3.4 Motor Integration

3.4.1 Motor Selection Considerations

The adjustable frequency drive can induce electrical stress

on a motor. Consider, therefore, the following eects on

the motor when matching motor with adjustable

frequency drive:

•

Insulation stress

•

Bearing stress

•

Thermal stress

3.4.2

Sine-wave and dU/dt Filters

Output lters provide benets to some motors to reduce

electrical stress and allow for longer cable length. Output

options include sine-wave lters (also called LC lters) and

dU/dt lters. The dU/dt lters reduce the sharp rise rate of

the pulse. Sine-wave lters smooth the voltage pulses to

convert them into a nearly sinusoidal output voltage. With

some adjustable frequency drives, sine-wave

lters comply

with EN 61800-3 RFI category C2 for non-shielded motor

cables, see chapter 3.7.5 Sine-wave Filters.

For more information on sine-wave and dU/dt lter

options, refer to chapter 3.7.5 Sine-wave Filters and

chapter 3.7.6 dU/dt Filters.

For more information on sine-wave and dU/dt lter

ordering numbers, refer to and chapter 6.2.9 dU/dt Filters.

3.4.3

Proper Motor Grounding

Proper grounding of the motor is imperative for personal

safety and to meet EMC electrical requirements for low

voltage equipment. Proper grounding is necessary for the

eective use of shielding and lters. Design details must

be veried for proper EMC implementation.

3.4.4

Motor Cables

Motor cable recommendations and specications are

provided in chapter 7.5 Cable Specications.

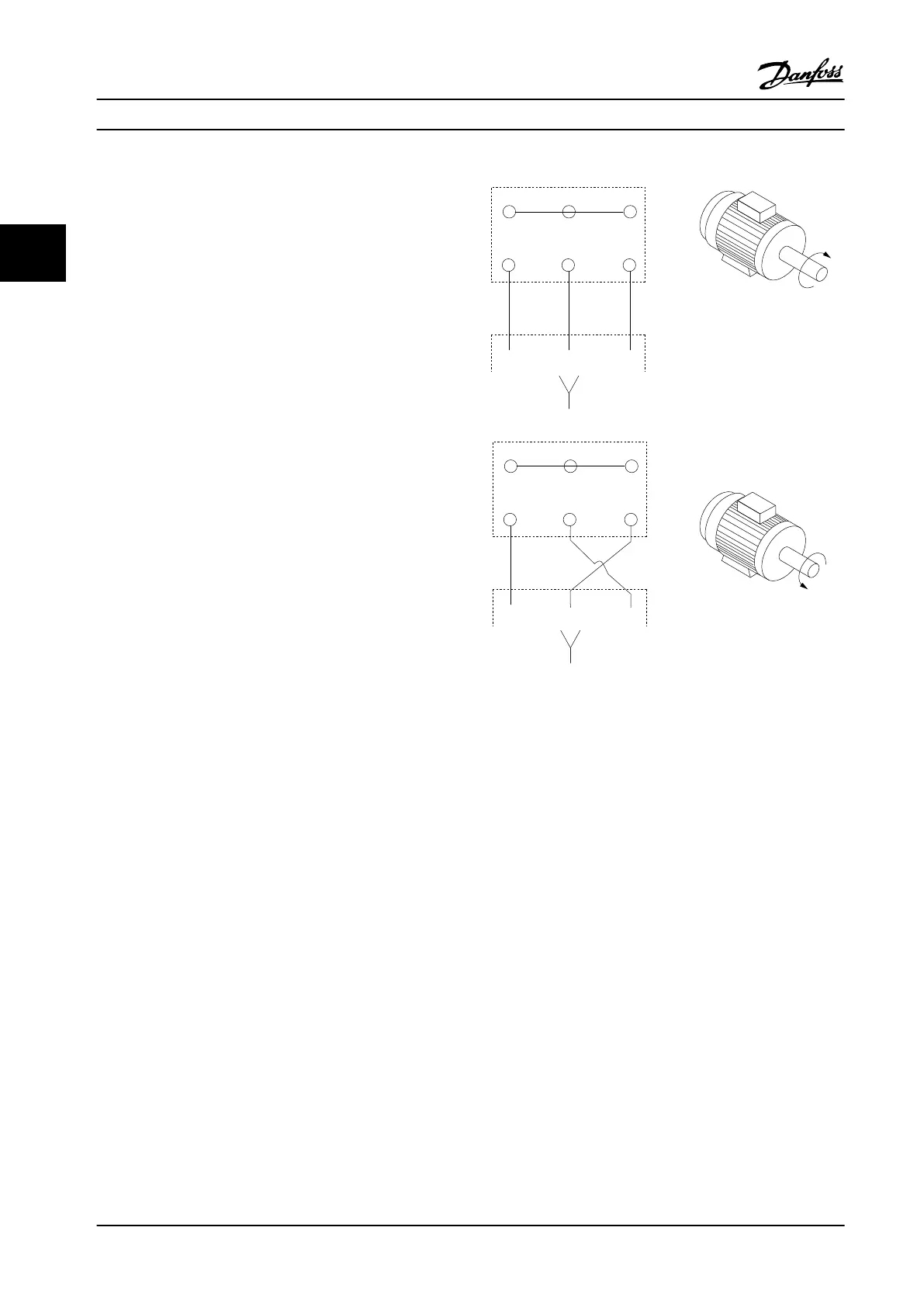

All types of three-phase asynchronous standard motors can

be used with an adjustable frequency drive unit. The

factory setting is for clockwise rotation with the adjustable

frequency drive output connected as follows:

