Operating Instructions ACU

The output of the first PT1 element is connected to the input of the second PT1 element which

contains the thermal time constant of the motor. This output may be loaded at 100% permanently.

This corresponds to full thermal loading of the motor. Once 102% are reached, the inverter will shut

down and an error will be reported. Both outputs are linked to an adjustable Warning Threshold.

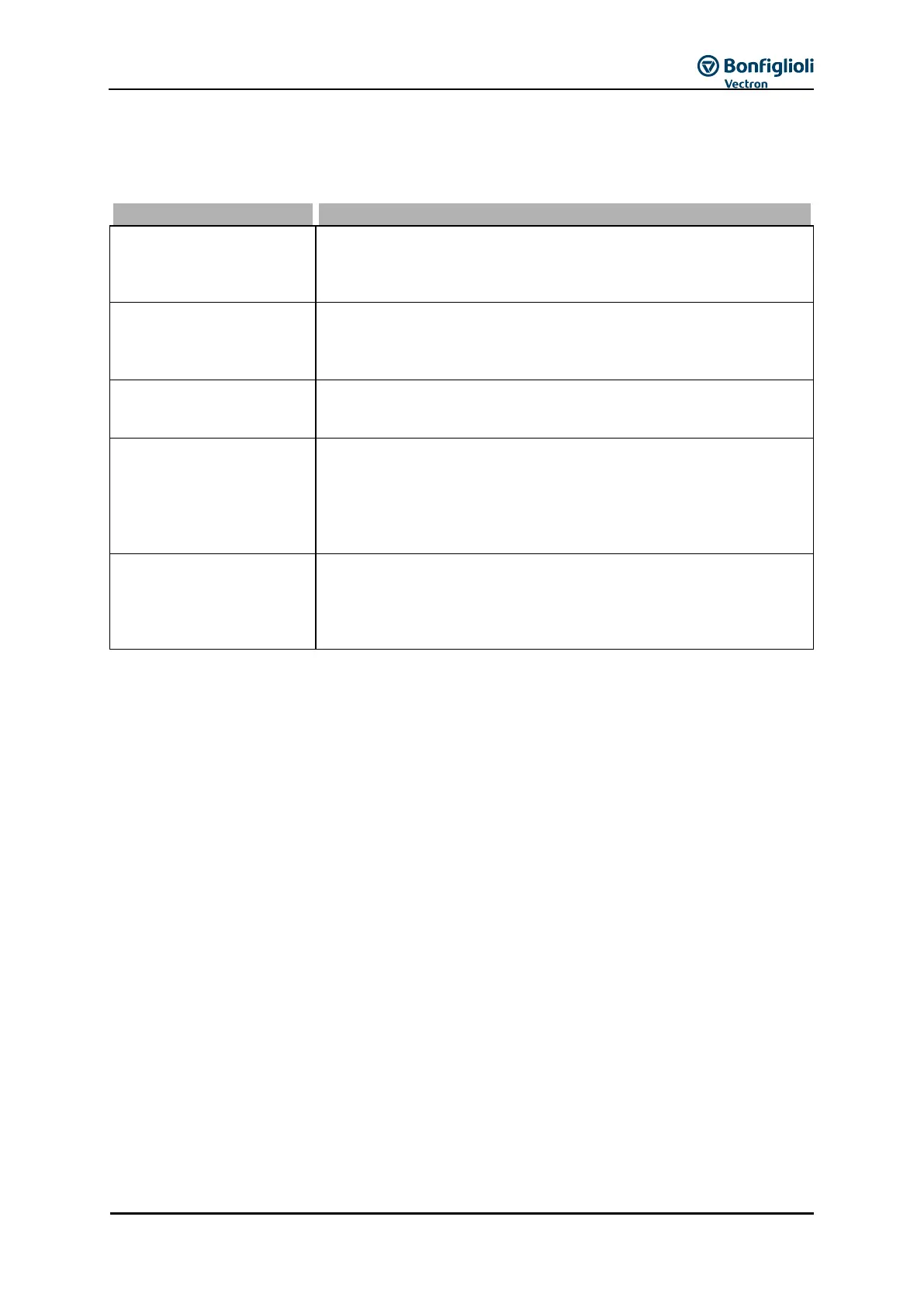

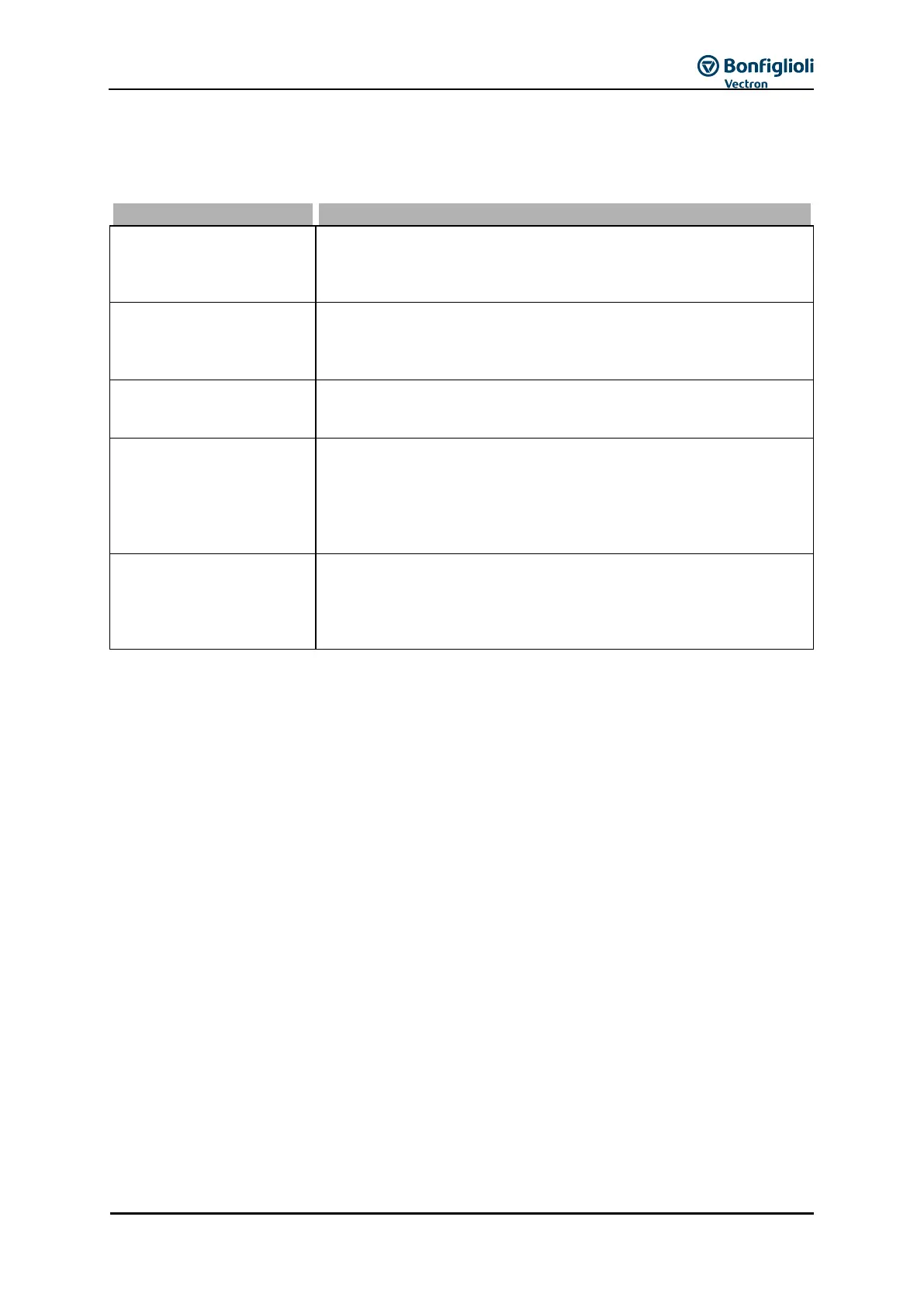

I²t, Single-Motor,

Err.Sw.-Off

The I²t load of the motor is monitored via the rated values from the

active data set. Once the fixed error threshold of 100%

Motor

(120%

Stator

) is exceeded, there will be an error shutdown “F0401” by the

active data set.

I2t,Multi-Motor

Op.,Warning

In each of the four data sets, the I²t load of the motors is monitored

based on the corresponding rated values. Once the set Warning Limit

I2t 615 is reached, a warning “A0200” will be triggered by the active

data set.

I2t,Single-Motor

Op.,Warning

The I²t load of the motor is monitored via the rated values from the

active data SE. Once the set Warning Limit I2t 615 is reached, a

warning “A0200” will be triggered by the active data set.

I²t,Multi-Motor

Op.,Warning and

Err.Sw.-Off

In each of the four data sets, the I²t load of the motors is monitored

based on the corresponding rated values. Once the set Warning Limit

I2t 615 is reached, a warning “A0200” will be triggered. Once the

fixed error threshold of 100%

Motor

(120%

Stator

) is exceeded, there will

be an error shutdown “F0401”. Both events will be triggered by the

active data set.

I²t,Single-Motor

Op.,Warning and

Err.Sw.-Off

The I²t load of the motor is monitored via the rated values from the

active data SE. Once the set Warning Limit I2t 615 is reached, a

warning “A0200” will be triggered. Once the fixed error threshold of

100%

Motor

(120%

Stator

) is exceeded, there will be an error shutdown

“F0401”. Both events will be triggered by the active data set.

The thermal time constant for the motor is in the range between a couple of minutes and several

hours. This motor-specific parameter is set via Thermal time constant motor 608.

The thermal time constant of the stator is much smaller. To protect the stator winding, additional

monitoring is required and defined via the Thermal time constant stator 609. For the time constant

values, refer to the relevant motor datasheets. If time constants are estimated, optimum motor

protection cannot be guaranteed.

Loading...

Loading...