PLC

9836 3521 01 223

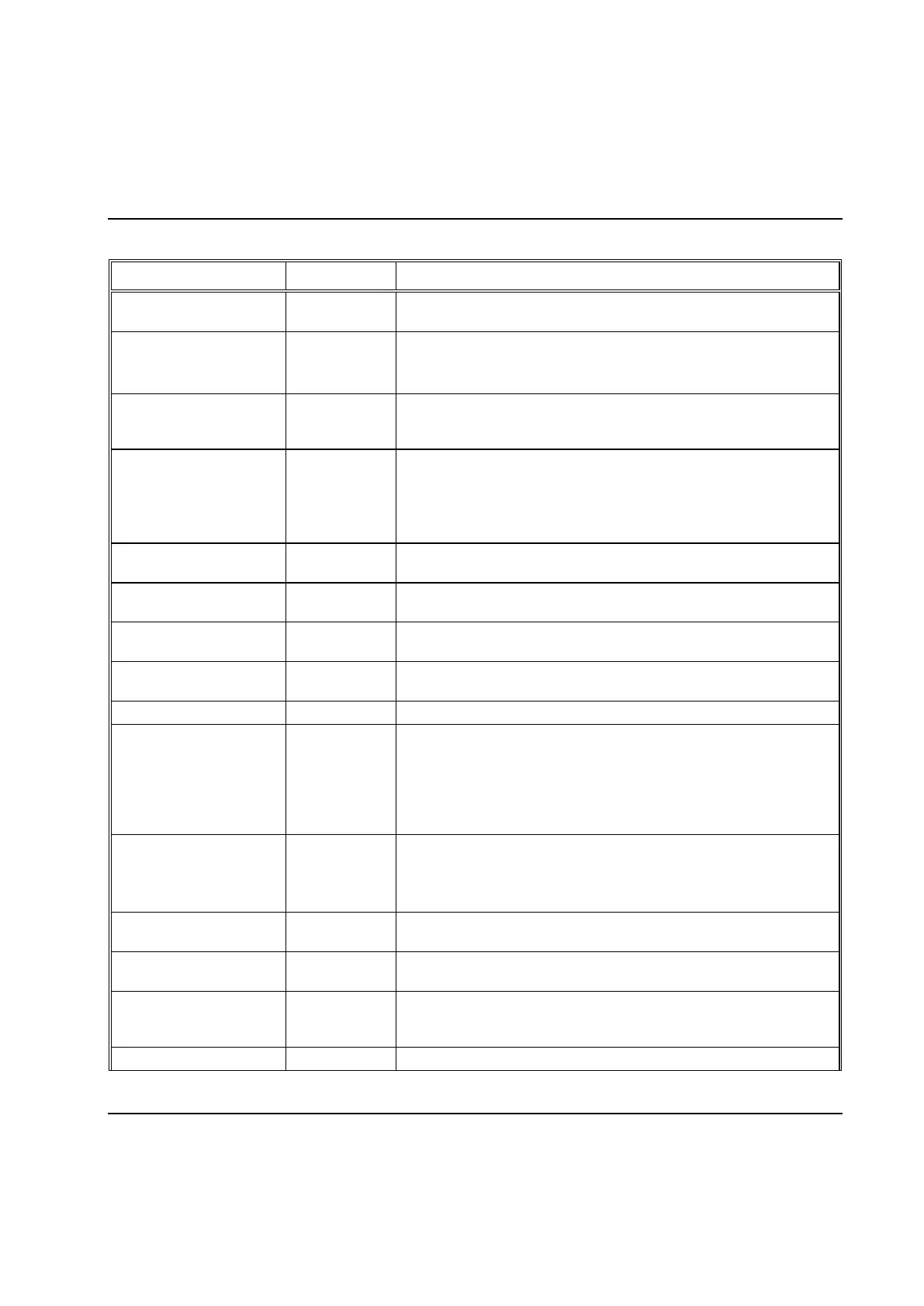

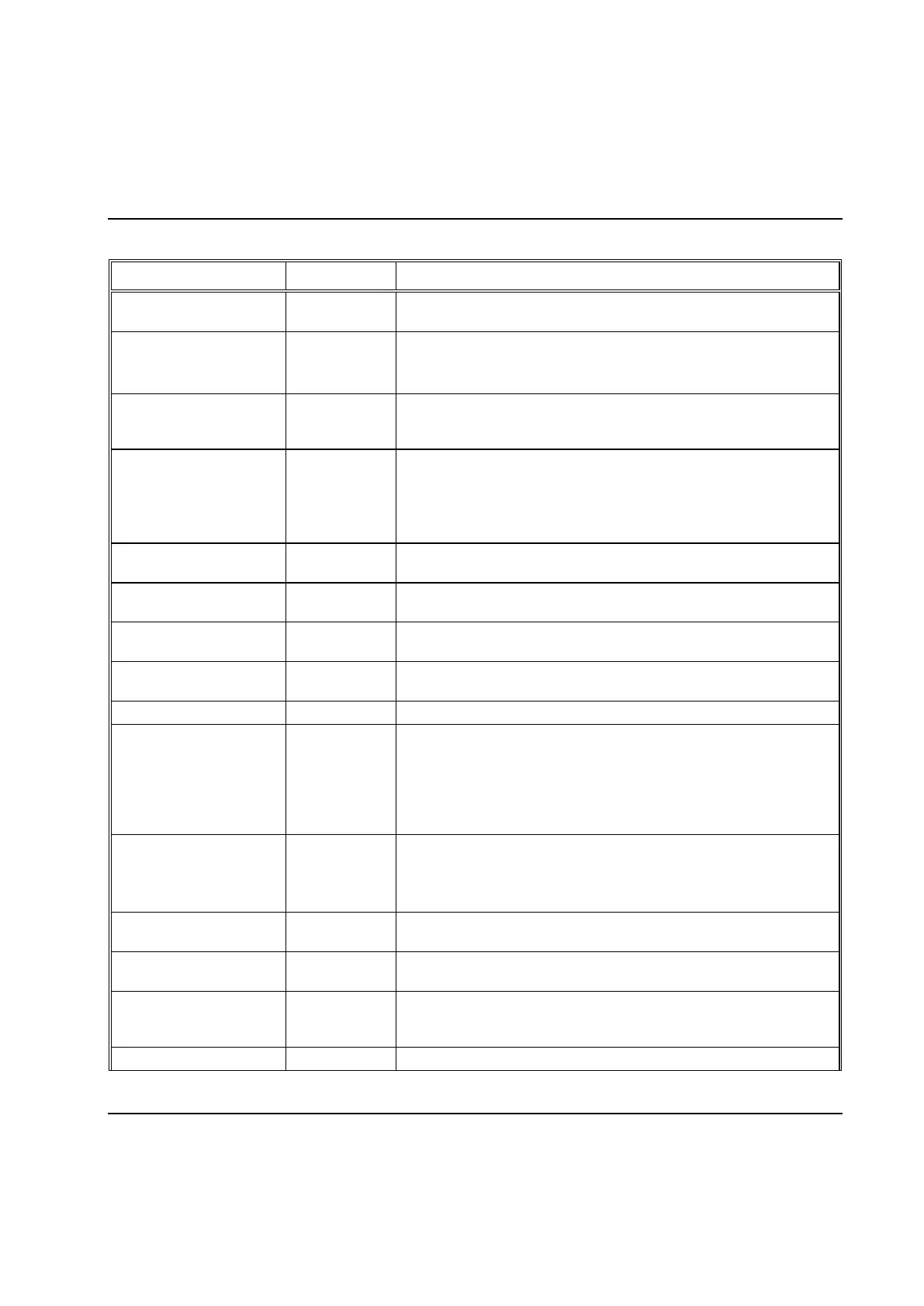

Outputs used for controlling the station:

Set to number of mode to use in next cycle. Sampled on the positive

edge of START.

Reset servo errors on a positive edge. Should only be set True if the

station is idle.

Note! All servos connected to the station are reset.

Starts cycle. A positive edge will start the first step in the cycle. This

signal is ignored if the station is not idle, or if STEPSTOP,

EMERGSTOP or MACHINESTOP is True.

Loosen cycle. When set to True mode 50 will be started and all

cycle data and trace data will be automaticly dropped. See detailed

description below.

Note that the cycle and trace data that is produced while loosening

is active is dropped and will not be stored in the system.

Step stop. Set to True to stop current step with status OK. Next

START will continue with next step in the cycle.

Emergency stop. Set to True to stop the cycle with status NOK.

Next START will start cycle from beginning.

Machine stop. Set to True to stop the cycle with status NOK. Next

positive edge on START will start a new cycle.

Start monitoring. Set to True to start monitoring of the spindles. This

signal is ignored if the station is not idle.

End monitoring. Set to True to end monitoring of the spindles.

Data hold. Set to True, before starting a cycle, to hold the

transmission of cycle data. The data is released when the input is

set to False if the station is idle (status < 4) and DATADROP is

False.

Note that the cycle data that is produced while hold is active will

contain only one station header, the one produced by the first start.

Data drop. If True when a cycle data is to be reported then the data

is dropped, without any distribution.

Cycle data is normally reported when the cycle ends but if

HOLDDATA is active it is reported when DATAHOLD is set to False.

Trace drop. If True when the cycle end the traces will not be

distributed to any device.

Set to a code 1-10 to generate an event. The code used will be

displayed together with the event.

Control data used for the PLC - Run PLC step used in the tightening

program. Defines which control function the step should execute.

See the step description for valid values.

Control data for the PLC - Run PLC step. Used as target value.

Loading...

Loading...