2 Product Overview

2.1 Introduction

This chapter provides an overview of the adjustable

frequency drive’s primary assemblies and circuitry. It

describes the internal electrical and signal processing

functions. A description of the internal control structure is

also included.

Also described are automated and optional adjustable

frequency drive functions available for designing robust

operating systems with sophisticated control and status

reporting performance.

2.1.1

Product Dedication to Water and

Wastewater Applications

The VLT

®

AQUA Drive FC 202 is designed for water and

wastewater applications. The integrated SmartStart wizard

and the quick menu Water and Pumps guide the user

through the commissioning process. The range of standard

and optional features includes:

•

Cascade control

•

Dry-run detection

•

End of curve detection

•

Motor alternation

•

Deragging

•

Initial and

nal ramp

•

Check valve ramp

•

STO

•

Low-ow detection

•

Pre-lube

•

Flow conrmation

•

Pipe ll mode

•

Sleep mode

•

Real time clock

•

Password protection

•

Overload protection

•

Smart logic control

•

Minimum speed monitor

•

Free programmable texts for information,

warnings and alerts

2.1.2

Energy Savings

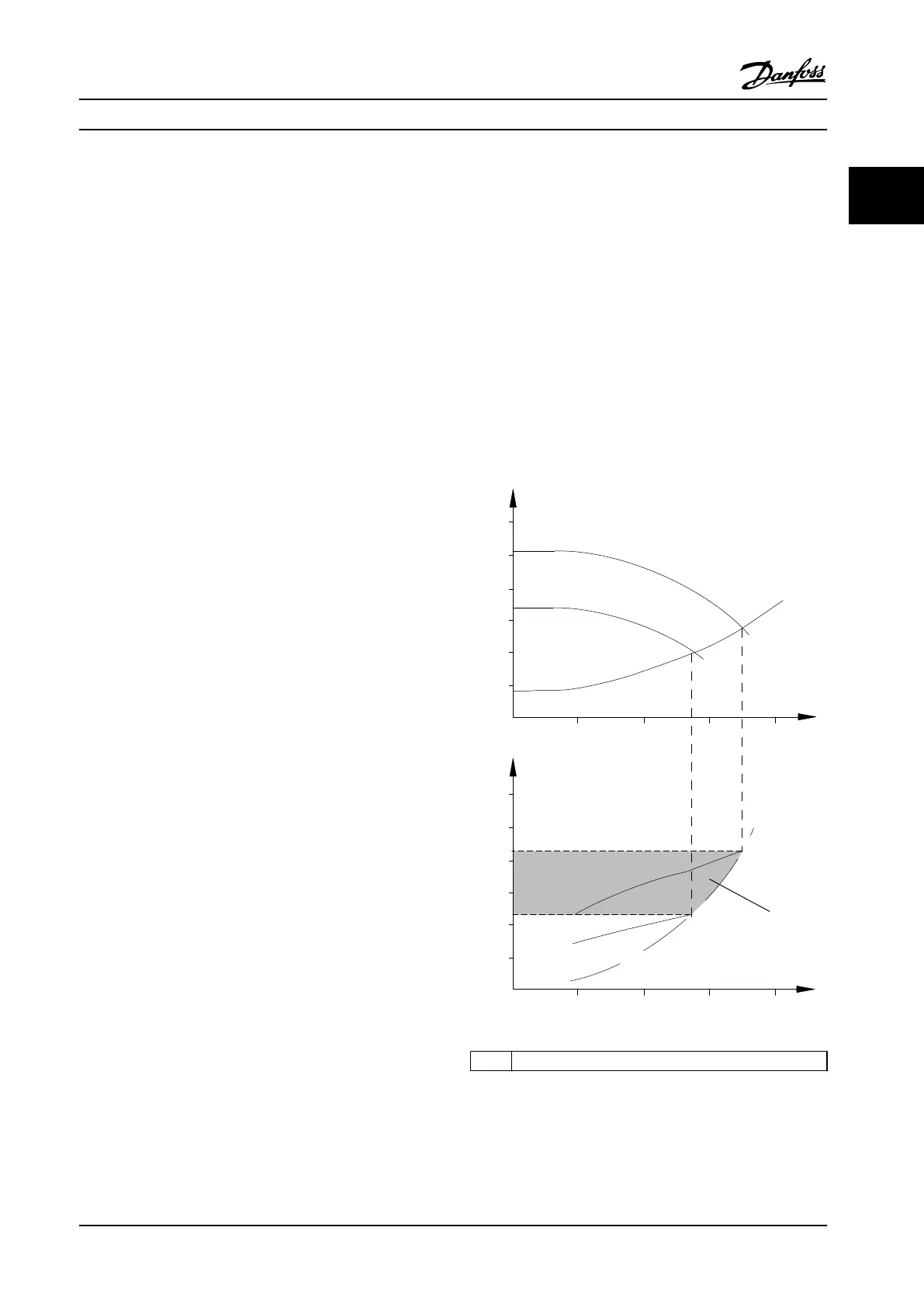

Compared to alternative control systems and technologies,

an adjustable frequency drive is the optimum energy

control system for controlling fan and pump systems.

By using an adjustable frequency drive to control the ow,

a pump speed reduction of 20% leads to energy savings of

about 50% in typical applications.

Figure 2.1 shows an example of the achievable energy

reduction.

130BD889.10

60

50

40

30

20

10

H

s

0 100 200 300 400

(mwg)

1350rpm

1650rpm

0

10

20

30

(kW)

40

50

60

200100 300

(m

3

/h)

(

m

3

/h)

400

1350rpm

1650rpm

P

shaft

1

1 Energy saving

Figure 2.1 Example: Energy Saving

Product Overview Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 15

2 2

Loading...

Loading...