28

AL-KOCHASSIS

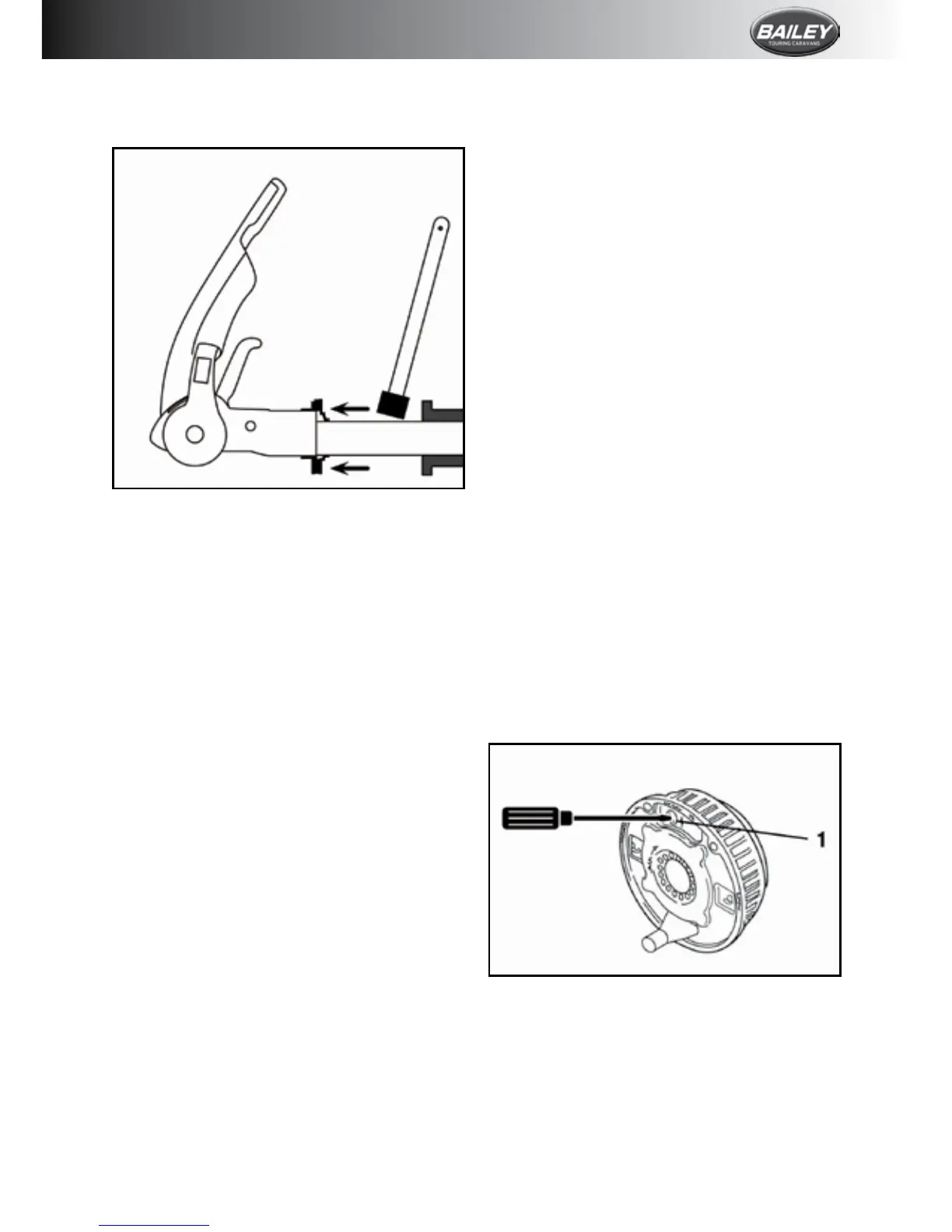

b.Lubricate the draw-shaft sleeve via the

greasenipples.Inaddition,pushthegaiter

forward and grease (DIN 51 825 KTA 3K)

theexposedpartoftheshaft(Fig,7).

FIG.7.

c.Visit a specialist workshop to have the

ballholdingareacheckedfor damageand

the locking mechanism for function. If

necessary,changethetowball.

Storing

To reduce the possibility of contamination

of component parts of the AKS 3004 the

stabilisinghandleshouldbeclosed.

Towing Ball

The automobile towing ball should measure

50mm maximum and 49mm minimum

diameter (DIN 74058). If the ball is below

49mm diameter it should be replaced

immediately.

Overrunning Device

The device housing is packed with grease

on assembly, but will require periodic

maintenance to ensure smooth operation of

thebrakingsystem.

i. Re-greasetheshaftbearingsviathegrease

nipples provided at 3,000 mile intervals,

andbeforestorage.

ii.Ensurecorrectfunctioningofallpivotpins

andleversandoilregularly.

iii.Ensure correct functioning of handbrake

ratchetandoilregularly.

