3.4.13 Brake Resistor Cabling

EMC (twisted cables/shielding)

To meet the specied EMC performance of the adjustable

frequency drive, use shielded cables/wires. If non-shielded

wires are used, it is recommended to twist the wires to

reduce the electrical noise from the wires between the

brake resistor and the adjustable frequency drive.

For enhanced EMC performance, use a metal shield.

3.4.14 Brake Resistor and Brake IGBT

Brake resistor power monitor

In addition, the braking energy monitor function makes it

possible to read out the momentary power and the mean

power for a selected time period. The brake can also

monitor the power energizing and make sure it does not

exceed a limit selected in 2-12 Brake Power Limit (kW). In

2-13 Brake Power Monitoring, select the function to carry

out when the power transmitted to the brake resistor

exceeds the limit set in 2-12 Brake Power Limit (kW).

NOTICE!

Monitoring the braking energy does not fulll a safety

function. The brake resistor circuit is not ground leakage

protected.

The brake is protected against short-circuiting of the brake

resistor, and the brake transistor is monitored to ensure

that short-circuiting of the transistor is detected. Use a

relay or digital output to protect the brake resistor against

overloading in the event of a fault in the adjustable

frequency drive.

Overvoltage control (OVC) can be selected as an alternative

brake function in 2-17 Over-voltage Control. If the DC link

voltage increases, this function is active for all units. The

function ensures that a trip can be avoided. This is done

by increasing the output frequency to limit the voltage

from the DC link. It is a useful function, e.g., if the ramp-

down time is too short since tripping of the adjustable

frequency drive is avoided. In this situation, the ramp-

down time is extended.

3.4.15

Energy Eciency

Eciency of the adjustable frequency drive

The load on the adjustable frequency drive has little eect

on its eciency.

This also means that the adjustable frequency drive

eciency does not change when other U/f characteristics

are selected. However, the U/f characteristics do inuence

the eciency of the motor.

The eciency declines a little when the switching

frequency is set to a value above 5 kHz. The eciency is

also slightly reduced when the motor cable is longer than

30 m (100 ft).

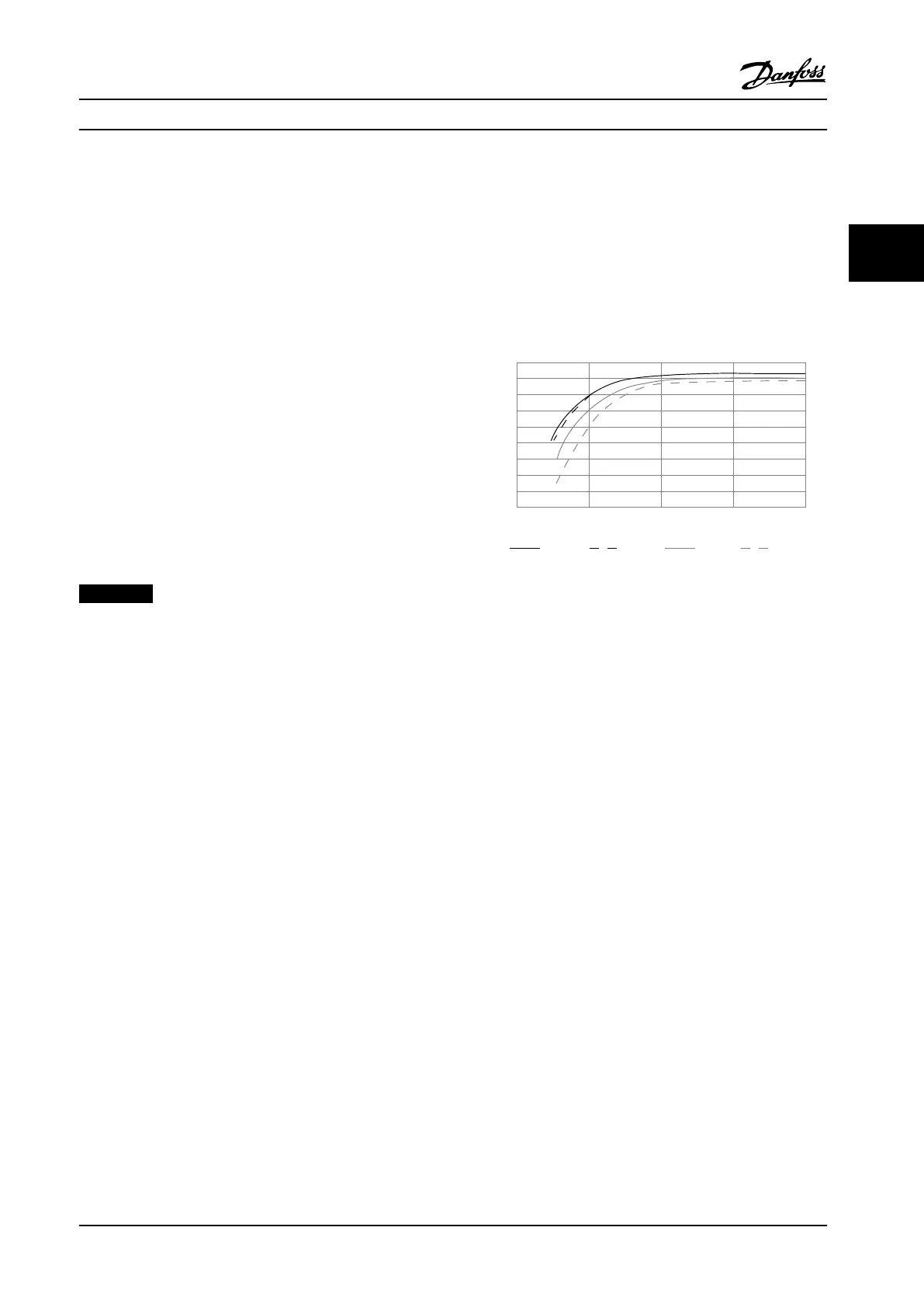

Eciency calculation

Calculate the eciency of the adjustable frequency drive at

dierent loads based on Figure 3.19. Multiply the factor in

this graph with the specic eciency factor listed in

chapter 7.1 Electrical Data.

1.0

0.99

0.98

0.97

0.96

0.95

0.93

0.92

0% 50% 100% 200%

0.94

Relative Eciency

130BB252.11

1.01

150%

% Speed

100% load 75% load 50% load 25% load

Figure 3.19 Typical Eciency Curves

Example: Assume a 55 kW (75 hp), 380–480 V AC

adjustable frequency drive with 25% load at 50% speed.

The graph is showing 0.97 rated eciency for a 55 kW (75

hp) adjustable frequency drive is 0.98. The actual eciency

is then: 0.97 x 0.98=0.95.

Motor eciency

The eciency of a motor connected to the adjustable

frequency drive depends on magnetizing level. The

eciency of the motor depends on the type of motor.

•

In the range of 75–100% of the rated torque, the

eciency of the motor is practically constant,

both when it is controlled by the adjustable

frequency drive, and when it runs directly on line

power.

•

The inuence from the U/f characteristic on small

motors is marginal. However, in motors from 11

kW (15 hp) and up, the eciency advantage is

signicant.

•

The switching frequency does not aect the

eciency of small motors. Motors from 11 kW (15

hp) and up have their eciency improved 1–2%.

This is because the sine-shape of the motor

current is almost perfect at high switching

frequency.

System eciency

To calculate the system eciency, multiply the eciency of

the adjustable frequency drive by the eciency of the

motor.

System Integration

Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 63

3 3

Loading...

Loading...