Manual, Air Adapters

Document #9620-20-C-Jxx Air Adapters-02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

C-9

3. Operation

It is important that the air adapter be supplied with clean, dry, non-lubricated air supplied between 60 and 100 psi

(4.5–6.9 Bar) and ltered at 40 microns or better. The Tool Changer is operated by supplying air to the lock port or

the air adapter to lock the Tool Changer. The Lock air must be maintained during operation and the unlock air must

be vented to the atmosphere using a 2-position 4-way or 5-way valve, refer to Section 2.7—Pneumatic Connections

for more information. To Unlock the Tool Changer air must be supplied to the unlock port on the air adapter and the

lock air must be vented to the atmosphere.

4. Maintenance

Air adapters should require no maintenance. There are no wear components, the sensor connections should be

inspected for looseness and tighten if necessary. Pneumatic connection should be inspected for leaks or damage to

hoses.

WARNING:Do not perform maintenance or repair on Tool Changer or modules unless the

Tool is safely supported or docked in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections purged and power discharged from

circuits in accordance with the customer’s safety practices and policies. Injury or equipment

damage can occur with Tool not docked and energized circuits on. Dock the Tool safely in the

tool stand, turn off and discharge all energized circuits, purge all pressurized connections,

verify all energized circuits are de-energized before performing maintenance or repair on Tool

Changer or modules.

5. Troubleshooting and Service Procedures

The following section provides troubleshooting information to help diagnose conditions with the Tool Changer or

air adapter and service procedures to help resolve these conditions.

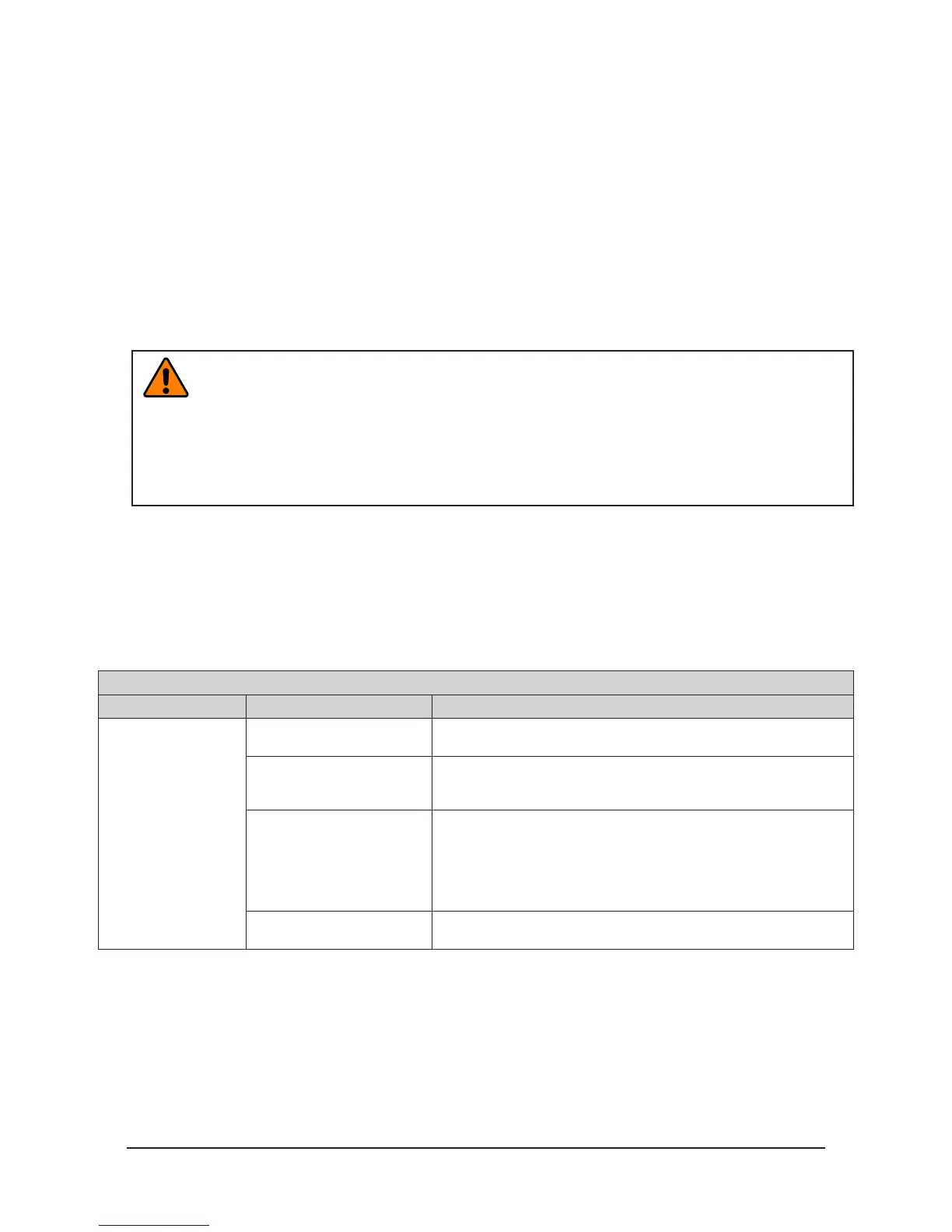

5.1 Troubleshooting

Follow the suggested actions listed in Table 5.1 when attempting to troubleshoot the air adapter. If issues persist,

contact your closest ATI representative.

Table 5.1—Troubleshooting

Symptom Cause Resolution

Tool Changer will

not Lock / Unlock or

operates slowly.

Customer supplied exhaust

mufer is clogged.

Check/Replace exhaust mufer; ensure clean air supply.

No or not enough air

pressure on the pneumatic

connection.

Make sure Pneumatic connection has minimum pressure, refer to

Section 2.7—Pneumatic Connections.

Loose air adapter or O-rings

leaking or missing.

Verify that the fasteners connecting the control/signal Module to the

air adapter are properly tightened. If air still leaking, remove the air

adapter from the Tool Changer and check for air leaks, damaged

or missing O-rings., Refer to

Section 2.2—Air Adapter Removal for

QC-113, QC-210, QC-213, GL6L, GL7L0 or Section 2.4—Air Adapter

Removal for QC-310, QC-313, QC-510, QC-1210

Customer supplied solenoid

valve not operating properly

Check customer supplied solenoid valve for damage, proper venting,

refer to

Section 2.7—Pneumatic Connections.

5.2 Service Procedures

There are no specic service procedures for the air adapter.

Loading...

Loading...