Rockwell Automation Publication 750-UM006C-EN-P - March 2022 173

Chapter 6

Troubleshooting

Electrical Safety

Considerations

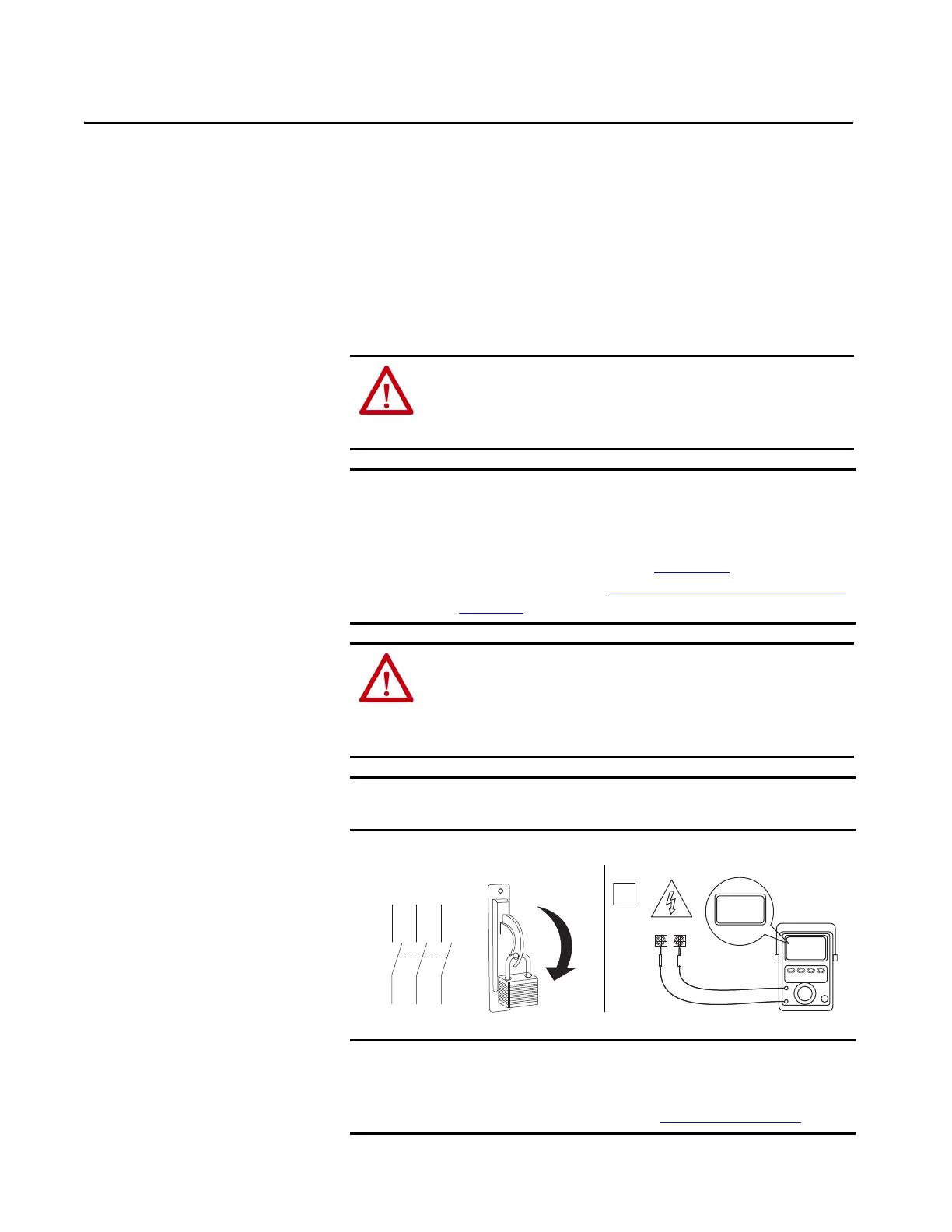

The drive is meant to be disconnected and repaired after proper lock out / tag

out procedures have been employed.

ATTENTION: To avoid electrical shock, open the appropriate upstream

protection (disconnect switch or branch circuit protection) before connecting

and disconnecting cables. To avoid an electric shock hazard, verify that the

voltage on the bus has entirely discharged before servicing.

IMPORTANT For drives that were in storage and did not have voltage applied,

maintenance of the drive may be required. For drives that are stored under

2 years, there is no additional maintenance required. For storage greater

than 2 years, see Preventive Maintenance Checklist of Industrial Control and

Drive System Equipment, publication DRIVES-TD001

for bus capacitor

reforming requirements and Maintenance of Industrial Control Equipment

on page 197 for more information.

ATTENTION: The drive contains high voltage that takes time to discharge

after removal of the main power supply. Before working on the drive, isolate

the main power supply from line inputs (L1, L2, L3). Wait 3 minutes for the

discharge to reach minimal voltage levels. Failure to do so may result in

personal injury or death.

IMPORTANT To do proper troubleshooting, you need to have the electrical schematics

available for your system.

IMPORTANT This lock out / tag out is only for upstream power. During initial installation,

the drive does not have power. The breakers should be in the OFF position

when the unit arrives. Verify that all breakers are off before maintenance is

started. For more information, see the Circuit Breakers

on page 24 section.

L1 L2 L3

O

I

Loading...

Loading...