19 of 30

Jun 2001

Inlets

Agilent 6890 Gas Chromatograph Service Manual

Split/Splitless Inlet 210

Leak testing—EPC and manual inlets

Leak testing—EPC and manual inlets

Preparation

1. Cool the column to ambient, and cool inlets to below 75°C to avoid

damage to deactivated glass liners.

2. Remove the column from the inlet fitting on the inside of the oven.

3. If the quality of the septum, the O-ring on the glass liner and the lower

inlet seal are unknown, replace them now.

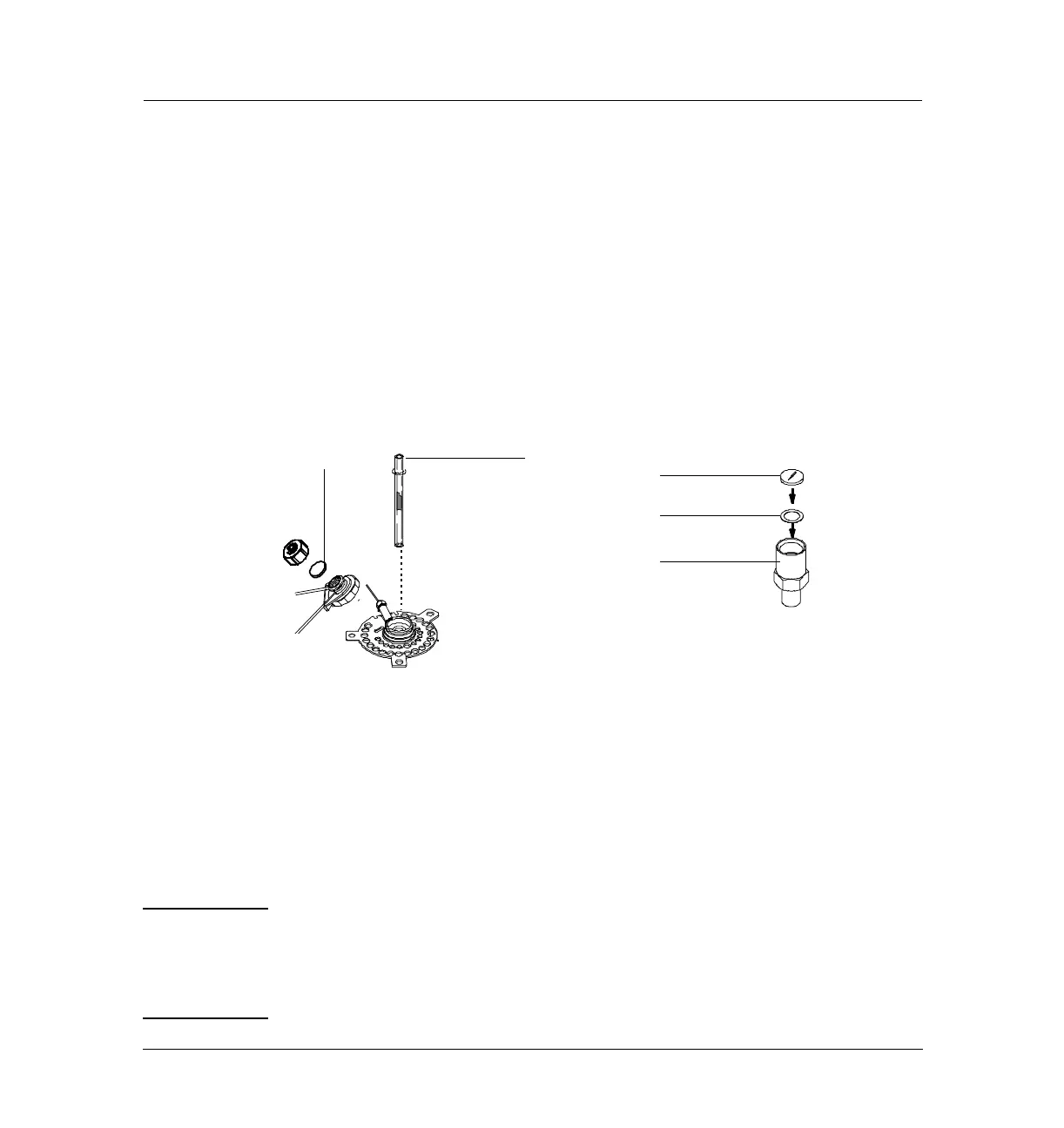

Figure 210-13 Location of septum, liner, O-ring, and lower inlet seal

4. Cap the septum purge vent and the inlet’s column fitting. Use solid (no

hole) Vespel type ferrules 1/8-inch (part no. 0100-1372) and 1/16-inch

(part no. 5181-7458) with a 1/8-inch Swagelok nut (part no. 5180-4103)

and a capillary column nut.

