Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-10

2.5 Tool Plate Installation (includes Bolt-Down Plate)

Tools required: 8 mm, 10 mm, or 12 mm Allen wrench (hex key), torque wrench

Supplies required: Clean rag, Loctite 242

1. Clean the mounting surfaces.

2. If required, install the tool interface plate to the customer tooling, align using the boss or dowel pins and

secure with customer supplied fasteners.

3. Align the dowel pins to the corresponding holes in the Tool plate and secure the Tool plate to the tool

interface plate or customer tooling with customer supplied fasteners. Refer to Section 8—Drawings for

mounting pattern. Apply Loctite 242 to threads (see Table 2.1).

NOTICE: If an ATI interface plate is used, fasteners to mount the Tool plate is supplied with the

interface plate.

4. Connect utilities to the appropriate module and Tool plate connections.

5. After the procedure is complete, resume normal operation.

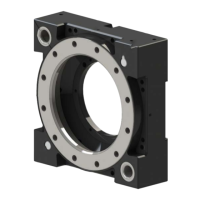

Figure 2.2—Standard Tool Plate Installation (210CT Shown)

Tool Plate

Dowel Pin (Customer Supplied)

Tool Interface Plate

(Customer Supplied)

(6) M10-1.5 Socket Head Cap Screw

Torque to 52 N-m (38 ft-lbs)

(Customer Supplied)

Loading...

Loading...