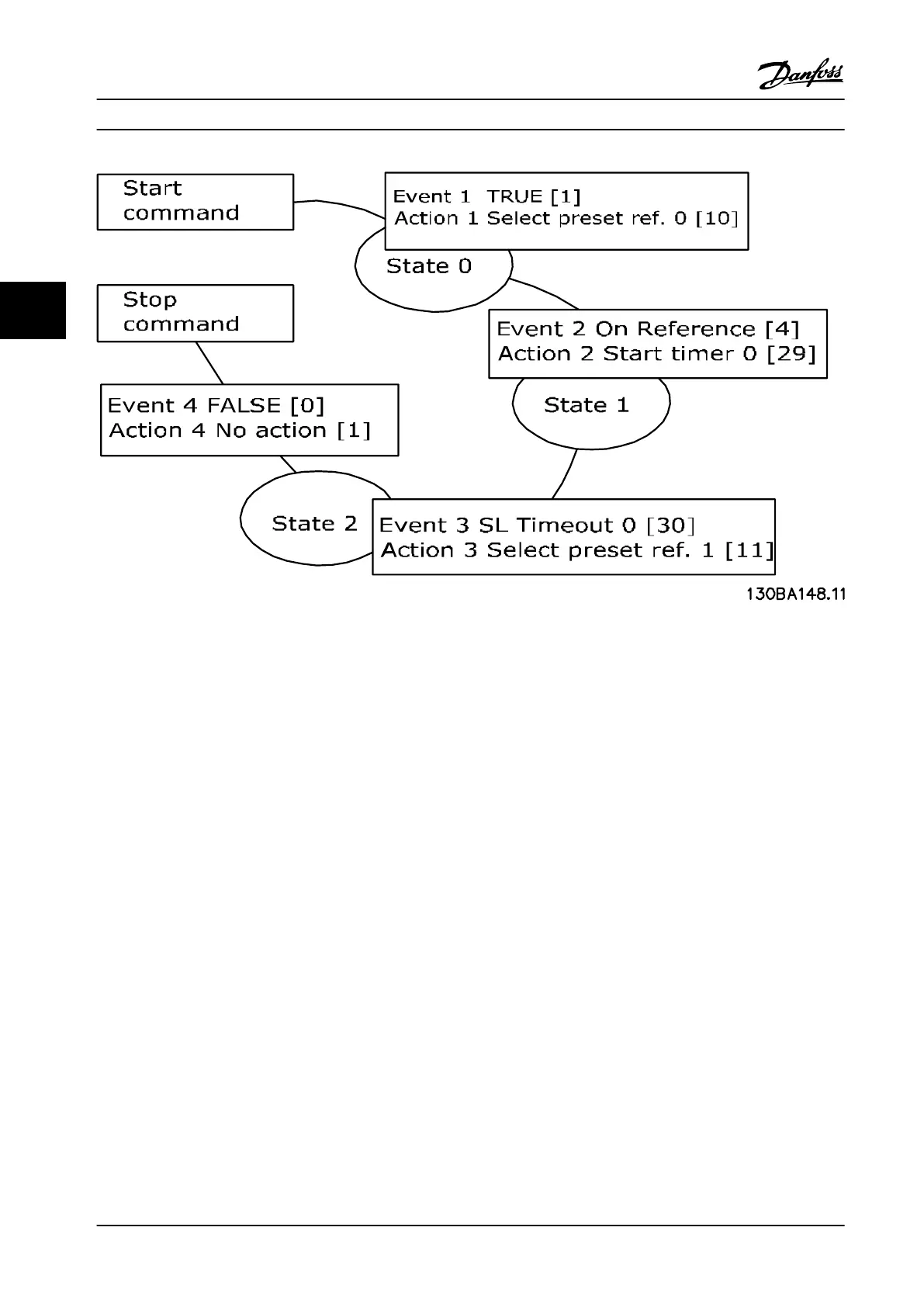

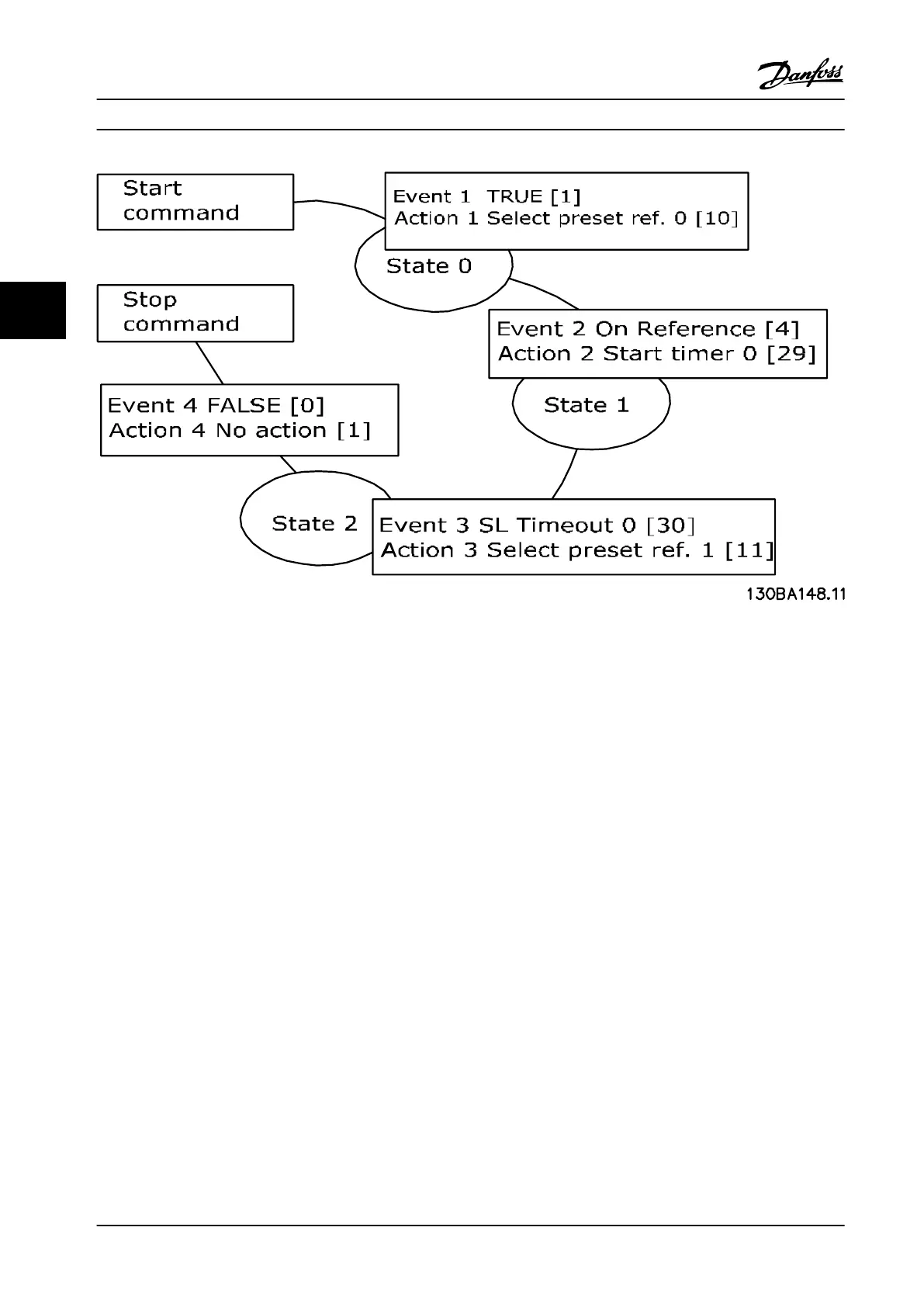

Figure 4.6 SLC Application Example

4.3.1

Submersible Pump Application

The system consists of a submersible pump controlled by a

Danfoss VLT

®

AQUA Drive and a pressure transmitter. The

transmitter gives a 4-20 mA feedback signal to the

adjustable frequency drive, which keeps a constant

pressure by controlling the speed of the pump. To design

an adjustable frequency drive for a submersible pump

application, there are a few important issues to consider.

Select the adjustable frequency drive according to motor

current.

1.

The motor is a so-called CAN motor with a

stainless steel can between the rotor and stator.

There is a larger and a more magnetic resistant

air-gap than on a normal motor, hence a weaker

eld, which results in the motors being designed

with a higher rated current than a normal motor

with similar rated power.

2. The pump contains thrust bearings that are

damaged when running below minimum speed,

which is normally 30 Hz.

3. The motor reactance is nonlinear in submersible

pump motors and, therefore, automatic motor

adaption (AMA) may not be possible. Normally,

submersible pumps are operated with long motor

cables that might eliminate the nonlinear motor

reactance and enable the adjustable frequency

drive to perform AMA. If AMA fails, the motor

data can be set from parameter group 1-3* Adv.

Motor Data (see the motor datasheet). Be aware

that, if AMA has succeeded, the adjustable

frequency drive will compensate for the voltage

drop in the long motor cables. This means that if

the advanced motor data are set manually, the

length of the motor cable must be considered to

optimize system performance.

4. It is important that the system be operated with

a minimum of wear and tear on the pump and

motor. A Danfoss sine-wave lter can lower the

motor insulation stress and increase lifetime

(check actual motor insulation and the adjustable

frequency drive dU/dt specication). Note that

most manufacturers of submersible pumps

require the use of output lters.

5. EMC performance can be dicult to achieve due

to the fact that the special pump cable, which is

able to withstand the wet conditions in the well

is normally non-shielded. A solution could be to

use a shielded cable above the well and x the

shield to the well pipe if it is made of steel. A

sine-wave lter also reduces the EMI from non-

shielded motor cables.

Application Examples

VLT

®

AQUA Drive FC 202

106 Danfoss A/S © 09/2014 All rights reserved. MG20N622

44

Loading...

Loading...