Note As alternate capping devices, a 1/8-inch Swagelok cap can be used for the

septum purge vent. A capillary column nut with a solid piece of wire the size

of a paper clip and a 0.5 mm ID graphite ferrule may be used for the inlet

column fitting.

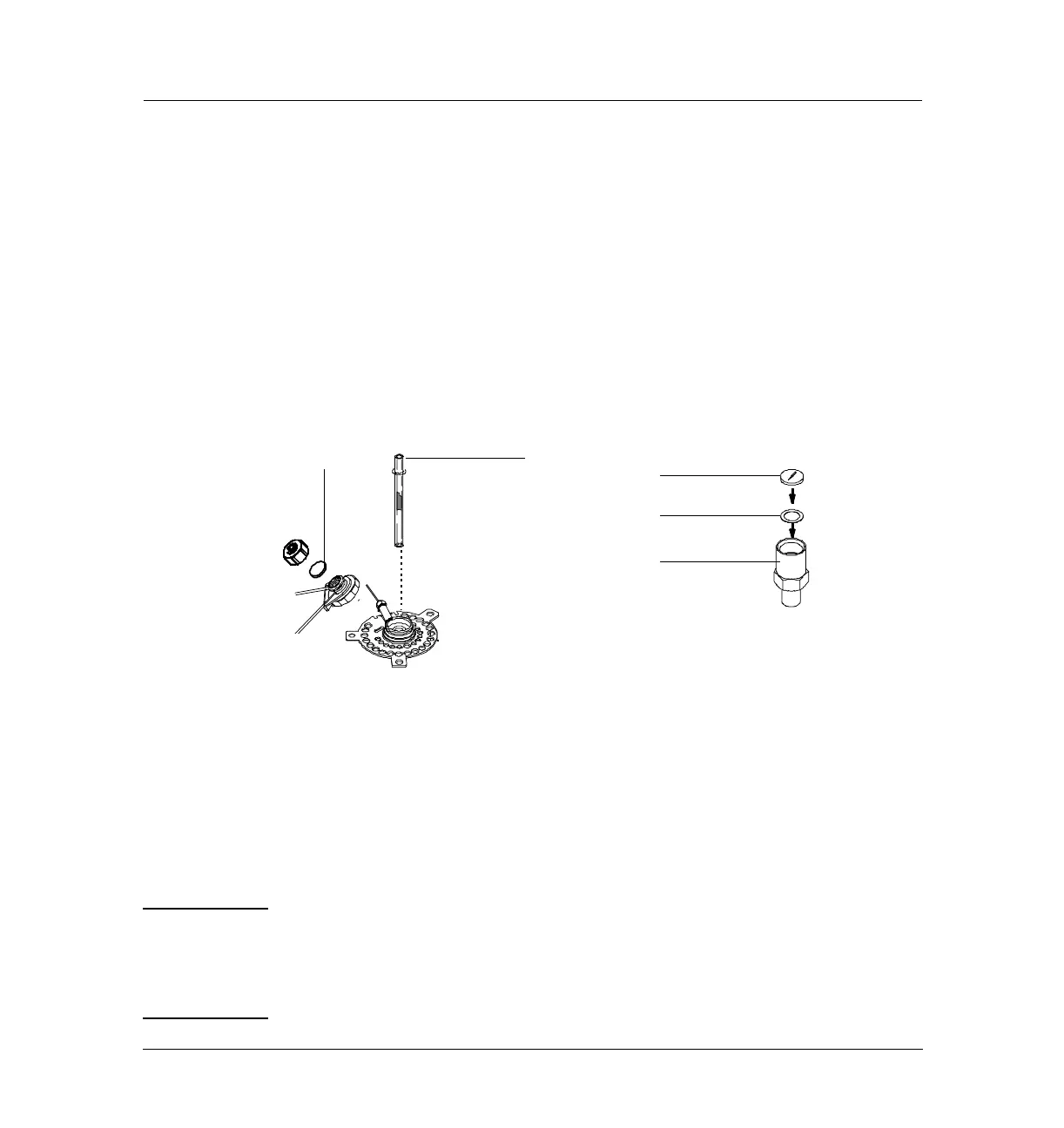

Lower inlet seal

Washer

Reducing nut

0-ring

(2-3 mm from top)

Septum

Inlet liner

Loading...

Loading...