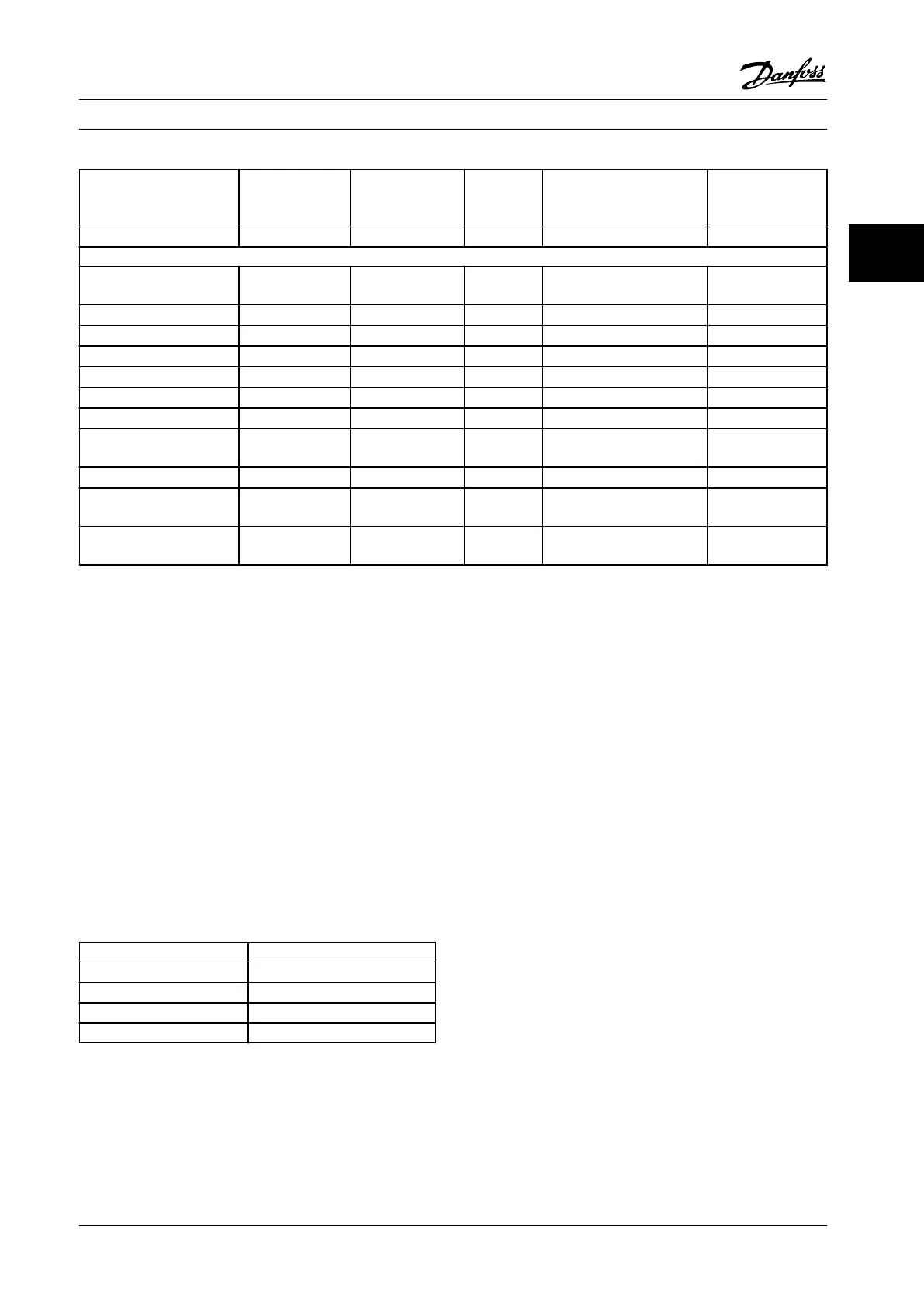

Basic standard

Burst

2)

IEC 61000-4-42)

Surge

2)

IEC 61000-4-5

ESD

2)

IEC

61000-4-2

Radiated electromagnetic

eld

IEC 61000-4-3

RF common

mode voltage

IEC 61000-4-6

Acceptance criterion B B B A A

Voltage range: 200–240 V, 380–500 V, 525–600 V, 525–690 V

Line

4 kV CM

2 kV/2 Ω DM

4 kV/12 Ω CM

— —

10 V

RMS

Motor

4 kV CM

4 kV/2 Ω

1)

— —

10 V

RMS

Brake 4 kV CM

4 kV/2 Ω

1)

— —

10 V

RMS

Load sharing 4 kV CM

4 kV/2 Ω

1)

— —

10 V

RMS

Control wires

2 kV CM

2 kV/2 Ω

1)

— —

10 V

RMS

Standard bus 2 kV CM

2 kV/2 Ω

1)

— —

10 V

RMS

Relay wires 2 kV CM

2 kV/2 Ω

1)

— —

10 V

RMS

Application and serial

communication options

2 kV CM

2 kV/2 Ω

1)

— —

10 V

RMS

LCP cable

2 kV CM

2 kV/2 Ω

1)