175HA036.11

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

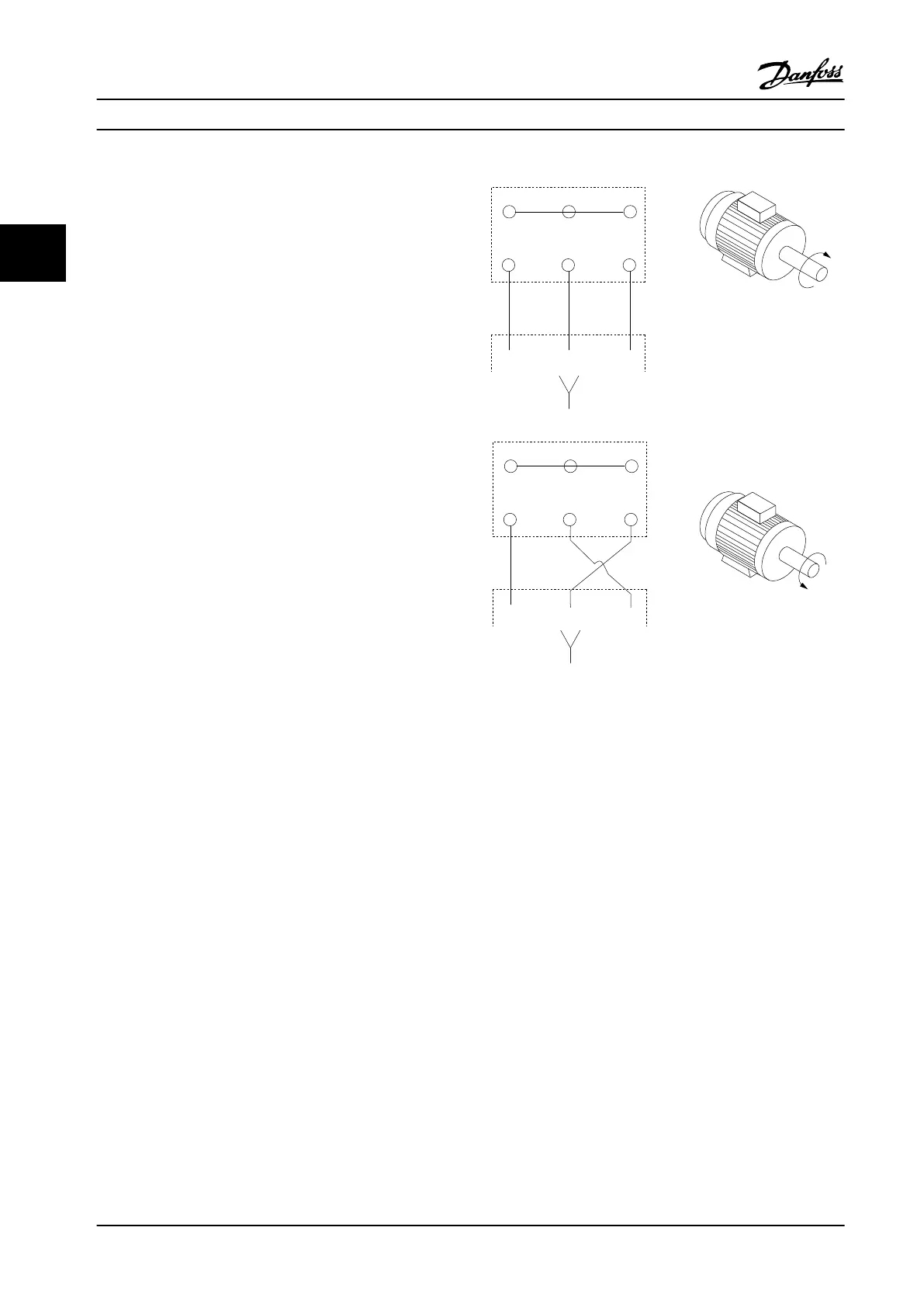

Figure 3.10 Terminal Connection for Clockwise and Counter-

clockwise Rotation

Change the direction of rotation by switching two phases

in the motor cable or by changing the setting of

4-10 Motor Speed Direction.

3.4.5

Motor Cable Shielding

Adjustable frequency drives generate steep-edged pulses

on their outputs. These pulses contain high-frequency

components (extending into the gigahertz range), which

cause undesirable radiation from the motor cable. Shielded

motor cables reduce this radiation.

The purposes of shielding are to:

•

Reduce the magnitude of radiated interference.

•

Improve the interference immunity of individual

devices.

The shield captures the high-frequency components and

conducts them back to the interference source, in this case

the adjustable frequency drive. Shielded motor cables also

provide immunity to interference from nearby external

sources.

System Integration

VLT

®

AQUA Drive FC 202

58 Danfoss A/S © 09/2014 All rights reserved. MG20N622

33

Loading...

Loading...