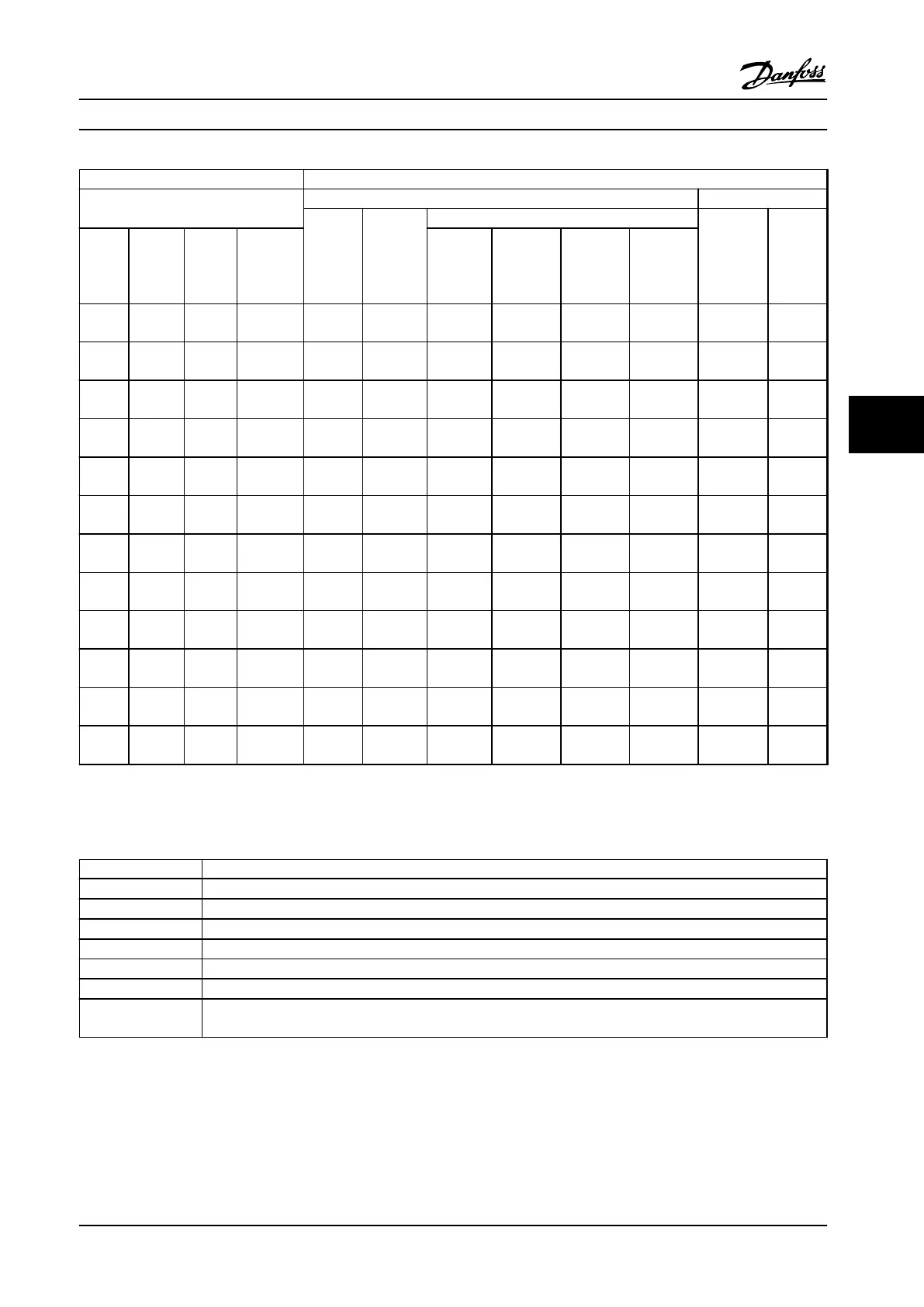

FC 202 Vertical braking 40% duty cycle

Adjustable frequency drive data

Brake resistor data Installation

R

rec

[Ω]

P

br,cont.

[kW (hp)]

Danfoss part number Cable

cross-

section

[mm

2

(AWG)]

Thermo

relay

[A]

Line

power

type

P

m

[kW

(hp)]

R

min

[Ω]

R

br,nom

[Ω]

Wire IP54

Screw

terminal

IP21

Screw

terminal

IP65

Bolt

connection

IP20

T7

315

(425)

2.3 3.7 3.2 - - - - - - -

T7

400

(550)

2.3 2.9 2.5 - - - - - - -

T7

450

(600)

2.0 2.6 2.3 - - - - - - -

T7

500

(650)

1.9 2.3 2.0 - - - - - - -

T7

560

(750)

1.5 2.1 1.6 - - - - - - -

T7

630

(850)

1.4 1.8 1.4 - - - - - - -

T7

710

(950)

1.2 1.6 2 x 2.6 - - - - - - -

T7

800

(1075)

1.1 (1.5) 1.4 2 x 2.2 - - - - - - -

T7

900

(1200)

1.0 1.3 2 x 2.0 - - - - - - -

T7

1000

(1350)

0.9 1.1 (1.5) 3 x 2.6 - - - - - - -

T7

1200

(1600)

0.8 1.0 3 x 2.4 - - - - - - -

T7

1400

(1875)

0.6 0.8 3 x 2.0 - - - - - - -

Table 6.14 T7, Vertical Braking 40% Duty Cycle, Recommended Brake Resistors

6.2.6

Alternative Brake Resistors, T2 and T4

Line power Voltage class

P

m

Rated motor size for adjustable frequency drive type

R

min

Minimum permissible brake resistor - by adjustable frequency drive

R

rec

Recommended brake resistor resistance of Danfoss brake resistors

Duty cycle P

br,cont.

x100/Pm

Part number Danfoss brake resistor order numbers

P

br,cont.

Brake resistor average rated power.

R

br,nom

The nominal (calculated) resistor value to ensure a braking energy on the motor shaft of 150/160/110% for 1

minute

Table 6.15 Abbreviations used in Table 6.16 to Table 6.17

Type code and Selection

Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 139

6 6

Loading...

Loading...