Manual, Air Adapters

Document #9620-20-C-Jxx Air Adapters-02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

C-4

2. Installation

Air adapters and tool adapter assemblies are typically installed by ATI prior to shipment. The steps below outline

the eld installation or removal as required.

WARNING: Do not perform maintenance or repair on Tool Changer or modules unless

the Tool is safely supported or docked in the tool stand, all energized circuits (e.g.

electrical, air, water, etc.) are turned off, pressurized connections purged and power

discharged from circuits in accordance with the customer’s safety practices and

policies. Injury or equipment damage can occur with Tool not docked and energized

circuits on. Dock the Tool safely in the tool stand, turn off and discharge all energized

circuits, purge all pressurized connections, verify all energized circuits are de-energized

before performing maintenance or repair on Tool Changer or modules.

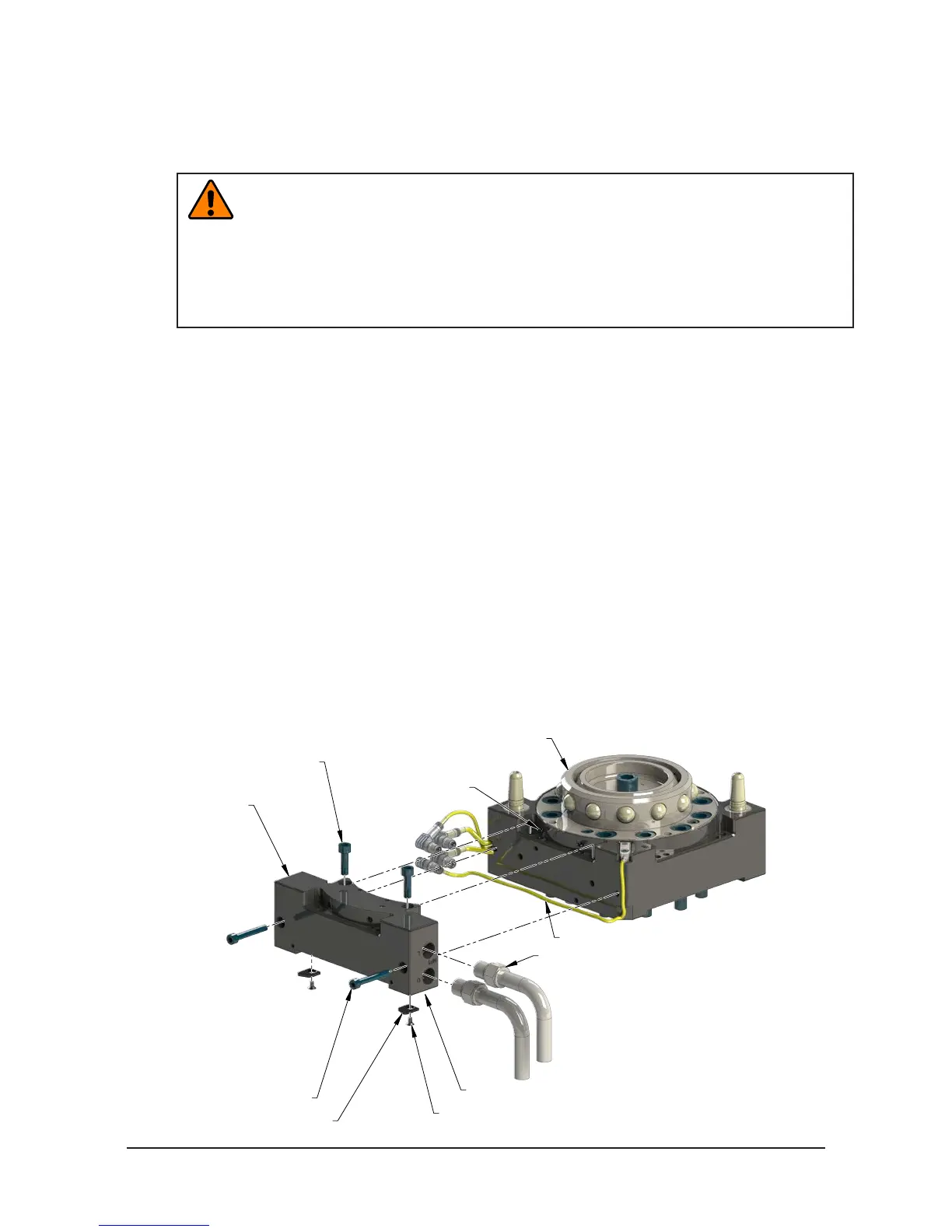

2.1 Air Adapter Installation for QC-113, QC-210, QC-213, GL6L, GL7L

Tools required: 5 mm Allen wrench (hex key), , 4 mm Allen wrench (hex key), torque wrench

Supplies required: clean rag

1. If the Tool Changer is already installed, dock the Tool side of the Tool Changer safely in the tool stand

and uncouple the Tool Changer to allow clear access to the Master and Tool plates of the Tool Changer.

2. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

3. It may be necessary to clean the mounting surface on the Tool Changer prior to installing the valve

adapter in order to remove any debris that may be present.

4. (2) O-rings are required on the Master side Flat ‘A’ interface. Make sure these O-rings are present and

lightly lubricated (refer to Figure 2.1).

5. Using the ledge feature as a guide place the air adapter adjacent to the ‘Flat A’ mounting surface. Align

the air adapter using the dowels in the bottom of the ledge feature. Apply Loctite 242 to the supplied M6

socket head cap screws. Secure the air adapter using the M6 socket head cap screws and tighten to 70

in-lbs (7.9 Nm).

6. Apply Loctite 222 to the (2) supplied M5 socket head cap screws. Secure the air adapter using the

fasteners, tighten to 55 in-lbs (6.2 Nm).

Figure 2.1—Air Adapter Installation (QC-210 Shown)

Air Adapter

9121-JA2-M

(2) M6 Socket

Head Cap Screws

(2) M5 Socket

Head Cap Screws

(2) O-rings

Tool Changer Master

(QC-210 Shown)

RTL (R1) Sensor Cable

Pneumatic Connections

(2) Cable Retaining Tabs

(2) M3 Socket Flat Head Cap Screws

Cable Channel in Bottom of Air Adapter Module

(Shown)

Loading...

Loading...