4.2.5 29-5* Flow Conrmation

The ow conrmation feature is designed for applications

where there is a need for the motor/pump to run while

waiting for an external event. The ow conrmation

monitor expects to get a digital input from a sensor on a

gate valve, ow switch, or a similar external device

indicating that the device is in the open position and ow

is possible. In 29-50 Validation Time, a user denes how

long the VLT

®

AQUA Drive FC 202 waits for the digital

input signal from the external device to

conrm the ow.

After the ow is conrmed, the adjustable frequency drive

checks the signal again after the ow verication time and

then runs normally. The LCP status reads "Verifying ow"

while the ow monitor is active.

The adjustable frequency drive trips with the alarm Flow

Not

Conrmed, if the expected digital input signal becomes

inactive before either the ow validation time or the ow

verication time expires.

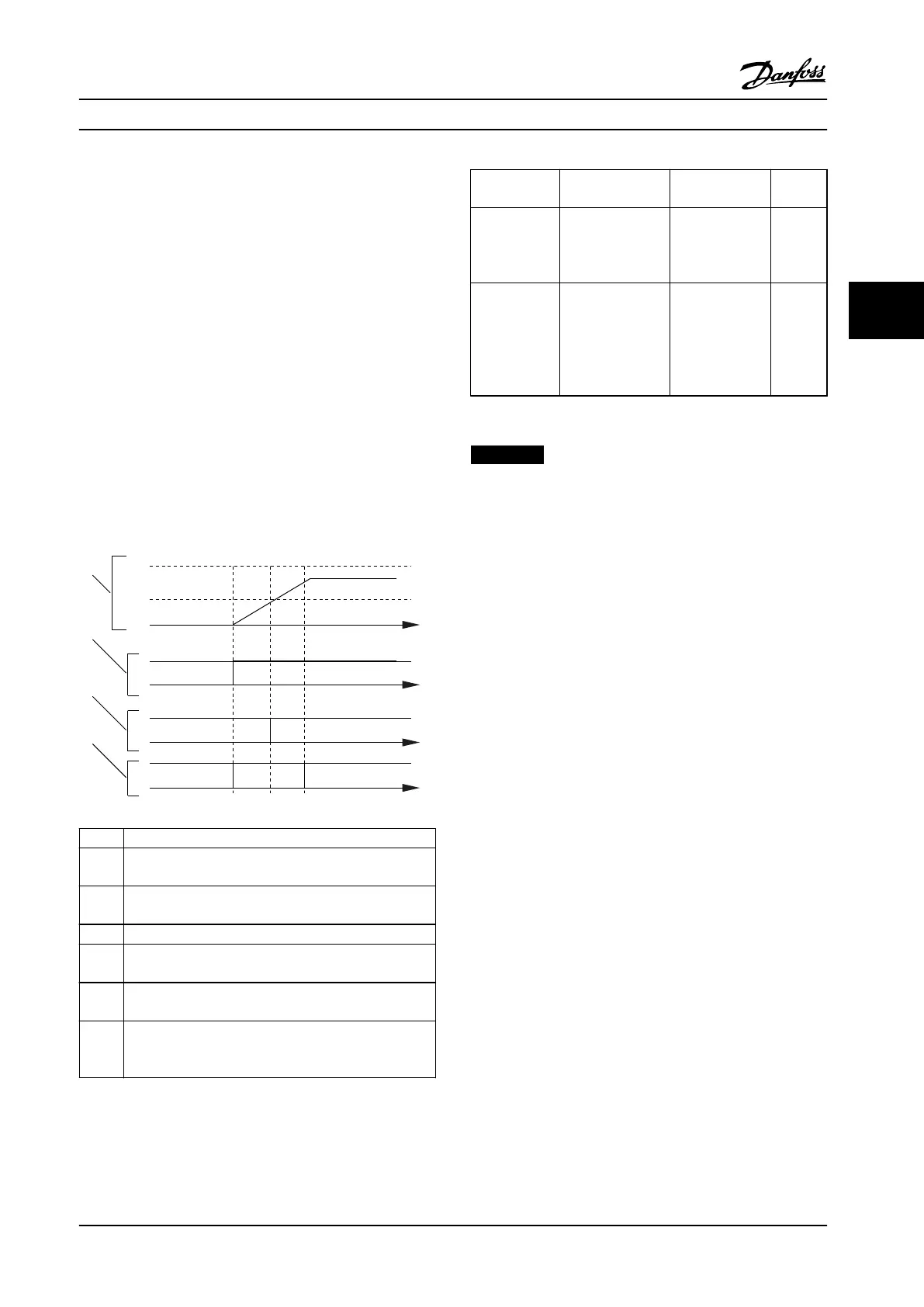

130BD766.10

N

MAX

N

MIN

0

0

1

1

0

1

0

1

2

3

4

t0 <t1 t2

T

T

T

T

1 Speed curve

2 Start command (for example, terminal 18)

3 Digital signal from an external device that conrms that

the ow is possible.

4 Flow verication

t

0

Start command issued (for example, terminal 18 is set

active)

t

1

Digital signal from an external device becomes active

before 29-50 Validation Time expires.

t

2

When 29-51 Verication Time passes, the adjustable

frequency drive checks the signal from the external

device again and then runs normally.

