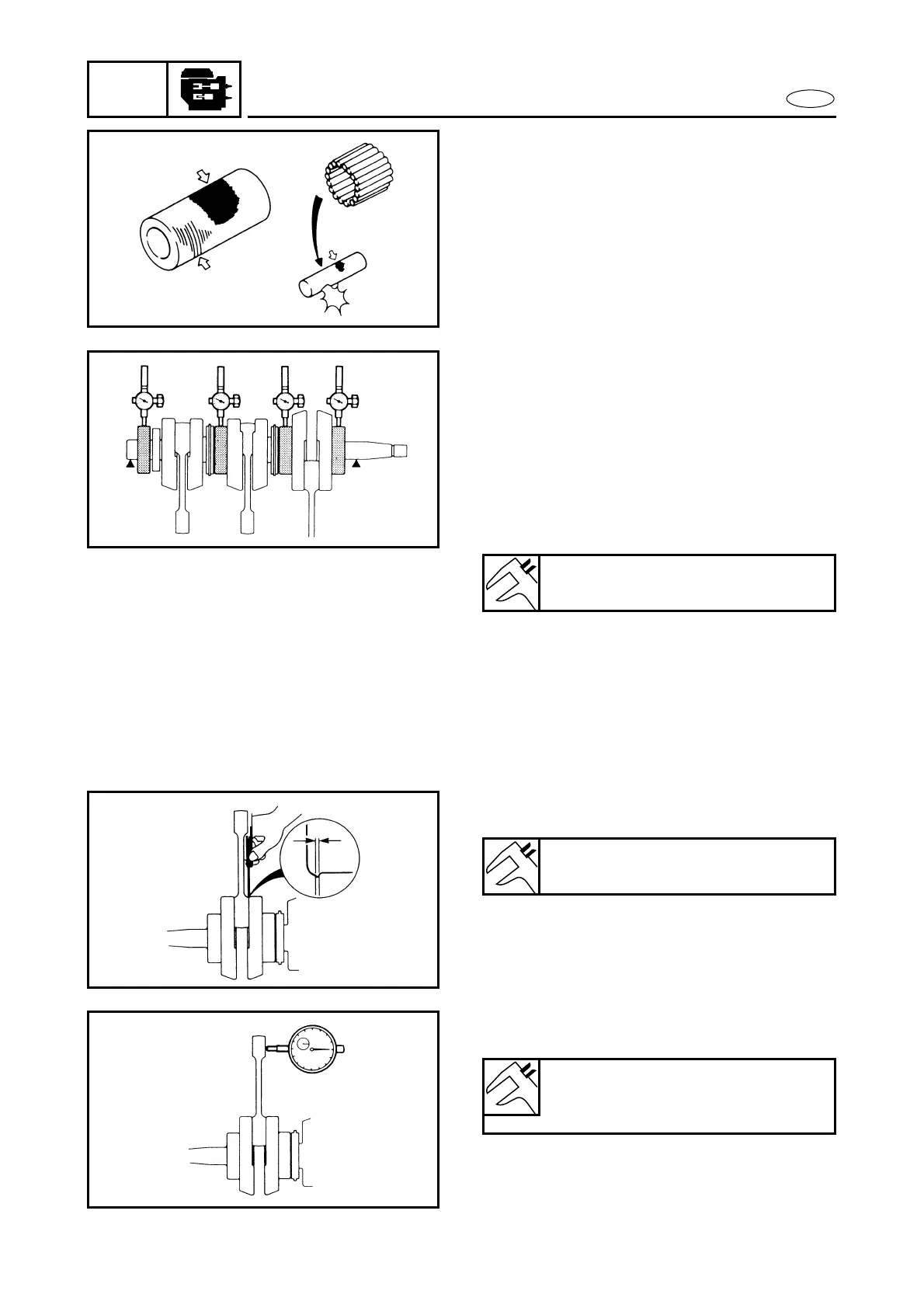

PISTON PIN AND SMALL END

BEARING

Cleaning

1. Use a soft brush and solvent to clean

the parts.

Inspection

1. Visually inspect for surface defects,

breakage, scratches and pitting. If it is

decided to replace the small end bear-

ings, replace them all.