— —

10 V

RMS

External 24 V DC

2 V CM

0.5 kV/2 Ω DM

1 kV/12 Ω CM

— —

10 V

RMS

Enclosure

— —

8 kV AD

6 kV CD

10 V/m —

Table 3.7 EMC Immunity Form

1) Injection on cable shield

2) Values typically obtained by testing

3.2.5

Motor Insulation

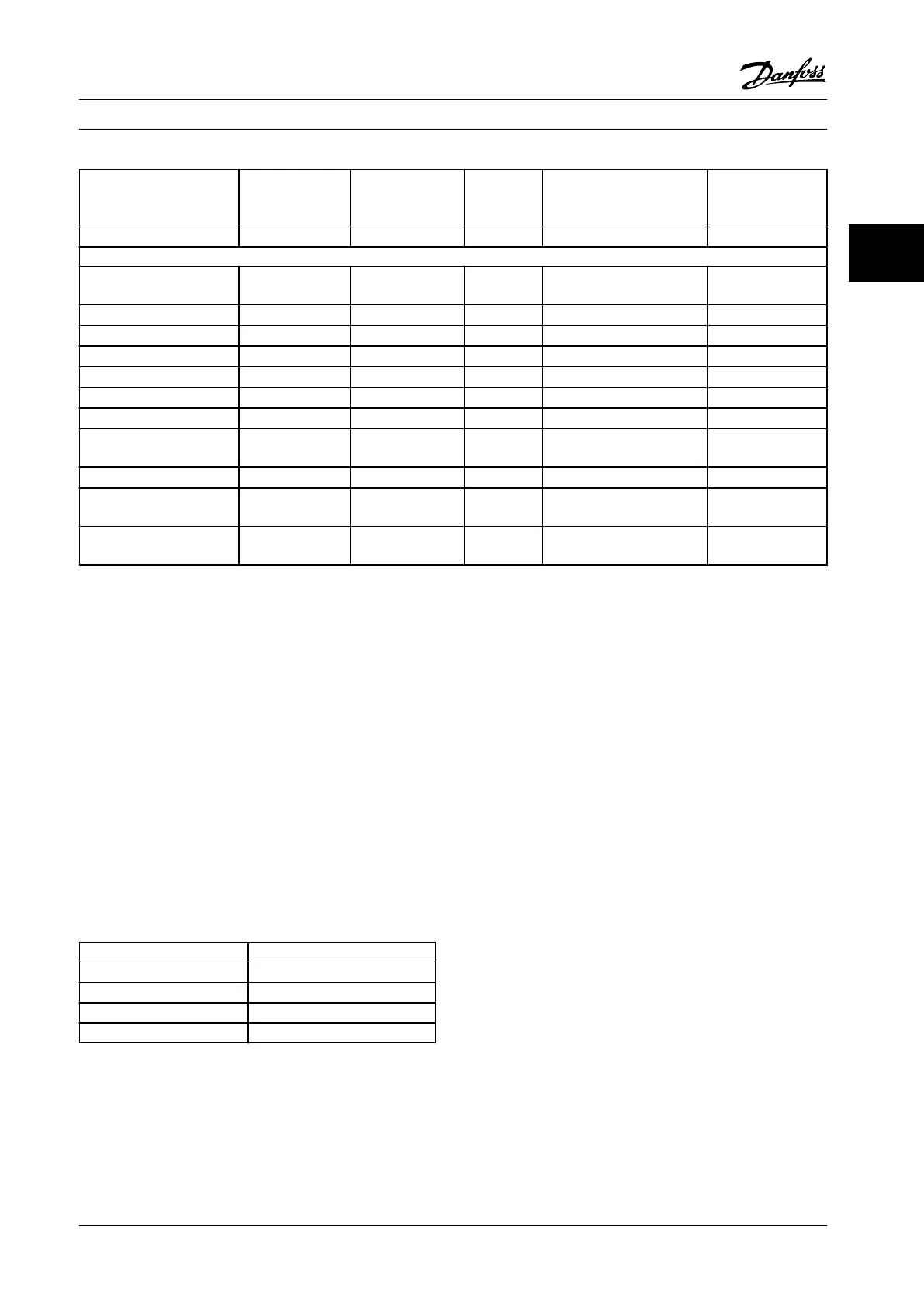

Modern motors for use with adjustable frequency drives

have a high degree of insulation to account for new

generation high-eciency IGBTs with high dU/dt. For

retrot in old motors, conrm the motor insulation or

mitigate with dU/dt lter or, if necessary, a sine-wave lter.

For motor cable lengths ≤ the maximum cable length

listed in chapter 7.5 Cable Specications, the motor

insulation ratings listed in Table 3.8 are recommended. If a

motor has lower insulation rating, it is recommended to

use a dU/dt or sine-wave lter.

Nominal AC line voltage [V] Motor insulation [V]

U

N

≤420

Standard U

LL

=1300

420 V< U

N

≤ 500 Reinforced U

LL

=1600

500 V< U

N

≤ 600 Reinforced U

LL

=1800

600 V< U

N

≤ 690 Reinforced U

LL

=2000

Table 3.8 Motor Insulation

3.2.6

Motor Bearing Currents

To minimize bearing and shaft currents, ground the

following to the driven machine:

•

Adjustable frequency drive

•

Motor

•

Driven machine

Standard mitigation strategies

1. Use an insulated bearing.

2. Apply rigorous installation procedures:

2a Ensure that the motor and load motor

are aligned.

2b Strictly follow the EMC Installation

guideline.

2c Reinforce the PE so the high frequency

impedance is lower in the PE than the

input power leads.

2d Provide a good high frequency

connection between the motor and the

adjustable frequency drive, for instance,

by a shielded cable which has a 360°

connection in the motor and the

adjustable frequency drive.

System Integration Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 49

3 3

Loading...

Loading...