The adjustable frequency drive manages various motor

control principles such as U/f special motor mode and VVC

+

. Short-circuit behavior of the adjustable frequency drive

depends on the three current transducers in the motor

phases.

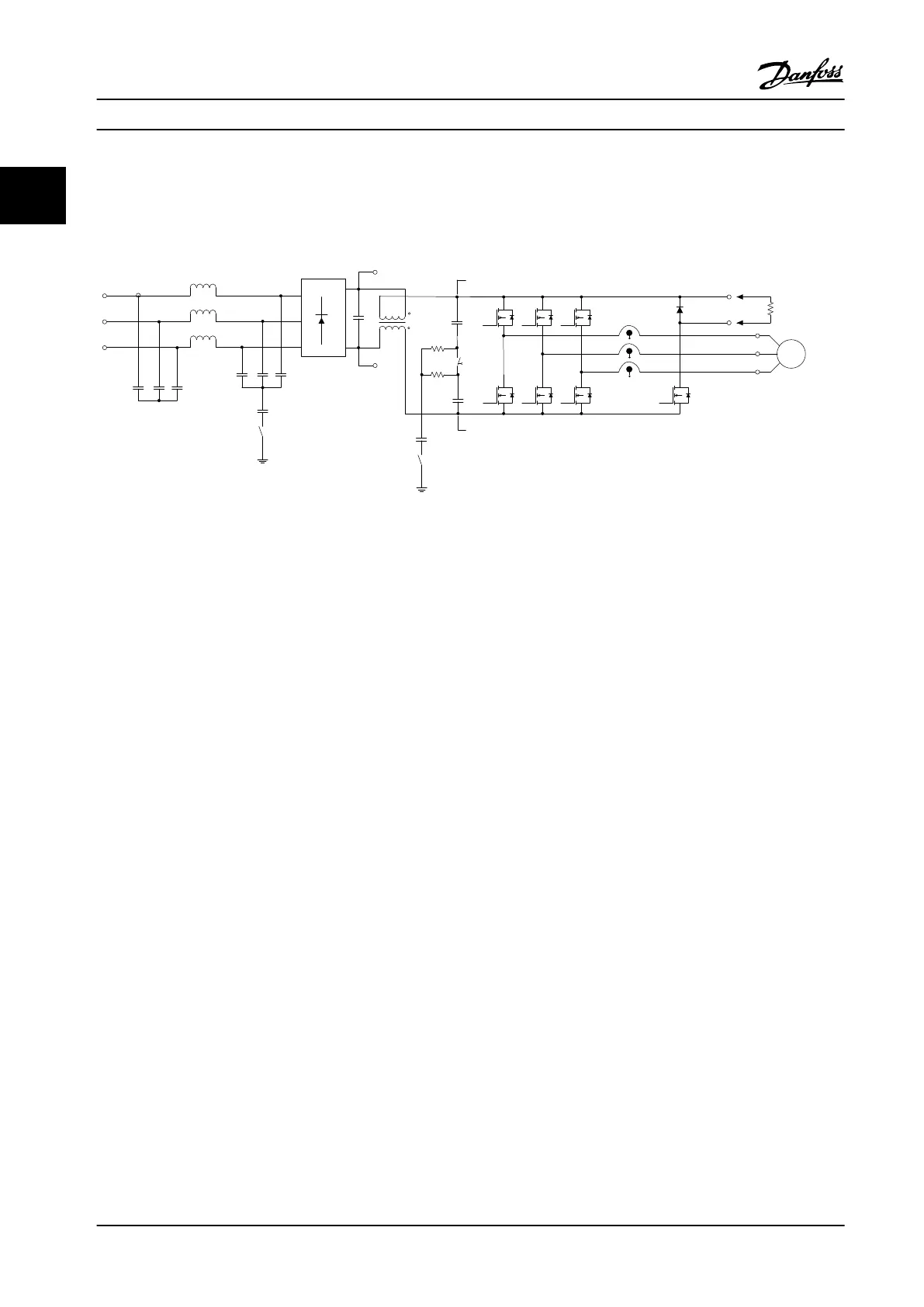

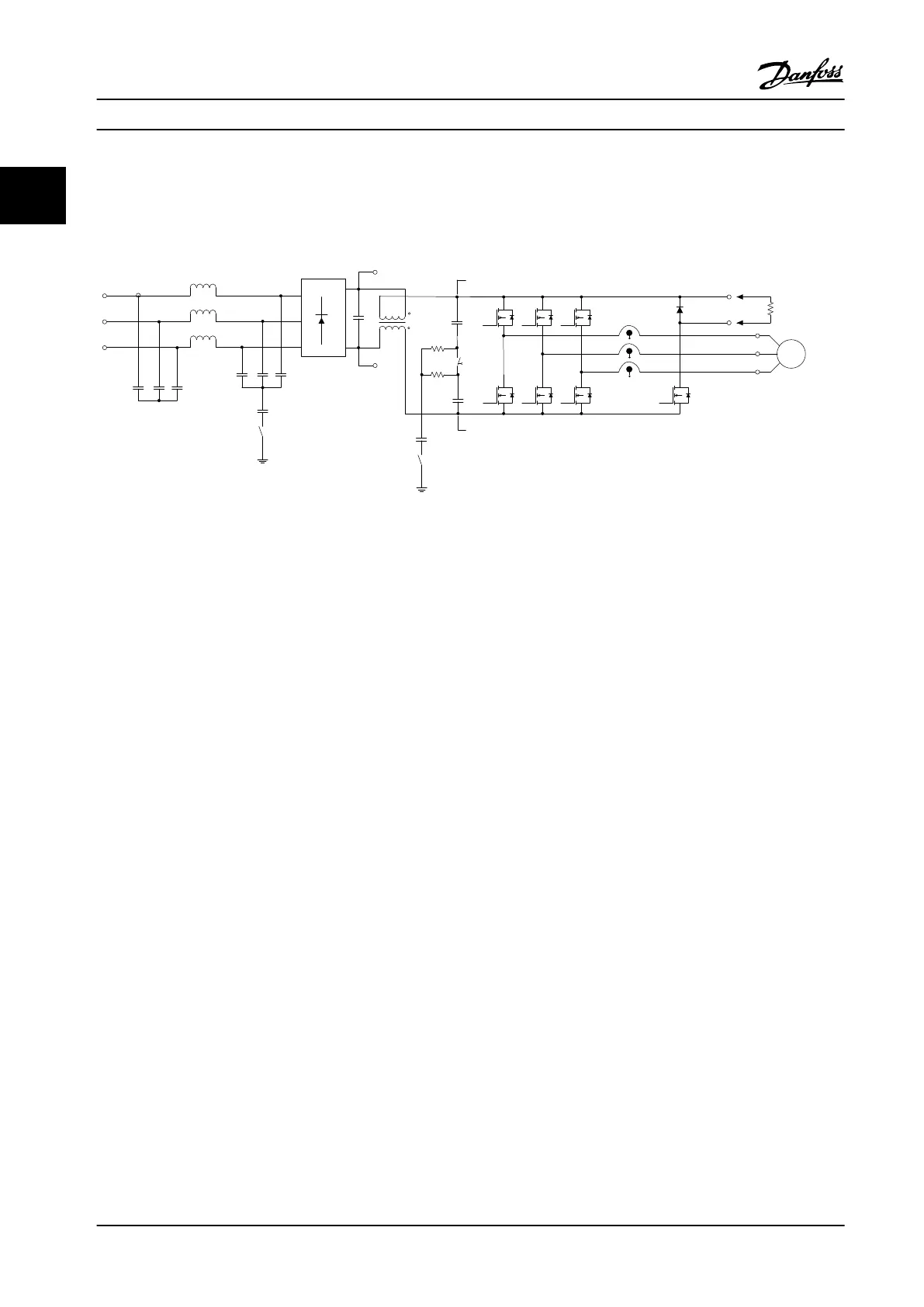

Inrush

R inr

Load sharing -

Load sharing +

LC Filter -

(5A)

LC Filter +

(5A)

Brake

Resistor

130BA193.14

M

L2 92

L1 91

L3 93

89(+)

88(-)

R+

82

R-

81

U 96

V 97

W 98

P 14-50 R Filter

Figure 2.10 Adjustable Frequency Drive Structure

2.3 Sequence of Operation

2.3.1 Rectier Section

When power is applied to the adjustable frequency drive, it

enters through the line power terminals (L1, L2, and L3)

and on to the disconnect and/or RFI lter option,

depending on the unit conguration.

2.3.2 Intermediate Section

Following the rectier section, voltage passes to the

intermediate section. A sine-wave lter circuit consisting of

the DC bus inductor and the DC bus capacitor bank

smoothes the rectied voltage.

The DC bus inductor provides series impedance to

changing current. This aids the ltering process while

reducing harmonic distortion to the input AC current

waveform normally inherent in rectier circuits.

2.3.3

Inverter Section

In the inverter section, once a run command and speed

reference are present, the IGBTs begin switching to create

the output waveform. This waveform, as generated by the

Danfoss VVC

+

PWM principle at the control card, provides

optimal performance and minimal losses in the motor.

2.3.4

Brake Option

For adjustable frequency drives equipped with the

dynamic brake option, a brake IGBT along with terminals

81(R-) and 82(R+) are included for connecting an external

brake resistor.

The function of the brake IGBT is to limit the voltage in the

intermediate circuit whenever the maximum voltage limit

is exceeded. It does this by switching the externally

mounted resistor across the DC bus to remove excess DC

voltage present on the bus capacitors.

External brake resistor placement has the advantages of

selecting the resistor based on application need,

dissipating the energy outside of the control panel, and

protecting the drive from overheating if the brake resistor

is overloaded.

The brake IGBT gate signal originates on the control card

and is delivered to the brake IGBT via the power card and

gate drive card. Additionally, the power and control cards

monitor the brake IGBT and brake resistor connection for

short circuits and overloads. For pre-fuse

specications,

refer to chapter 7.1 Electrical Data. See also

chapter 7.7 Fuses and Circuit Breakers.

Product Overview

VLT

®

AQUA Drive FC 202

20 Danfoss A/S © 09/2014 All rights reserved. MG20N622

22

Loading...

Loading...