87

(3)CYLINDER BLOCK, CRANKSHAFT,

PISTONS AND OIL PAN

1.Pistons, Piston Rings and Piston Pins

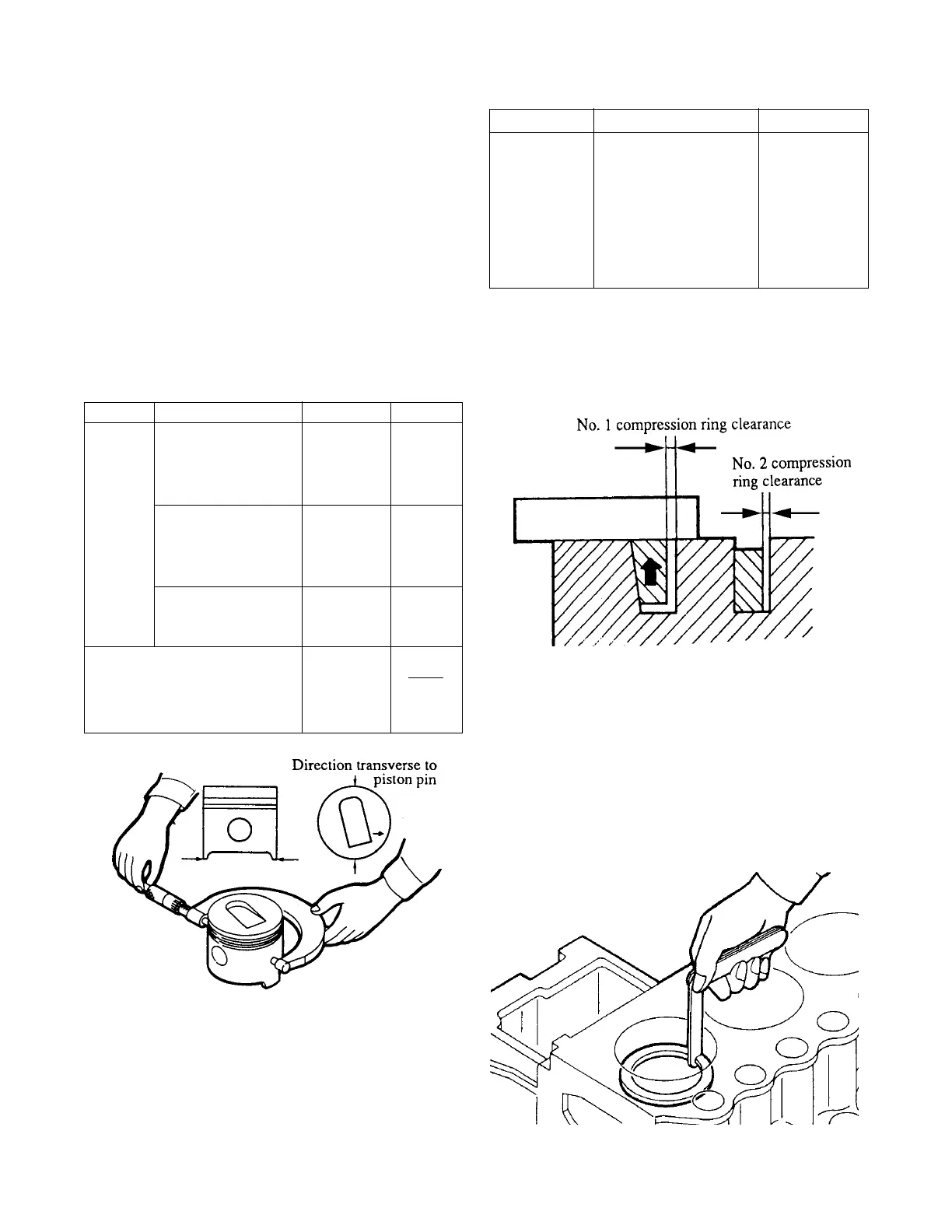

(1)Diameter of piston

Measure the diameter of the piston at its skirt

in a direction transverse to the piston pin with

a micrometer as shown in the illustration. If

the diameter exceeds the limit, replace the

piston. Select a new piston so that the differ-

ence between average weight of all pistons in

one engine does not exceed the standard.

Unit:mm(in.)

Item Nominal size Standard Limit

77.93 to

Standard 78.00 77.95 77.80

(3.0709) (3.0681 to (3.0630)

3.0689)

0.25 78.18to

Diameter (0.0098) 78.25 78.20 78.05

of piston oversize (3.0807) (3.0779to (3.0728)

3.0787)

0.50 78.43to

(0.0197) 78.50 78.45 78.30

oversize (3.0905) (3.0878to (3.0827)

Maximum permissible

difference between average 5(0.18)

weight of all pistons in one

engine, g(oz)

Unit:mm(in.)