G63502-0*

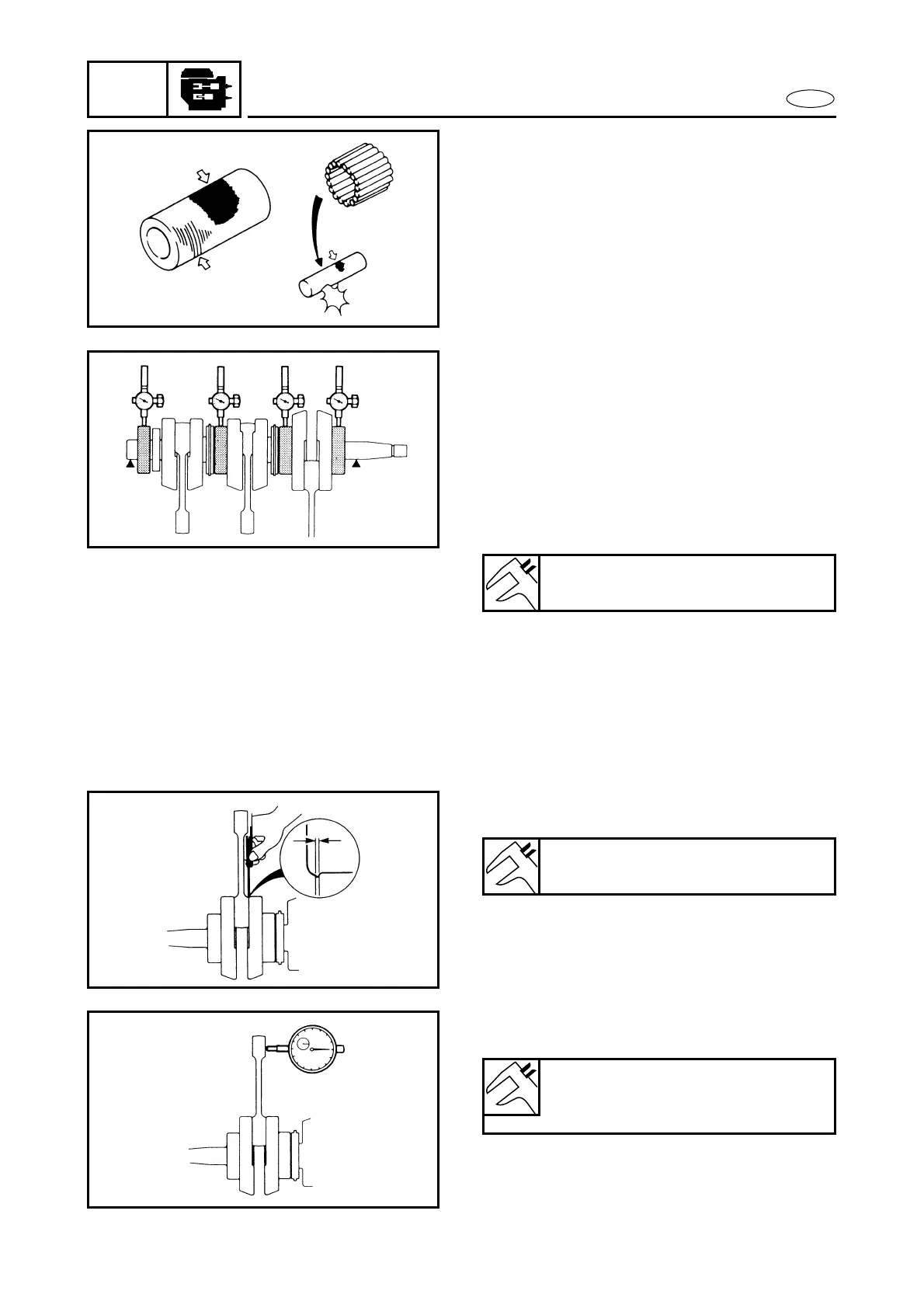

CRANKSHAFT

Inspection

1. Place the crankshaft on a crankshaft-

aligner or on V-blocks.

2. Using dial gauge, measure the deflec-

tion.

If the deflection is greater than specified

maximum, correct the alignment by use

of a copper hammer and a wedge.

Maximum deflection:

0.03 mm (0.001 in)

3. Using feeler gauges, measure the con-

necting-rod side clearance.

If this side clearance exceeds the speci-

fication, replace the crankshaft assem-

bly.

Connecting-rod side clearance:

0.2 ~ 0.7 mm (0.008 ~ 0.028 in)

4. Using a dial gauge, measure the con-

necting-rod axial play.

If this axial play is greater than the max-

imum axial play, replace the crankshaft

assembly.

Connecting rod maximum axial

play:

2.0 mm (0.08 in)

Loading...

Loading...