Quick Change Installation and Operation Manual

Document #9620-20-E-ED15-04

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

E-7

5. Troubleshooting and Service Procedures

The following section provides troubleshooting and service information to help diagnose conditions and repair the

Tool Changer or control/signal module.

DANGER: This module has a voltage of 50 V or greater, NO contact should be attempted

before removing power. This especially includes separation or insertion of the mating

connectors or any contact with the Tool Changer or its components. Arcing and damage will

occur if this is not observed. Remove power before attaching, disconnecting any cables or

attempting any maintenance of Tool Changer.

WARNING: Do not perform maintenance or repair on Tool Changer or modules unless the

Tool is safely supported or docked in the tool stand and all energized circuits (e.g., electrical,

air, water, etc.) have been turned off. Injury or equipment damage can occur with Tool not

docked and energized circuits on. Dock the Tool safely in the tool stand and turn off all

energized circuits before performing maintenance or repair on Tool Changer or modules.

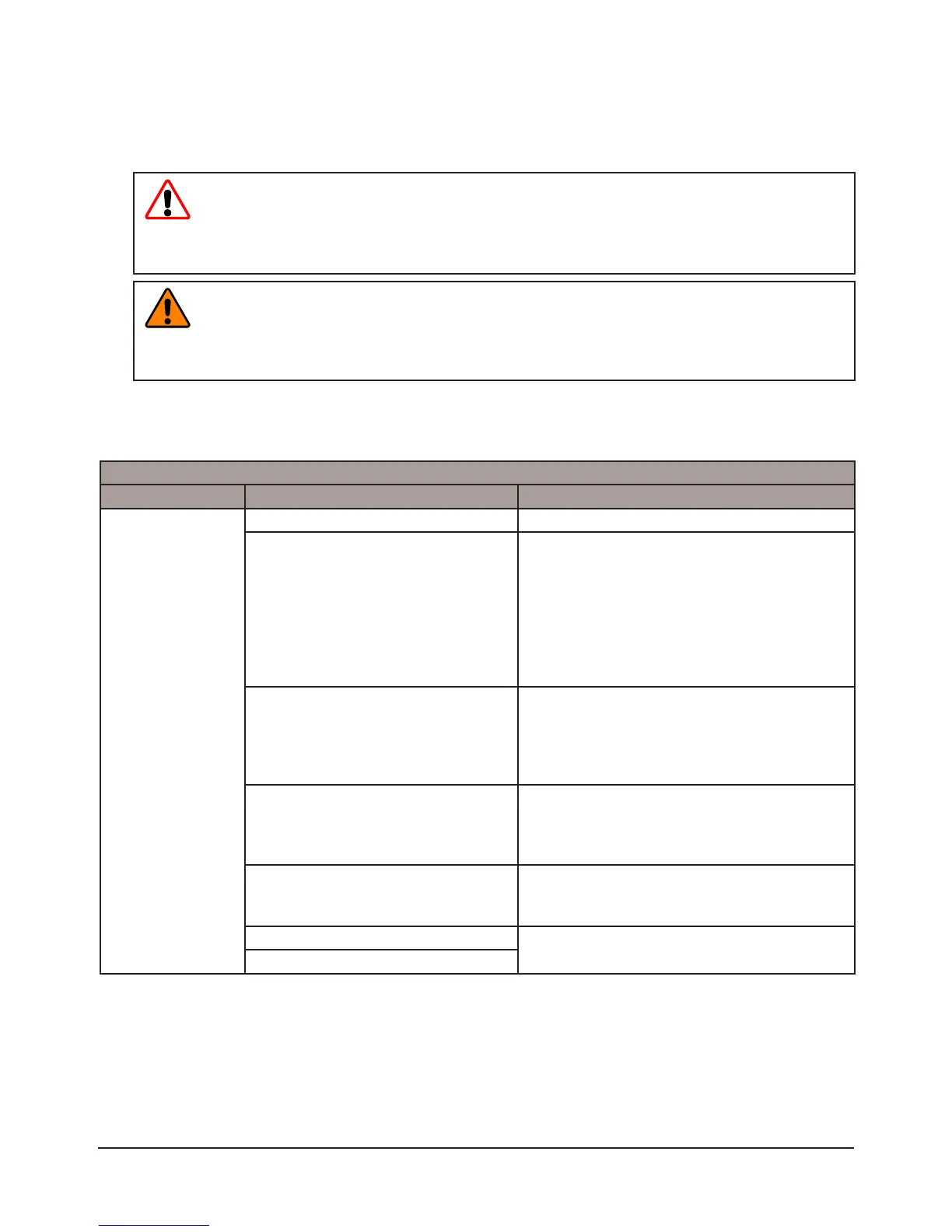

5.1 Troubleshooting

The troubleshooting table is provided to assist in diagnosing issues that may cause the Tool Changer not to

function properly.

Table 5.1—Troubleshooting

Symptom Possible Cause Correction

Signal(s)

intermittently

functioning or not

functioning at all

Object trapped between modules Remove object, then re-attempt coupling.

Servo module contact pin

contamination

Ensure that the spring pins on the Master-

side can move freely and are not bound by

debris. Clean the spring pins to restore free

operation. Clean Tool-side module contacts,

refer to

Section 4.1—Pin Block Inspection

and Cleaning. Inspect seal, replace if

damaged refer to Section 5.2.1—V-ring Seal

Replacement

Contact pin separation due to air

supply to Tool Changer

Ensure that the Tool Changer has proper

pneumatic connections and air is supplied

to proper specication. Refer to Tool

Changer section of this manual for air supply

requirements.

Coupling/uncoupling Tool Changer

under load

Revise operating procedures to only couple/

uncouple with power disconnected and

discharged. Field replacement of module

contacts is not possible.

Cable damage: Pinched, torn, or

fatigued cables

Examine cables for damage, perform a

continuity test on cables and replace any bad

cables.

Servo module damaged

Refer to

Section 5.1.1—Servo Module, Drive,

or Motor Troubleshooting Procedure.

Drive or motor damaged

Loading...

Loading...