Operating Instructions ACU

18.3 Technology controller

The technology controller, the behavior of which corresponds to a PID controller, is available as an

additional function in configuration 111, 211, 411, 511 and 611. The connection of reference and

actual value of the application with the functions of the frequency inverter enables process control

without further components. In this way, applications such as pressure, volume flow or speed

control can be implemented easily. The configuration of the reference percentage source and the

assignment of the actual percentage source are to be considered.

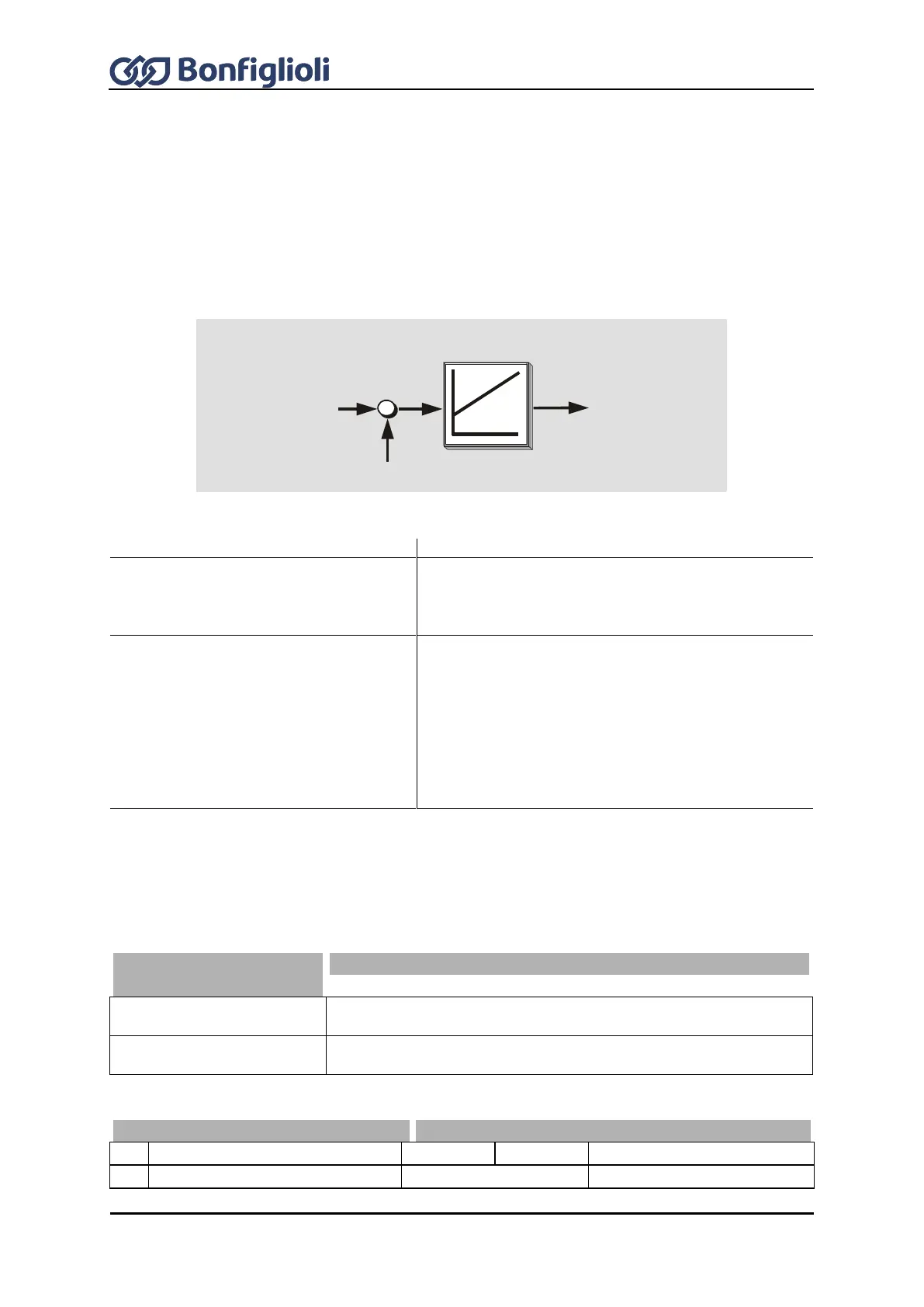

Structural image: Technology controller

-

Technology controller

Reference

percentage source 476

Actual percentage source 478

Actual values:

Actual percentage value 230

Reference percentage value 229

Note the chapters indicated in the table:

Reference Percentage Source 476

Displays the current controller setpoint:

Reference Percentage Value 229

Actual Percentage Source 478 is:

- Analog signal at multifunction input:

- Frequency signal at digital input:

Displays the current actual controller

value:

Actual Percentage Value 230

For the reference value, the technology controller also demands the assignment of an analog

application figure with parameter Actual Percentage Source 478. The difference between reference

and actual value is used by the technology controller to control the drive system. The measured

actual value is mapped via a signal converter onto the input signal of the reference percentage

source.

Actual Percentage Source

478

The analog signal on multifunction input 1 in analog Operation Mode

452.

Repetition frequency

input (F3)

The frequency signal on the digital input corresponding to the

selected Operation Mode 496.

Technology Controller Release

Loading...

Loading...