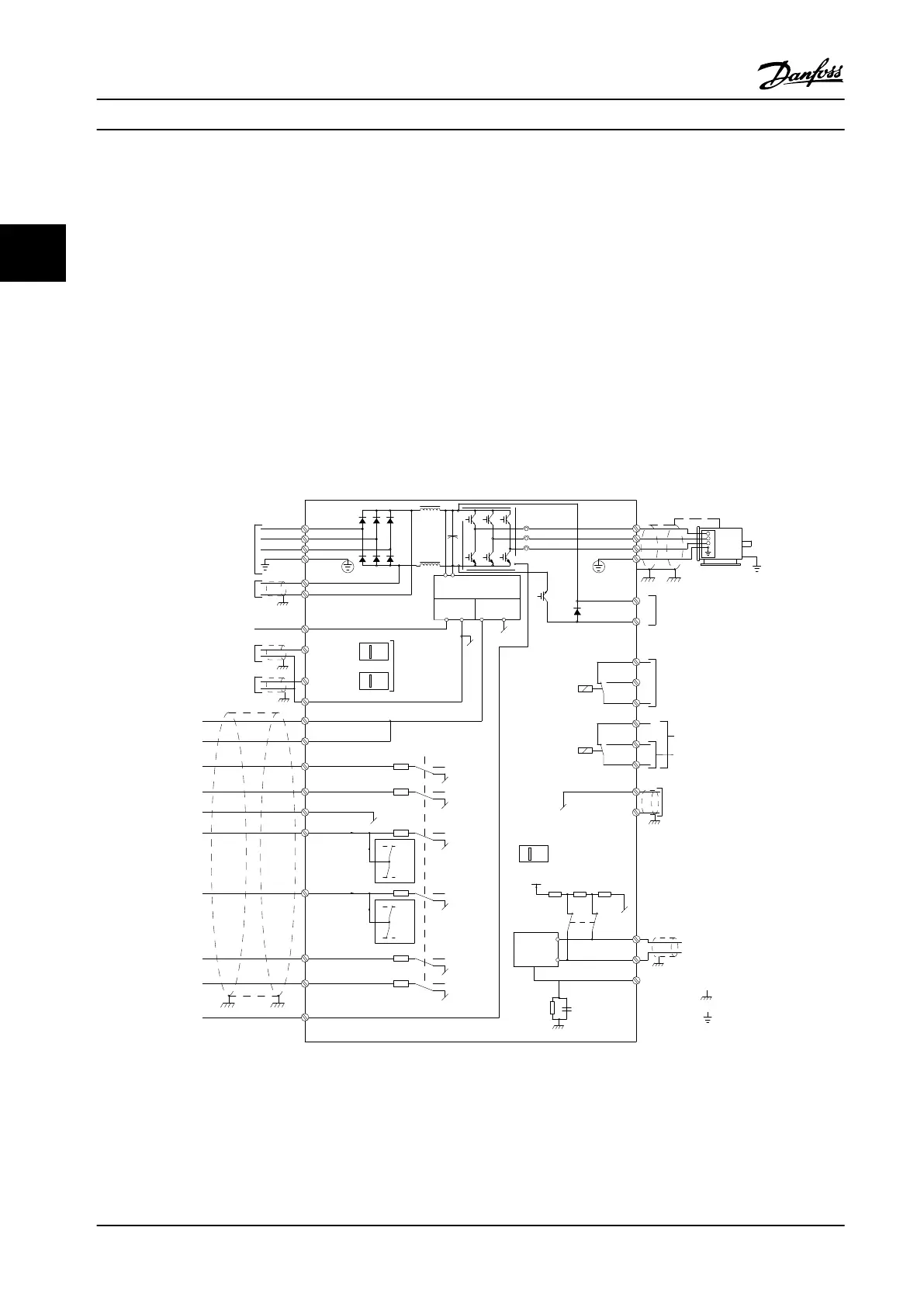

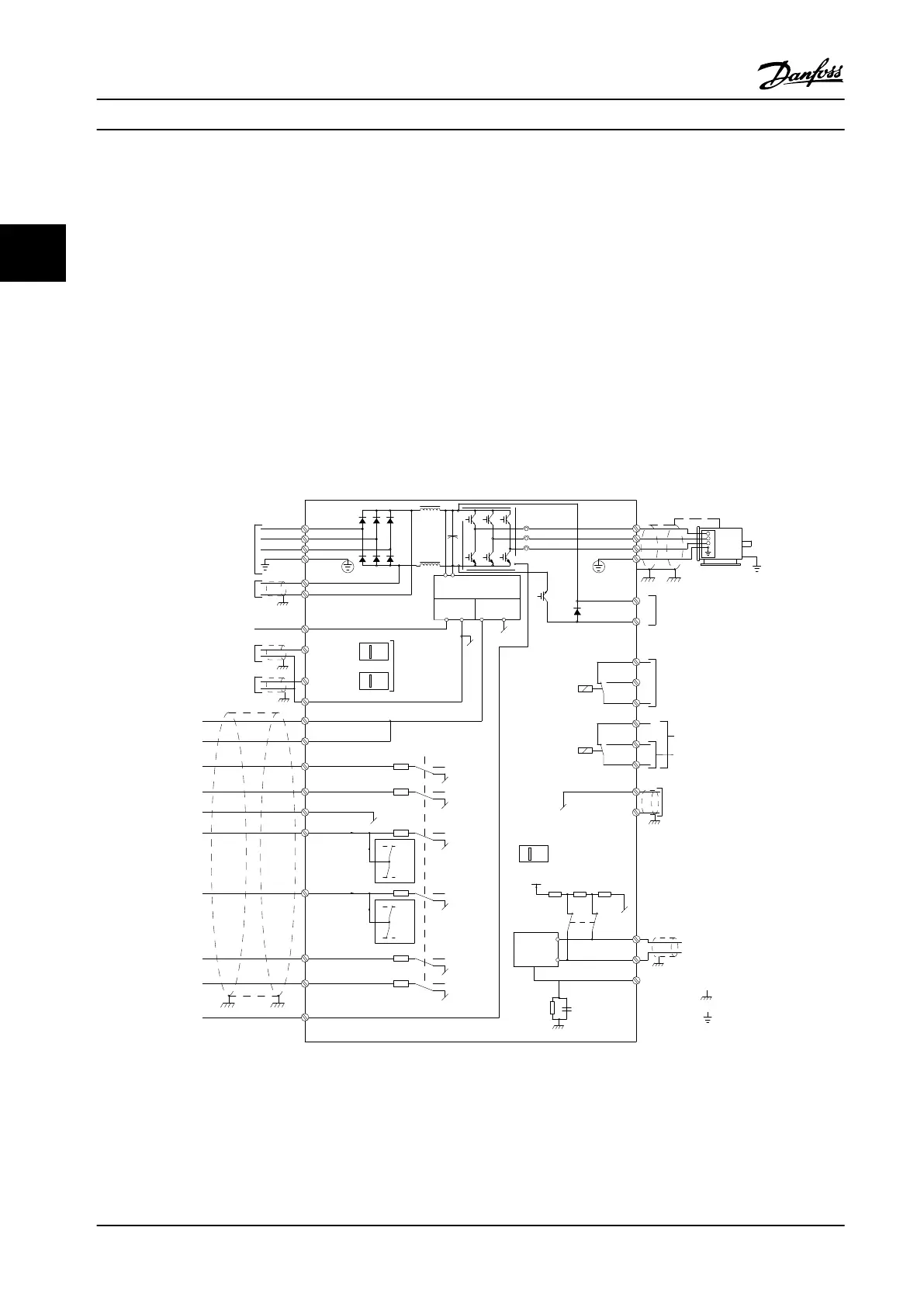

3.5 Additional Inputs and Outputs

3.5.1 Wiring Schematic

When wired and properly programmed, the control terminals provide:

•

Feedback, reference, and other input signals to the adjustable frequency drive.

•

Output status and fault conditions from the adjustable frequency drive.

•

Relays to operate auxiliary equipment.

•

A serial communication interface.

•

24 V common.

Control terminals are programmable for various functions by selecting parameter options through the local control panel

(LCP) on the front of the unit or external sources. Most control wiring is customer-supplied, unless specied in the factory

order.

+ - + -

S202

**

*

Motor

Analog Output

relay1

relay2

ON=Terminated

OFF=Open

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

12 (+24 V OUT)

13 (+24 V OUT)

37 (D IN)

18 (D IN)

(COM D IN)

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0/4–20 mA

240 V AC, 2 A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

: Chassis

: Ground

240 V AC, 2 A

400 V AC, 2 A

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

20

10 V DC

15 mA 130/200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

0 V

5 V

S801

RS-485

03

24 V DC

02

01

05

04

06

27

24 V

0 V

0 V

24 V

29

1 2

ON

S201

ON

21

ON=0/4–20 mA

OFF=0/-10 V DC -

+10 V DC

95

P 5-00

21

ON

S801

(R+) 82

(R-) 81

130BD552.10

3-phase

power

input

DC bus

+10 V DC

0/-10 V DC-

+10 V DC

0/4–20 mA

0/-10 V DC-

+10 V DC

0/4–20 mA

Switch Mode

Power Supply

Brake

resistor

RS-485

Interface

Figure 3.20 Basic Wiring Schematic

A=Analog, D=Digital

*Terminal 37 (optional) is used for STO. For STO installation instructions, refer to the VLT

®

Safe Torque O Instruction Manual.

**Do not connect cable shield.

System Integration

VLT

®

AQUA Drive FC 202

64 Danfoss A/S © 09/2014 All rights reserved. MG20N622

33

Loading...

Loading...