4.3.3 Pump Staging with Lead Pump

Alternation

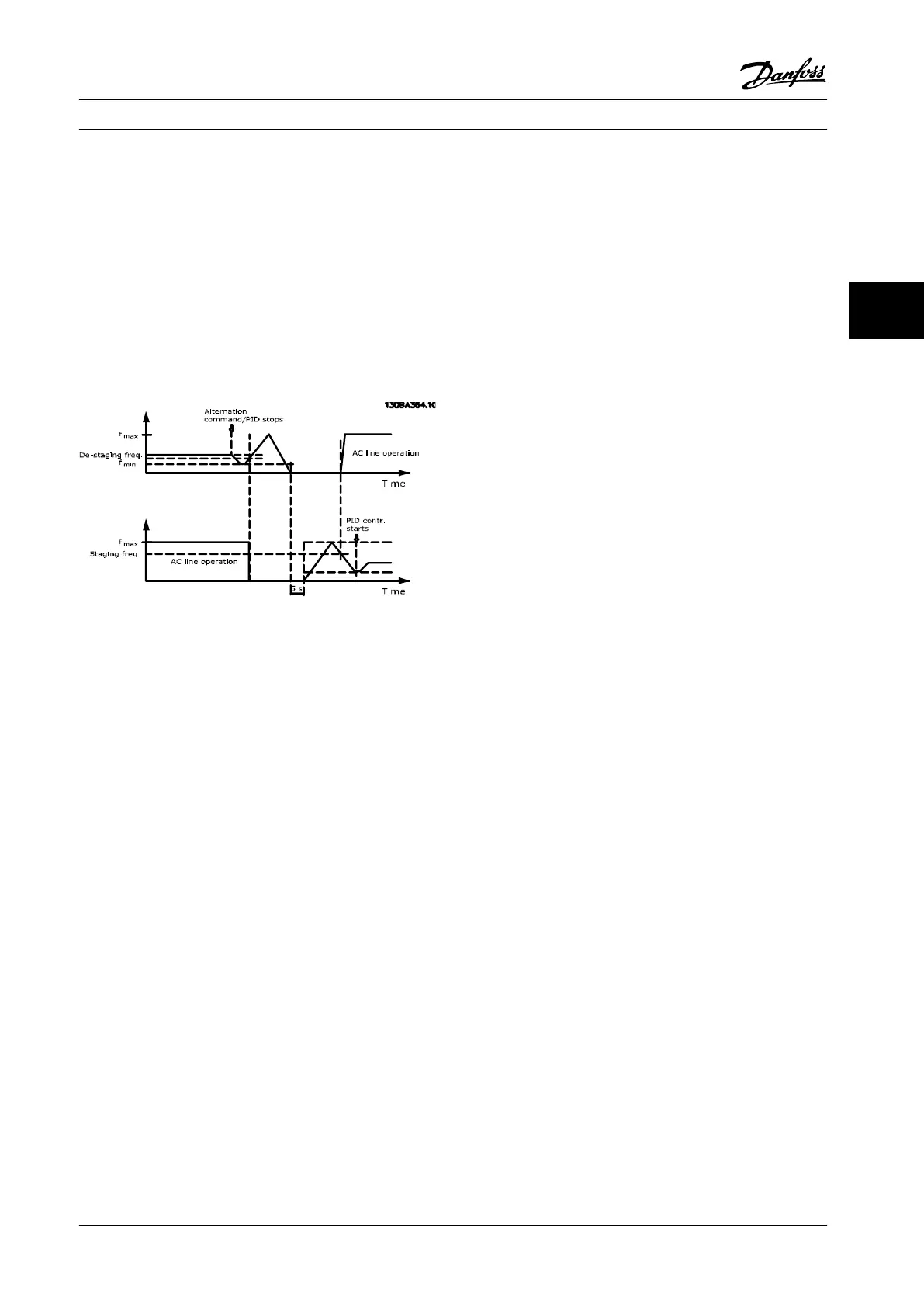

With lead pump alternation enabled, a maximum of two

pumps are controlled. At an alternation command, the PID

stops, the lead pump ramps to minimum frequency (f

min

)

and, after a delay, it ramps to maximum frequency (f

max

).

When the speed of the lead pump reaches the de-staging

frequency, the xed-speed pump is cut out (de-staged).

The lead pump continues to ramp up and then ramps

down to a stop and the two relays are cut out.

Figure 4.10 Lead Pump Alternation

After a time delay, the relay for the xed-speed pump cuts

in (staged) and this pump becomes the new lead pump.

The new lead pump ramps up to maximum speed and

then down to minimum speed. When ramping down and

reaching the staging frequency, the old lead pump is now

cut in (staged) on line power as the new xed-speed

pump.

If the lead pump has been running at minimum frequency

(f

min

) for a programmed amount of time, with a xed-

speed pump running, the lead pump contributes little to

the system. When programmed value of the timer expires,

the lead pump is removed, avoiding water heating

problems.

4.3.4

System Status and Operation

If the lead pump goes into sleep mode, the function is

displayed on the LCP. It is possible to alternate the lead

pump into a sleep mode condition.

When the cascade controller is enabled, the operation

status for each pump and the cascade controller is

displayed on the LCP. Information displayed includes:

•

Pumps status is a readout of the status for the

relays assigned to each pump. The display shows

pumps that are disabled, o, running on the

adjustable frequency drive, or running on the line

power/motor starter.

•

Cascade status is a readout of the status for the

cascade controller. The display shows that the

cascade controller is disabled, all pumps are o,

and emergency has stopped all pumps, all pumps

are running, xed-speed pumps are being

staged/de-staged and lead pump alternation is

occurring.

•

De-stage at no-ow ensures that all xed-speed

pumps are stopped individually until the no-ow

status disappears.

Application Examples Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 109

4 4

Loading...

Loading...