Manual, Air Module, AH2

Document #9620-20-D-AH2-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

D-6

5. Troubleshooting and Service Procedures

The following section provides troubleshooting information to help diagnose conditions with the Tool Changer and

service procedures to help resolve these conditions.

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from circuits in accordance with the customer’s safety practices and policies. Injury or

equipment damage can occur with the Tool not placed and energized circuits on. Place the

Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

CAUTION: Thread locker applied to fasteners must not be used more than once. Fasteners

might become loose and cause equipment damage. Always apply new thread locker when

reusing fasteners.

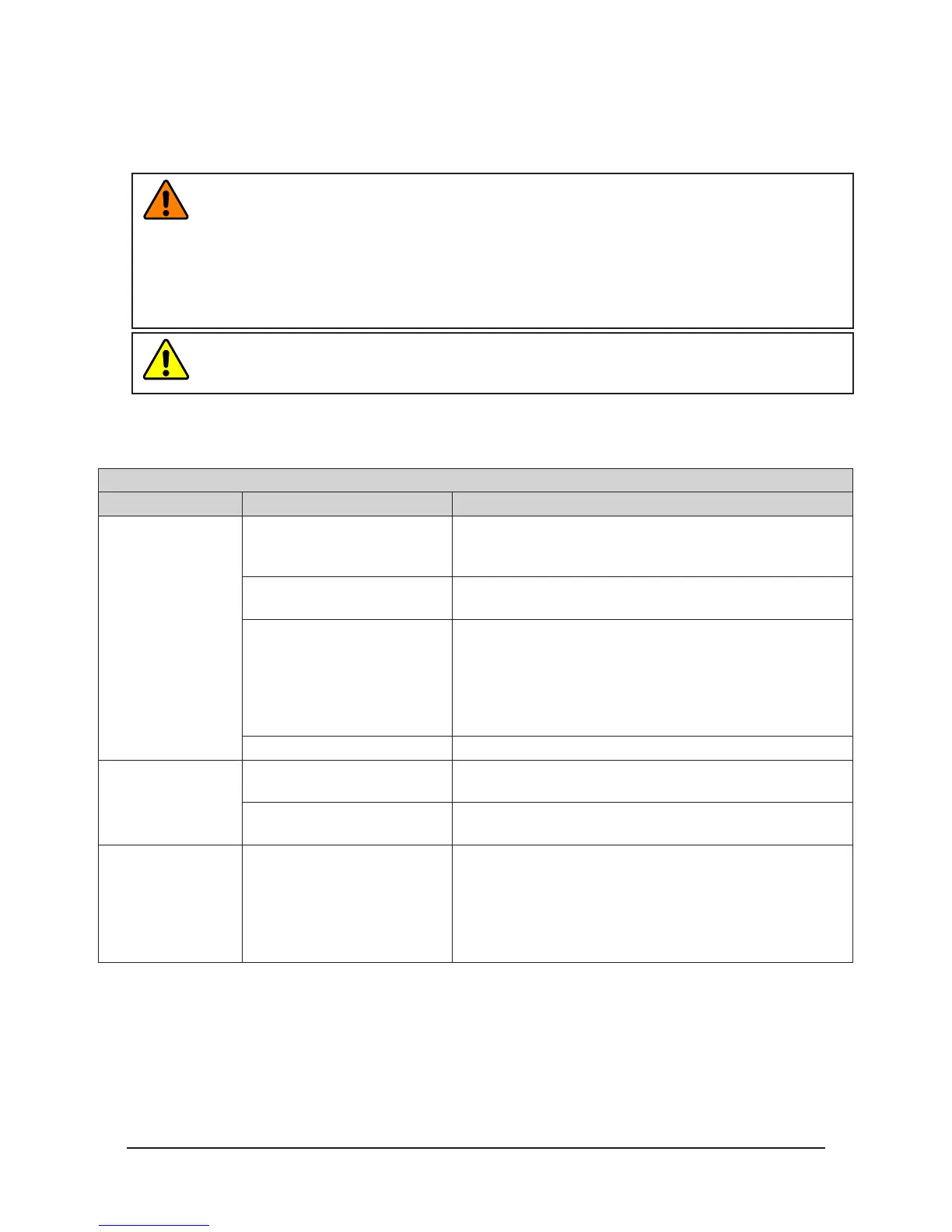

5.1 Troubleshooting

Refer to the following table for trouble shooting information.

Table 5.1—Troubleshooting Procedures

Symptom Possible Cause Correction

Air Leakage

Damaged/Worn seals

Replace O-rings as needed. Refer to

Section 5.2.1—

Master Side Self Sealing Valve and Section 5.2.2—Tool

Side Self Sealing Valve.

Debris blocking valve seal

(for self-sealing valves)

Clean in and around valve components. Ensure uid

stream is free of large particulates; lter as necessary.

Bent valve piston (for self-

sealing valves)

Replace stem. Refer to

Section 5.2.1—Master Side Self

Sealing Valve and Section 5.2.2—Tool Side Self Sealing

Valve. Check module attachment to Tool Changer.

Refer to Section 2.1—Module Installation. Check robot

program and ensure parallel approach trajectory during

Tool Changer coupling.

Corrosion Consult ATI Applications Engineering for assistance.

Reduced Air Flow

Flow path blockage

Inspect valve components and supply/return lines for

blockage. Clean/repair as necessary.

Debris blocking valve seal

(for self-sealing valves)

Clean in and around valve components. Ensure air

stream is free of large particulates; lter as necessary.

Modules unable to

Couple

Bent valve piston and/or

dowel pin (for self-sealing

valves)

Replace stem. Refer to

Section 5.2.1—Master Side Self

Sealing Valve and Section 5.2.2—Tool Side Self Sealing

Valve. Check module attachment to Tool Changer.

Refer to Section 2.1—Module Installation. Check robot

program and ensure parallel approach trajectory during

Tool Changer coupling.

Loading...

Loading...