3.8.9.3 Adjustable Frequency Drive with

Modbus RTU

The adjustable frequency drive communicates in Modbus

RTU format over the built-in RS485 interface. Modbus RTU

provides access to the control word and bus reference of

the adjustable frequency drive.

The control word allows the Modbus master to control

several important functions of the adjustable frequency

drive:

•

Start

•

Stop of the adjustable frequency drive in various

ways:

-

Coast stop

-

Quick stop

-

DC brake stop

-

Normal (ramp) stop

•

Reset after a fault trip

•

Run at a variety of preset speeds

•

Run in reverse

•

Change the active set-up

•

Control the adjustable frequency drive’s built-in

relay

The bus reference is commonly used for speed control. It is

also possible to access the parameters, read their values,

and, where possible, write values to them. This permits a

range of control options, including controlling the setpoint

of the adjustable frequency drive when its internal PI

controller is used.

3.8.9.4

Network Conguration

To enable Modbus RTU on the adjustable frequency drive,

set the following parameters:

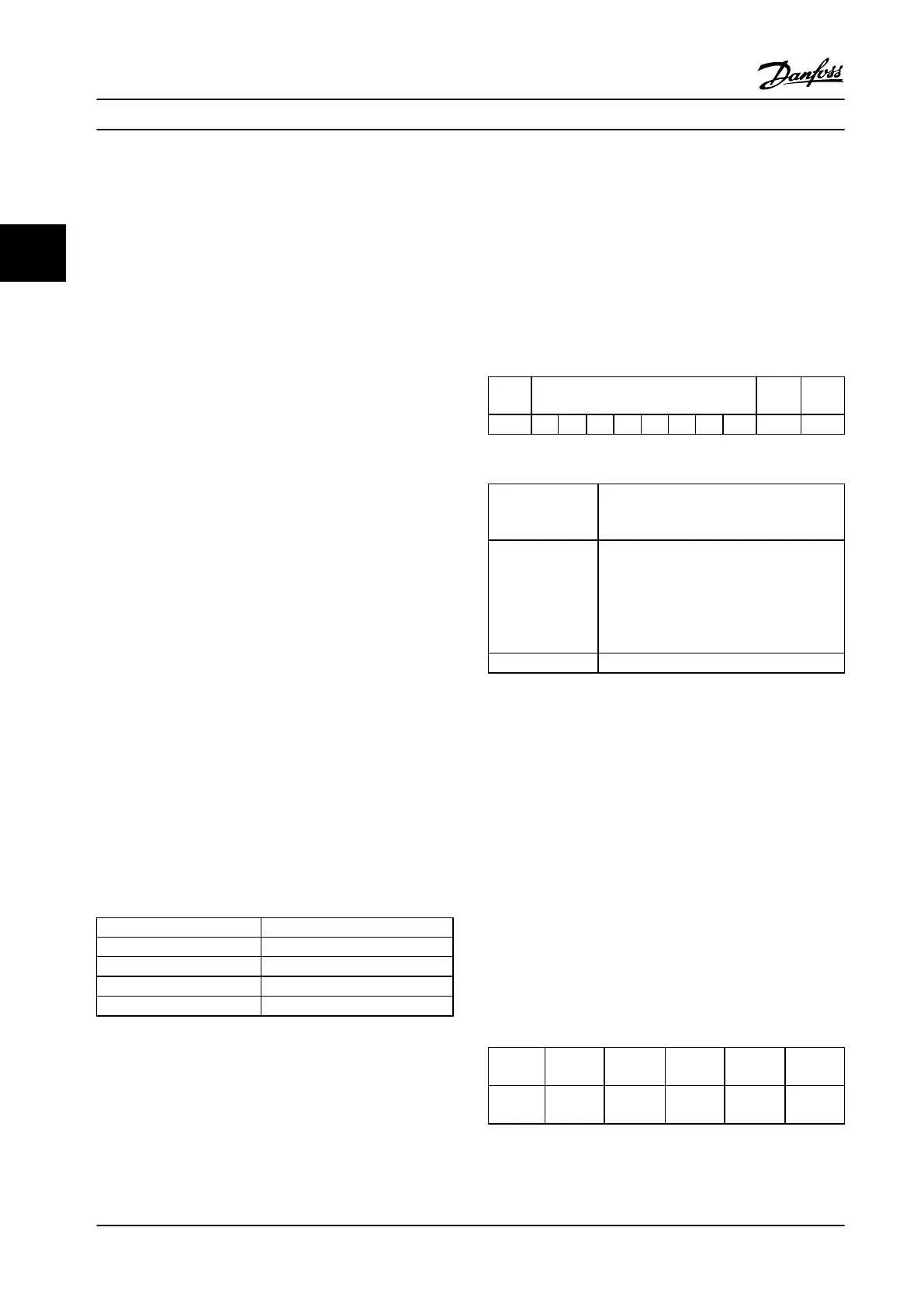

Parameter Setting

8-30 Protocol Modbus RTU

8-31 Address 1-247

8-32 Baud Rate 2400-115200

8-33 Parity / Stop Bits Even parity, 1 stop bit (default)

Table 3.33 Modbus RTU Parameters

3.8.10

Modbus RTU Message Framing

Structure

3.8.10.1 Adjustable Frequency Drive with

Modbus RTU

The controllers are set up to communicate on the Modbus

network using RTU mode, with each byte in a message

containing 2 4-bit hexadecimal characters. The format for

each byte is shown in Table 3.34.

