Manual, Air Module, AH2

Document #9620-20-D-AH2-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

D-3

2. Installation

The air modules are typically installed on the Tool Changers by ATI prior to shipment. The following steps outline

eld installation or removal as required. For detail information refer to Section 8—Drawings.

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from circuits in accordance with the customer’s safety practices and policies. Injury or

equipment damage can occur with the Tool not placed and energized circuits on. Place the

Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

WARNING: All pneumatic ttings and tubing must be capable of withstanding the repetitive

motions of the application without failing. The routing of electrical and pneumatic lines must

minimize the possibility of over stressing, pullout, or kinking the lines. Failure to do so can

cause critical electrical and/or pneumatic lines to malfunction and might result in injury to

personnel or damage to equipment.

CAUTION: Thread locker applied to fasteners must not be used more than once. Fasteners

might become loose and cause equipment damage. Always apply new thread locker when

reusing fasteners.

CAUTION: Air supply should be clean, dry, and non-lubricated. Supply pressure must not

exceed 100 psi and should be ltered minimum 40 micron. Connection lines must be properly

strain relieved.

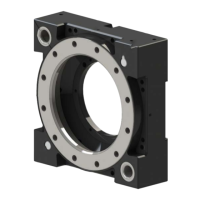

2.1 Module Installation

Tools required: 5 mm Allen wrench (hex key), torque wrench

Supplies required: Clean rag, Loctite

®

242

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

4. Clean the mounting surface on the Tool Changer or Utility Coupler.

5. Place the module into the appropriate location on the Tool Changer or Utility Coupler body. Align the

module with the Tool Changer using the dowels in the bottom of the ledge feature.

6. Apply Loctite 242 to the supplied M6 socket head cap screws. Using a 5 mm Allen wrench, install the

(2) M6 socket head cap screws securing the module to the Tool Changer or Utility Coupler and tighten to

89 in-lbs (10.0 Nm).

7. Connect air plumbing to the module. Ensure that the connectors are clean.

8. After the procedure is complete, resume normal operation.

Loading...

Loading...