13185L-002 Rev. A 1/24/06 110XiIIIPlus Maintenance Manual Page 4-61

Maintenance Section 4

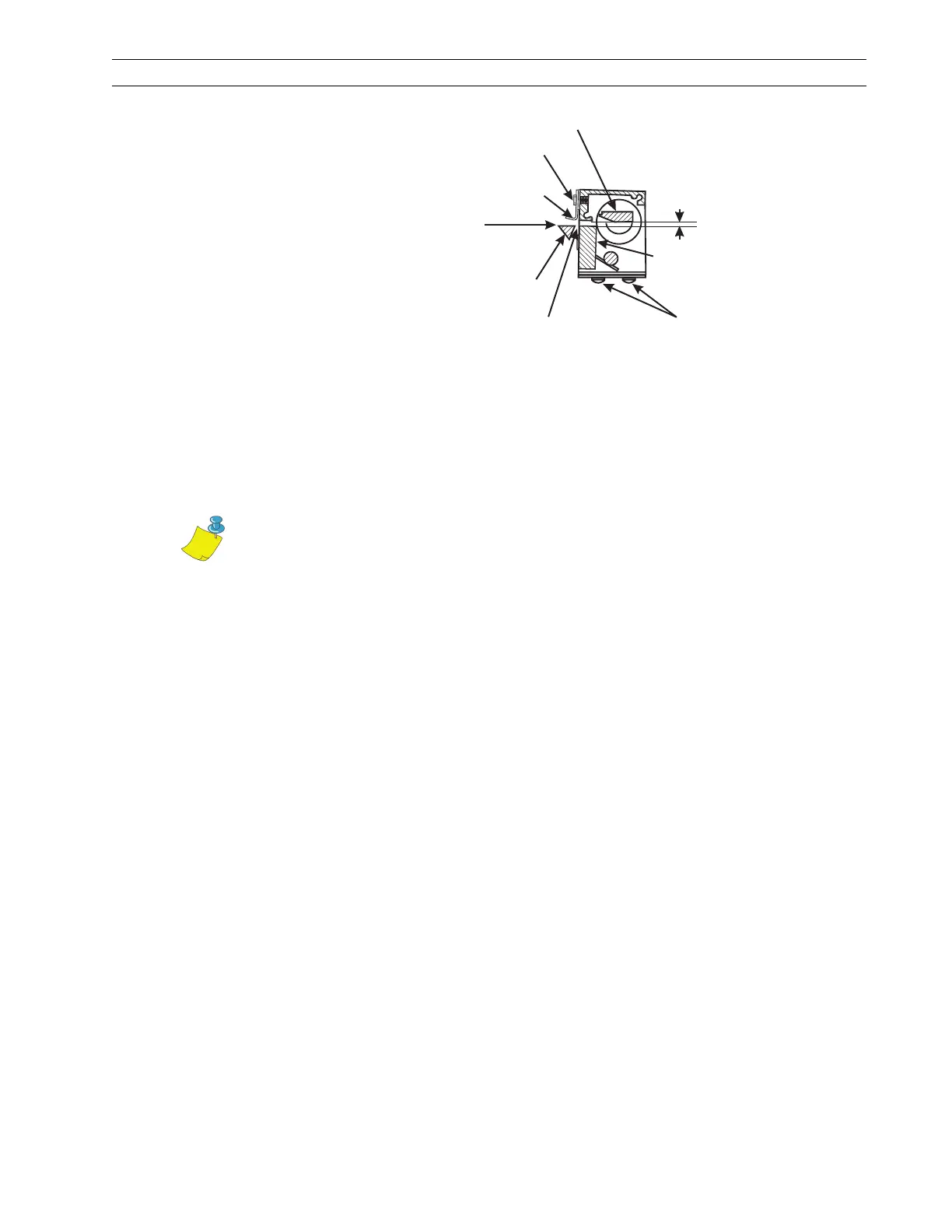

Figure 4-36. Mechanical Assembly Position

5. Position the upper drive arm out from the cutter frame so its flat surface is flush with

the end of the rotary cutter blade shaft.

6. Use an Allen wrench socket on a torque wrench and tighten the screw until the slot

closes or until a torque of 100 inch-pounds (11.3 N

•m) is achieved.

7. With a pen, draw a line across the outer face of the upper drive arm and the end of

the cutter blade shaft. If cutter operation problems occur, this mark shows whether

the alignment of the clamp and the cutter blade shaft has changed.

8. Refer to RRP No. 2 on page 4-16. Replace the electronics cover.

9. Reconnect the AC power cord and turn the printer On (l). Enter Configuration Mode

and set the printer to Cutter Mode. Save as PERMANENT and turn the printer Off

(O).

10. Load media and ribbon, press and hold PAUSE while turning the printer On (l), and

run labels through the printer. Test the cutter for proper operation.

11. Test the printer timing by feeding maximum-width label stock through the printer

and ensuring a complete cut occurs. If necessary, repeat the retiming procedure.

Rotary Cutter Blade

Upper Cutter Bracket

Mounting Screw

Media Guide

0.100 in.

(2.5 mm)

Ensure the top of the tear-off

bar is positioned above or

level with the top of the

rear cutter blade.

Tear-Off

Bar

Clearance of 0.030 in. (0.7 mm)

minimum between rear cutter blade

and tear-off bar

Screws control position

of cutter module and

squareness to media.

Rear Cutter

Blade

Relative position of the rotary cutter blade when the drive link assembly

is stopped by the optical sensor, when the power is On()inCutter Mode.l

Note • Overtightening the screw can damage the drive arm and strip the

threads.

Loading...

Loading...