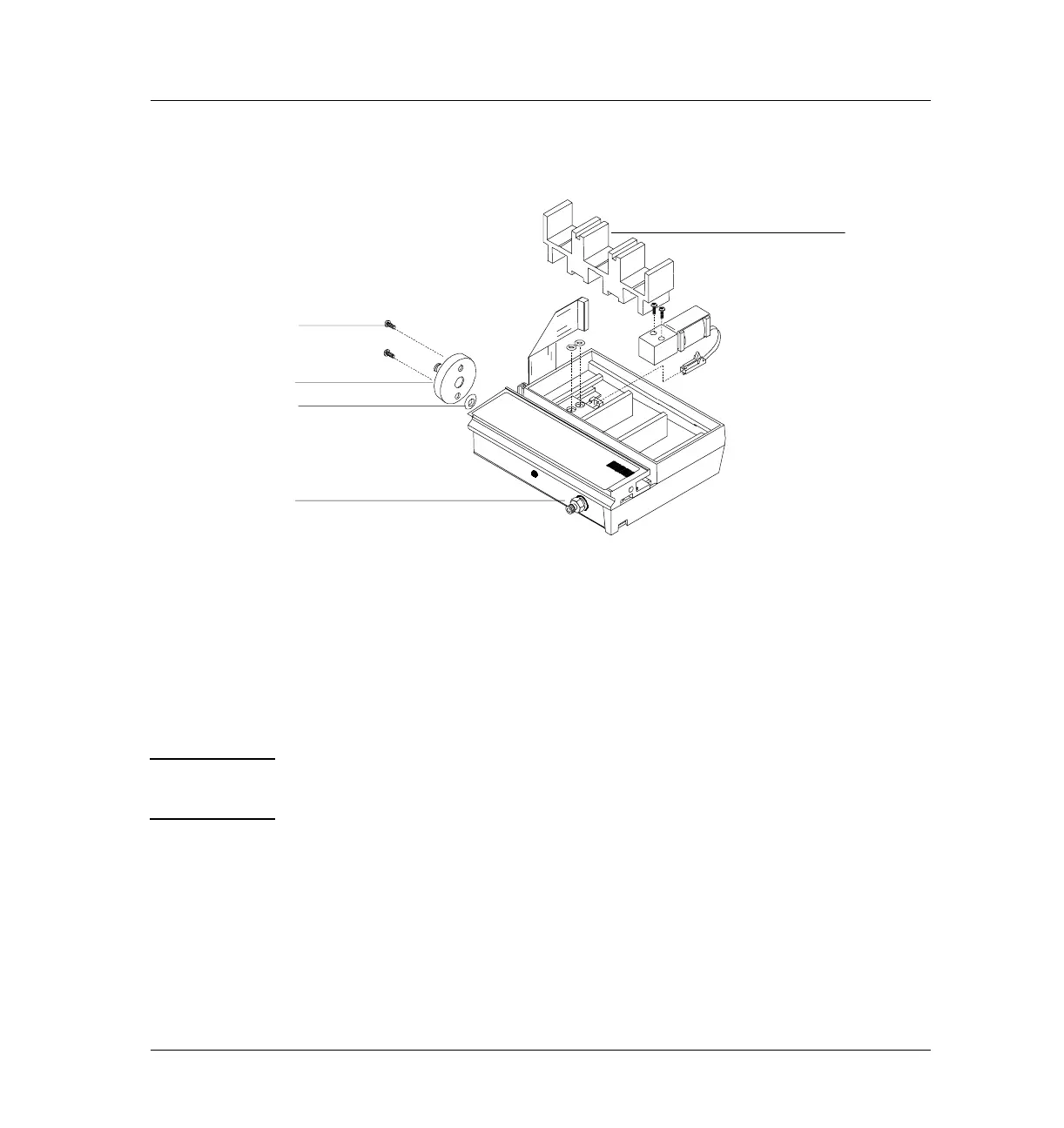

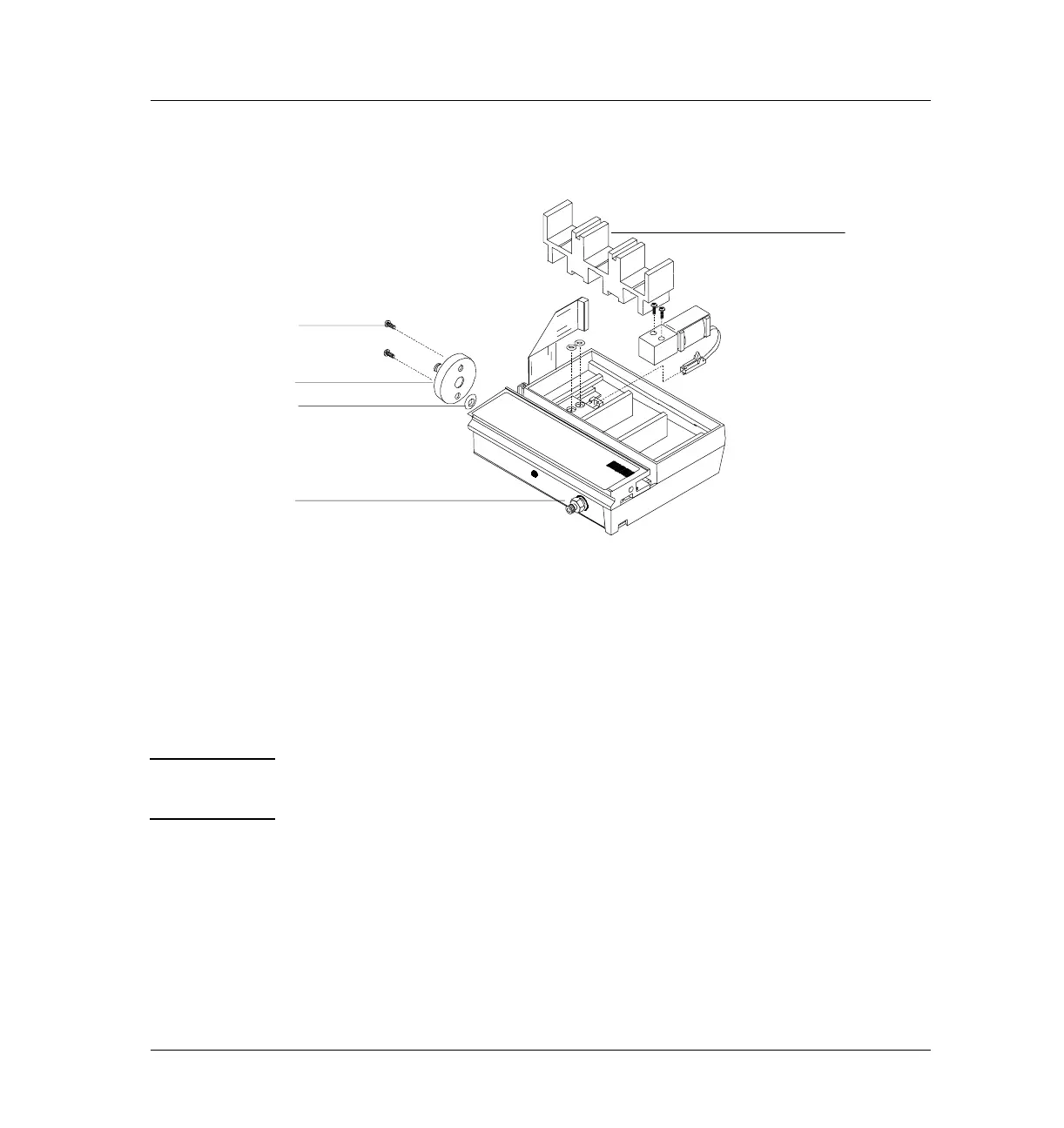

270 Pneumatics Control Module

Leak testing the PCM

10 of 10

Jun 2001

Inlets

Agilent 6890 Gas Chromatograph Service Manual

Figure 270-4

PCM serviceable parts

Correcting leaks

1. Use the electronic leak detector to check all areas of the PCM that are

potential sources of a leak.

2. Tighten any connections which are leaking and re-test.

Note If the pressure drop is now 0.05 psi/min or less, you can consider the interface

system leak–free.

3. If the interface still leaks, continue to check for and correct leaks.

Potential leak areas

Check the following areas when checking for leaks in the PCM.

• The capped purge vent

• Three O-rings behind the block where the pneumatic lines enter the PCM

• Two O-rings for each valve in the PCM

Aluminum bracket

Septum purge fitting

O-ring

Supply fitting

Screws

Caution

Aluminum bracket removed for

clarity, DO NOT completely

remove the bracket during

valve replacement.

Loading...

Loading...