Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-23

5. Troubleshooting and Service Procedures

The following section provides troubleshooting and service information to help diagnose conditions and repair the

Tool Changer or control/signal module.

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from the circuits in accordance with the customer’s safety practices and policies. Injury or

equipment damage can occur with the Tool not placed and energized circuits on. Place the

Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

5.1 Troubleshooting Procedures

The troubleshooting table is provided to assist in the diagnosing issues that may cause the Tool Changer not

to function properly.

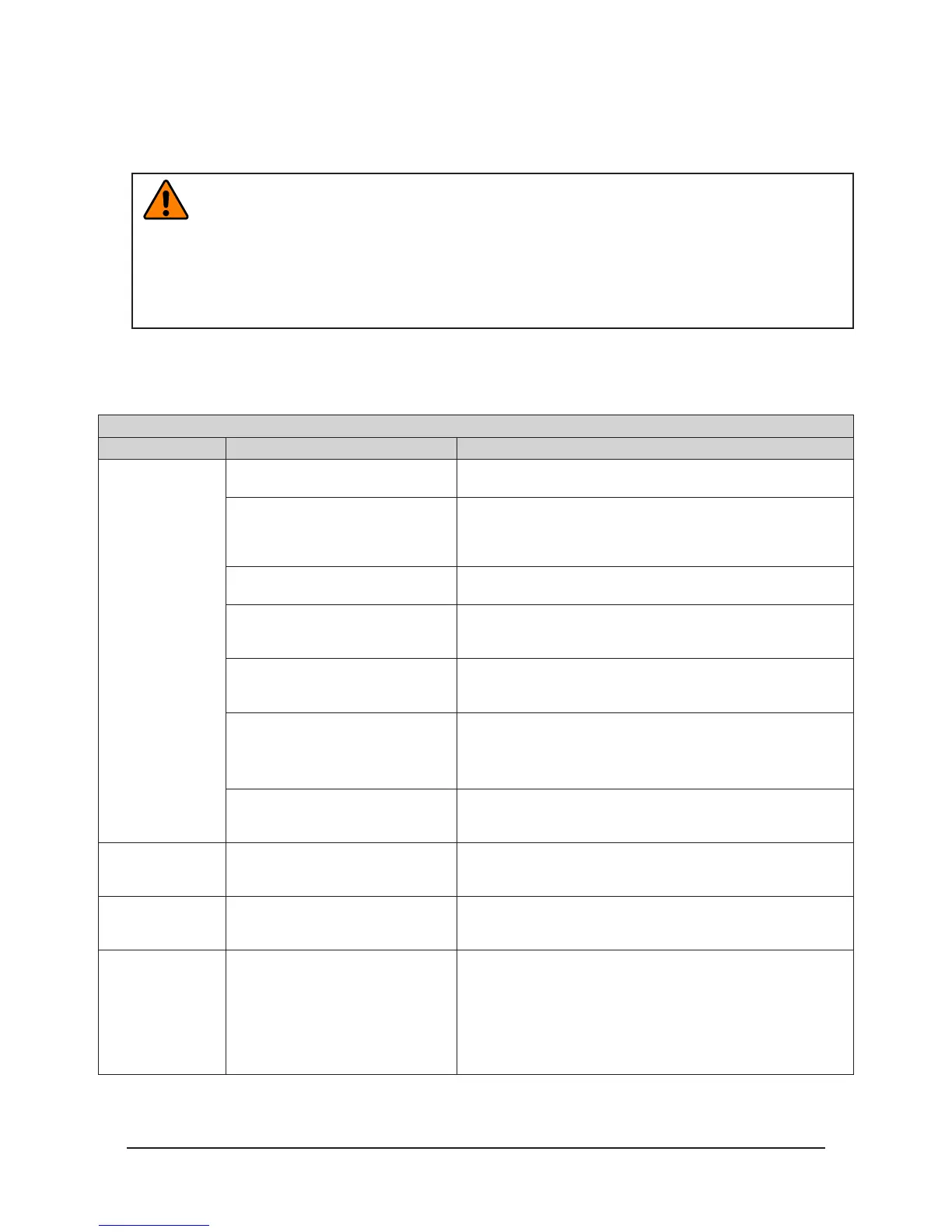

Table 5.1—Troubleshooting

Symptom Cause Resolution

Tool Changer will

not lock and/or

unlock (or Lock

sensor does not

indicate Tool

Changer is Locked)

Insufcient or no air pressure supply

to the lock or unlock ports.

Verify proper air pressure and pneumatic valve is supplied. Refer

to

Section 2.7—Pneumatic Requirements.

Air pressure trapped in the de-

energized Lock or Unlock ports.

Air pressure must be vented to the atmosphere properly,

refer to

Section 2.7—Pneumatic Requirements or refer to the

troubleshooting section of the air/valve adapter manual for more

information.

Pneumatic connections loose or

damaged, solenoid cable damaged.

Refer to the air/valve adapter manual for more information.

Debris caught between the Master

and Tool plates.

Clean debris from the between Master and Tool plates. Verify

mounting fasteners is secure and does not protrude above the

mating surfaces.

The ball bearings and/or cam are not

moving freely in the male coupling.

Clean and lubricate as needed to restore smooth operation (see

Section 4.2—Cleaning and Lubrication of the Locking Mechanism

and Alignment Pins)

The Master plate and Tool plate are

not within the specied No-Touch

zone when attempting to lock.

Check that the Tool is properly seated in the tool stand. Refer to

Section 3.5—Tool Storage Considerations.

Re-teach the robot to bring the Master plate and Tool plate closer

together prior to attempting to lock.

The control/signal module or air/

valve adapter is not operating

correctly.

Check the troubleshooting section of the manual for the specic

module.

Unit is locked but

Lock signal does

not read “on”.

Lock sensor/cable is damaged.

Replace the lock sensor assembly as necessary. Refer to

Section 5.2.1—Sensor Replacement Procedures.

Unit is unlocked but

Unlock signal does

not read “on”

Unlock sensor/cable is damaged.

Replace the unlock sensor assembly as necessary. Refer to

Section 5.2.1—Sensor Replacement Procedures.

Read-To-Lock

(RTL) does not

read “on” when

Master and Tool

plates are mated.

Ready-To-Lock (RTL) sensors

not activated indicating Tool is not

positioned properly.

Re-teach the robot to bring the Master plate and Tool plate

closer together prior to attempting to lock. Refer to

Section 3—

Operation

Check that both RTL sensors and cables are not damaged and

sensor connection to the control/signal module or air adapter

are tight. Replace damaged RTL sensors as necessary. Refer to

Section 5.2.1—Sensor Replacement Procedures.

Loading...

Loading...