Rockwell Automation Publication 750-UM006C-EN-P - March 2022 49

Chapter 4

Configure and Start Up the Drive

This chapter includes information to establish communication with the drive

via the embedded EtherNet/IP adapter, view adapter status via parameters,

configure the basic startup parameters, and how to set or clear a fault action via

drive parameters. For detailed information on programming, additional

startup information, and troubleshooting of the PowerFlex 755® drive, see the

PowerFlex 750-Series AC Drives Programming Manual, publication

750-PM001

.

Startup is performed by using the cover-mounted HIM, Connected

Components Workbench™ software, Drive Executive™ software, or the Logix

Designer application. Startup can also be performed by downloading a locally

stored customer template drive file that has the I/O to control the motor brake

configured.

For questions regarding this requirement contact Rockwell Automation Drives

technical support for assistance.

Prepare for Initial Drive

Startup

Gather the following information before proceeding to startup. We

recommend that you print this page and keep it available during the startup

process. See Startup Information

on page 207 in Appendix B of this document

for a printable version of this table. This information is used throughout

startup and while in the startup dialog boxes.

ATTENTION: Allen Bradley® servo motors must be uncoupled from the load

and have a rotate autotune preformed at startup to identify the

commutation offset required to produce torque properly. This test cannot be

performed with the motor coupled to the load. Failure to comply will result

in equipment damage or failure.

IMPORTANT For induction motors that can't be easily uncoupled, an alternative static

tune procedure can be used in the autotune portion of startup. However, an

uncoupled rotate tune is the recommended method for commissioning.

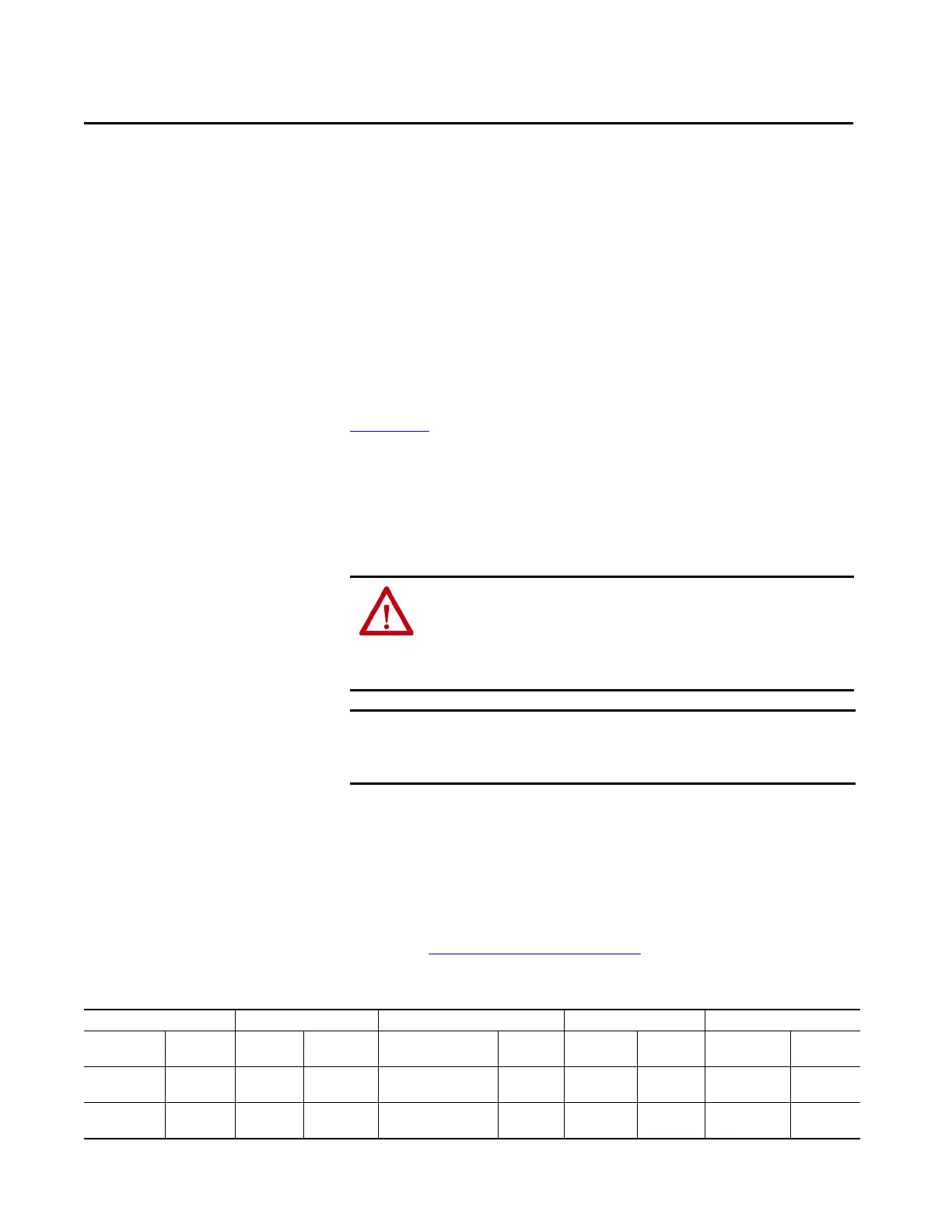

Motor Data

(1)

(2)

Dynamic Brake Data Option Module: Safety Stop Mode Application Specifics

Hp/kW Ohms (A) S3 Safe Torque Off –

Hardwired

Coast Accel Rate

Hertz Watts (A) S3 Safe Torque Off –

Integrated Safety

Ramp Stop Decel Rate

RPM Watts/sec

(joules)

(B) S4 Integrated Safe

Speed Monitoring

Current Limit S Curve

Loading...

Loading...