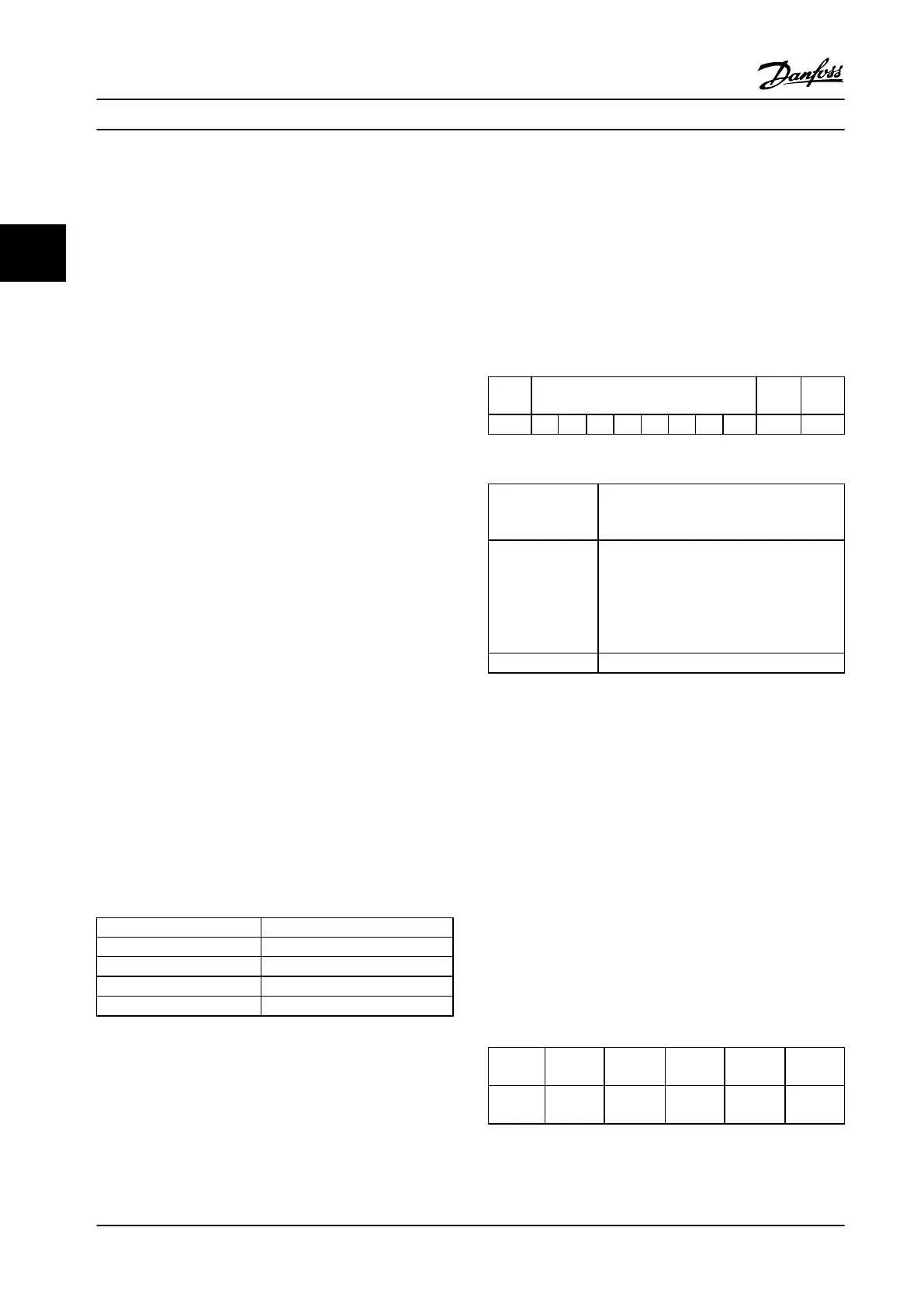

Start

bit

Data byte Stop/

parity

Stop

Table 3.34 Format for Each Byte

Coding system 8–bit binary, hexadecimal 0–9, A–F.

Two hexadecimal characters contained in

each 8-bit eld of the message.

Bits per byte 1 start bit.

8 data bits, least signicant bit sent rst;

1 bit for even/odd parity; no bit for no

parity.

1 stop bit if parity is used; 2 bits if no

parity.

Error check eld Cyclical redundancy check (CRC).

3.8.10.2 Modbus RTU Message Structure

The transmitting device places a Modbus RTU message

into a frame with a known beginning and ending point.

This allows receiving devices to begin at the start of the

message, read the address portion, determine which

device is addressed (or all devices, if the message is

broadcast), and to recognize when the message is

completed. Partial messages are detected, and errors are

set as a result. Characters for transmission must be in

hexadecimal 00 to FF format in each eld. The adjustable

frequency drive continuously monitors the network bus,

also during silent intervals. When the rst eld (the address

eld) is received, each adjustable frequency drive or device

decodes it to determine which device is being addressed.

Modbus RTU messages addressed to zero are broadcast

messages. No response is permitted for broadcast

messages. A typical message frame is shown in Table 3.35.

Start Address Function Data CRC

check

End

T1-T2-T3-

T4

8 bits 8 bits N x 8 bits 16 bits T1-T2-T3-

T4

Table 3.35 Typical Modbus RTU Message Structure

System Integration

VLT

®

AQUA Drive FC 202

88 Danfoss A/S © 09/2014 All rights reserved. MG20N622

33

Loading...

Loading...