Jockey Wheel

Lubricatewheelandscrewthreadperiodically

withgrease.

Brake Linkage

All moving parts should be lubricated

periodically to ensure their satisfactory

operation.

Corner Steadies

Thescrewandpivotpinsshouldbelubricated

periodically to ensure their satisfactory

operation.

Braking System Adjustment

(At 500 miles, then every 3,000 miles or 1

year)

i.Ensurethetowingshaftwithcouplingheads

ispulledfullyforward.

ii. Release the handbrake to the fully off

position.Ifthehandbrakewillnotgodown

thewholewaybecauseofthefairingorany

otherobstruction;thenthefairingmustbe

cut away and/or the obstruction removed

toachievethisdesiredposition.Itwillnot

be possible to set up the braking system

properlywhenthehandbrakeisnotinthe

fullyoffposition(g.8).

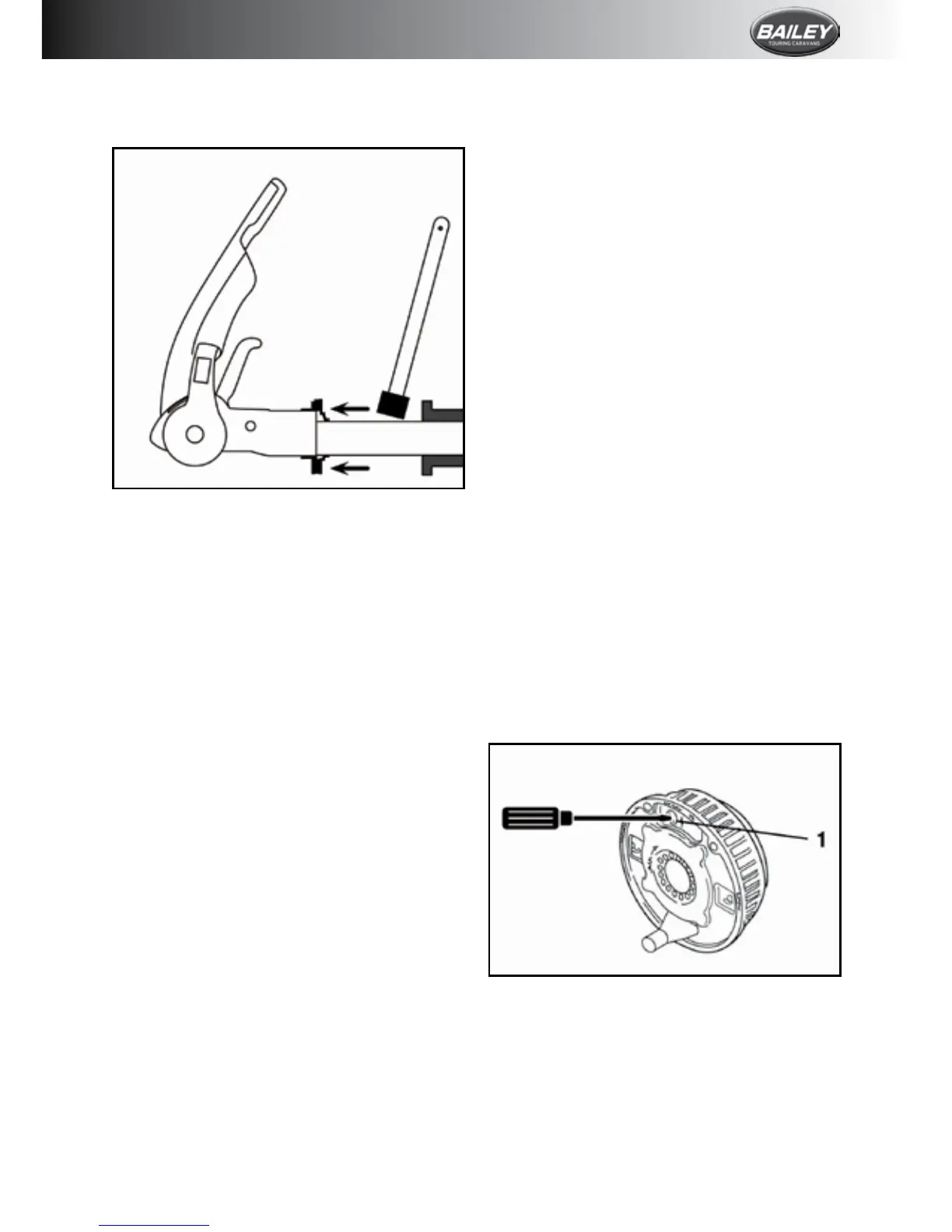

iii.Jackuponesideofthecaravan(seeJack

OperationInstructions).

iv. Remove the inner plastic bung from the

backplate to expose the “star-wheel”

adjusteraccess(FIG..8).

Loading...

Loading...