Item Standard Limit

No.1 comp- 0.06 to 0.10 0.30(0.0118)

ression ring (0.0024 to 0.0039)

No.2 comp- 0.05 to 0.09 0.20(0.0079)

ression ring (0.0020 to 0.0035)

Oil ring 0.03 to 0.07 0.20(0.0079)

(0.0012 to 0.0028)

(b)If the clearance still exceeds the limit

after new piston rings have been

installed, replace the piston.

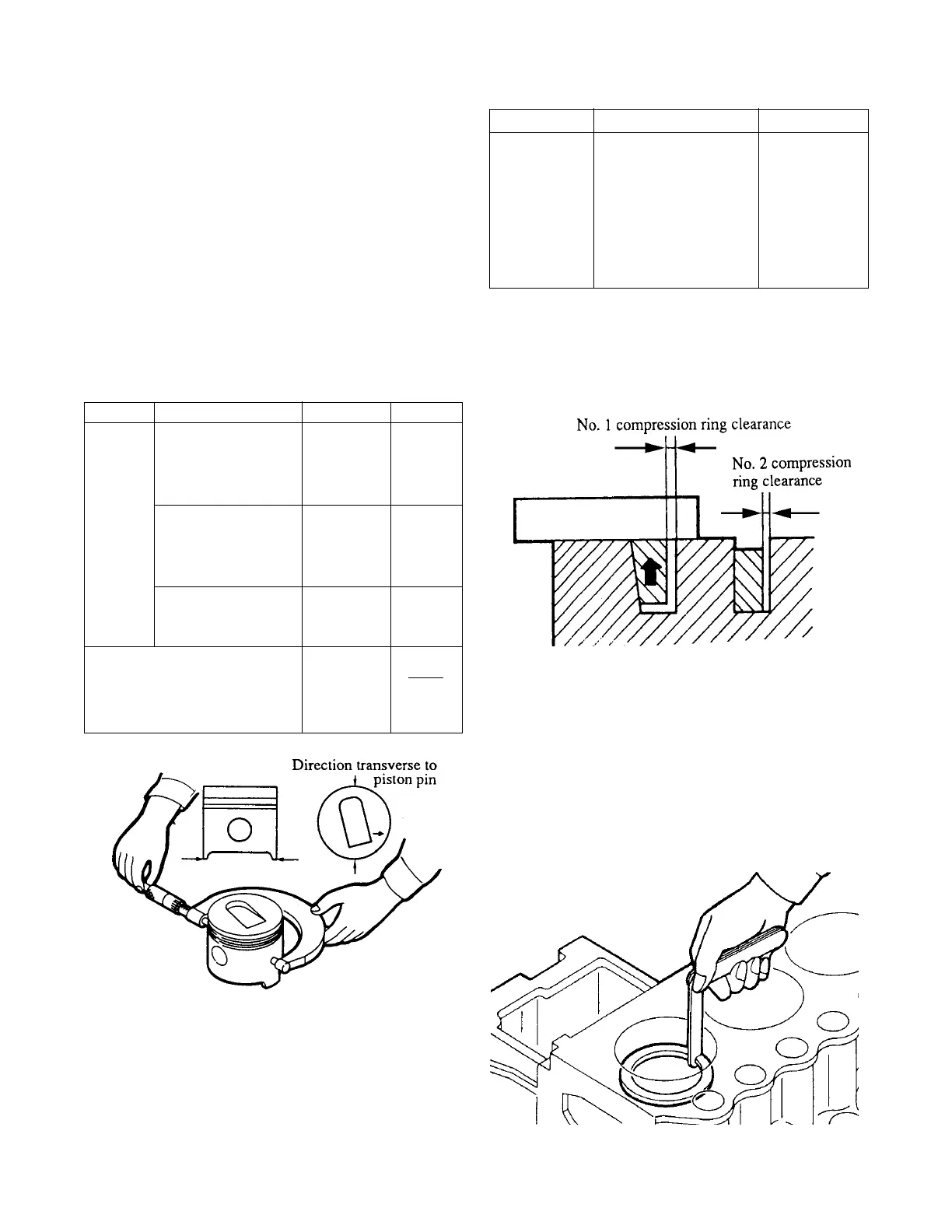

(3)Clearance between ends of piston ring

Put the piston ring in a gauge or in the bore in

a new cylinder block and measure the clear-

ance between the ends of the ring with a

feeler gauge as shown in the illustration. If the

clearance exceeds the limit, replace all the

rings.

(2)Clearance between piston ring and groove

(a)Measure the clearance between the

groove and piston with a straight edge

and a feeler gauge as shown in the

illustration. If the clearance exceeds the

limit, replace the ring.

Loading...

Loading...