Figure 4.3 Flow Conrmation

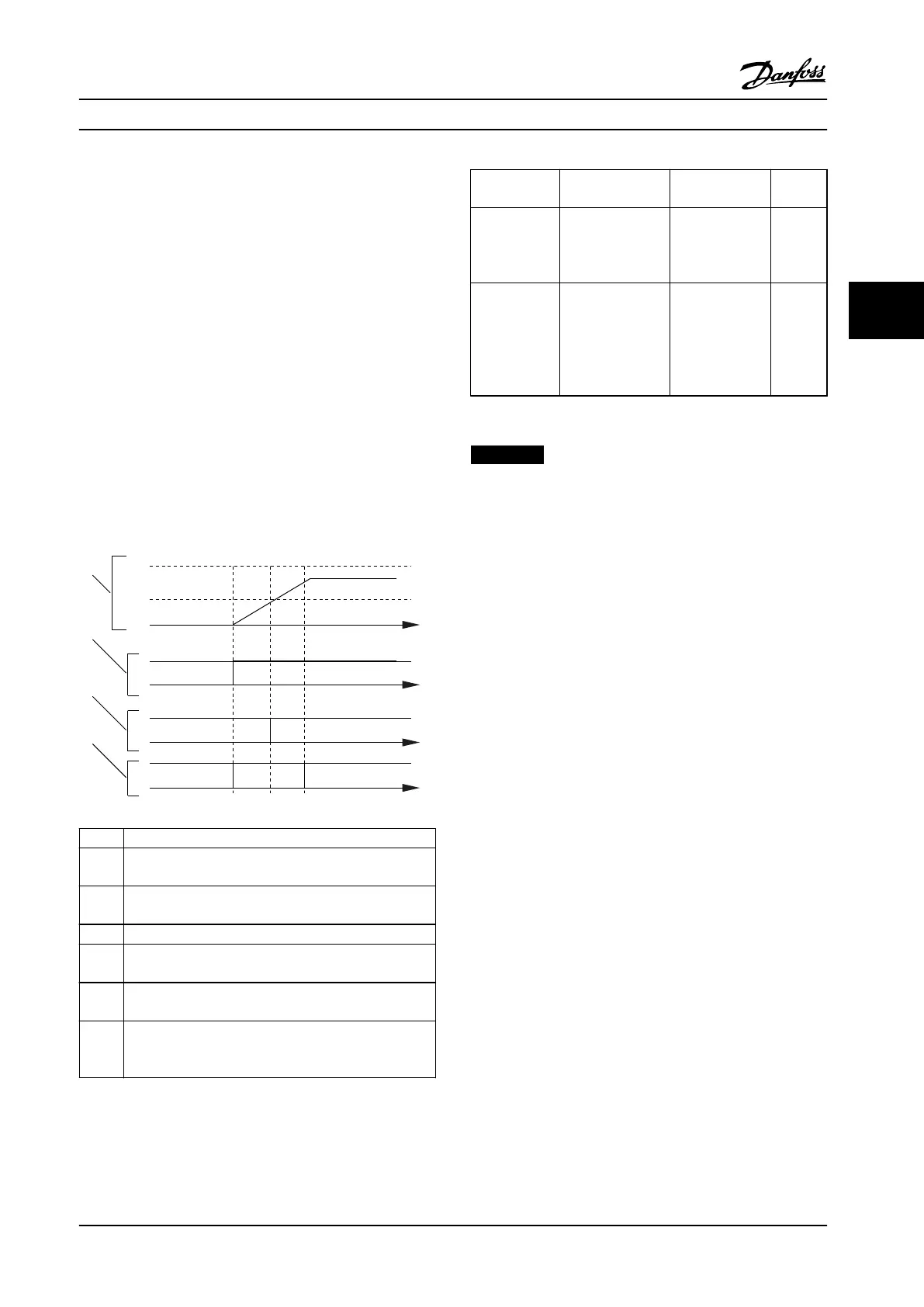

Parameter and

Name

Description Settings Unit

29-50 Validatio

n Time

The digital input

must be active

during the

validation time.

0.1–999.0

(*size dependent)

s

29-51 Veri-

cation Time

Flow will be

conrmed if, at the

end of the veri-

cation time, the

digital input is still

active.

0.1–255.0

(*15)

s

Table 4.2 Flow Conrmation Parameters

NOTICE!

The parameters are only visible on the LCP when a

digital input is congured as ow conrmation.

4.2.6 Advanced Minimum Speed

Monitoring for Submersible Pumps

Some pumps are very sensitive to operating at low speed.

Typical reasons for this are insucient cooling or

lubrication at low speed.

Under overload conditions, the adjustable frequency drive

protects itself using its integral protection features, which

include lowering the speed. For example, the current limit

controller can lower the speed. This means that, in some

cases, the speed may go lower than the speed specied in

4-11 Motor Speed Low Limit [RPM] and 4-12 Motor Speed

Low Limit [Hz].

The advanced minimum-speed monitoring feature trips the

adjustable frequency drive if the speed drops below a

certain value. If the pump motor of the pump does not

reach the speed

specied in 1-86 Trip Speed Low [RPM]

within the time specied in 1-79 Pump Start Max Time to

Trip (ramping up takes too long), the adjustable frequency

drive trips. Timers for 1-71 Start Delay and 1-79 Pump Start

Max Time to Trip start at the same time when the start

command is issued. For instance, this means that if the

value in 1-71 Start Delay is more than or equal to the value

in 1-79 Pump Start Max Time to Trip, the adjustable

frequency drive never starts.

Application Examples

Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 103

4 4

Loading...

Loading...