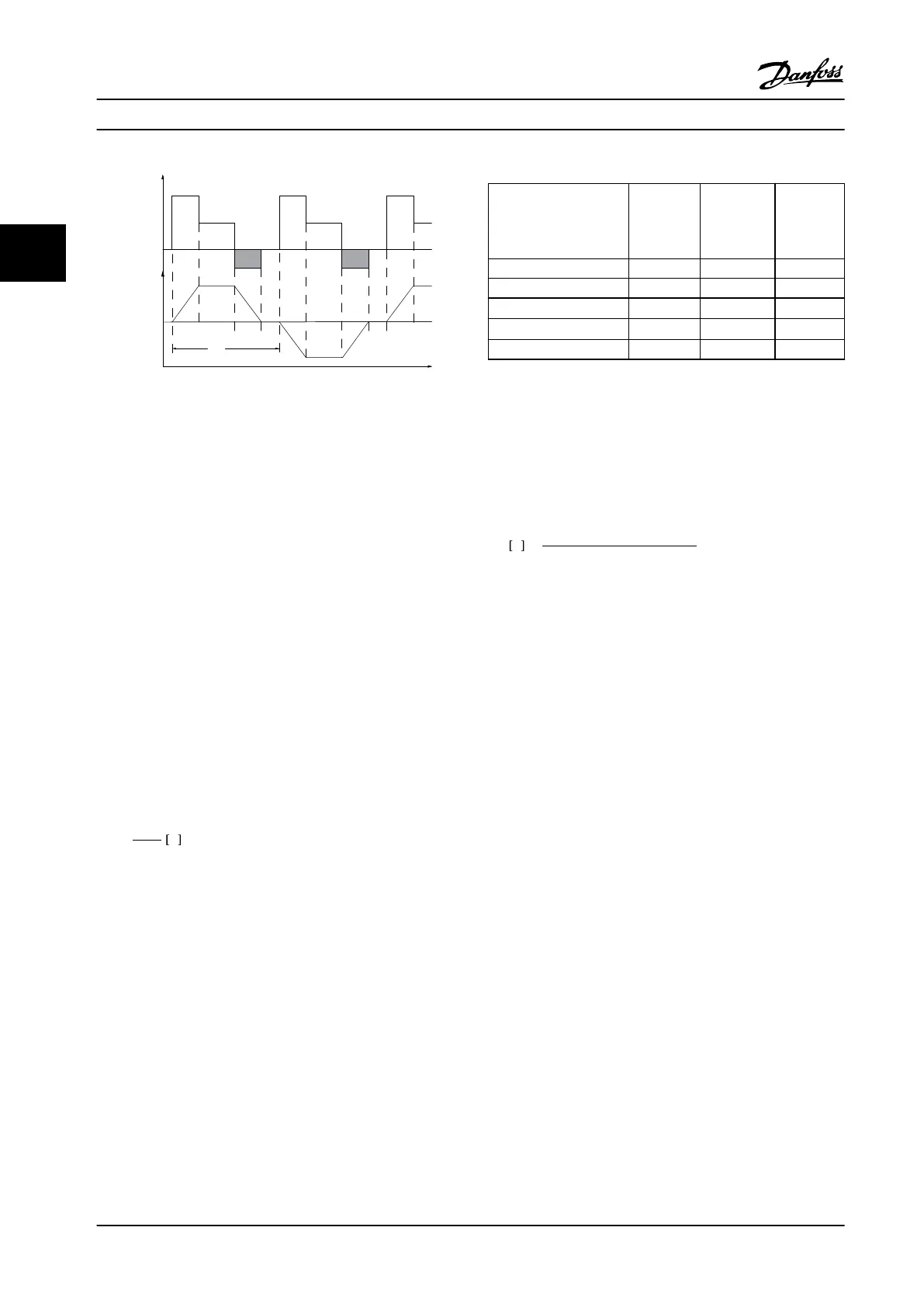

T

ta

tc

tb

to ta

tc

tb

to ta

130BA167.10

Load

Time

Speed

Figure 3.18 Brake Resistor Duty Cycle

Calculate the intermittent duty cycle for the resistor as

follows:

Duty cycle=t

b

/T

T =cycle time in seconds

t

b

is the braking time in seconds (of the cycle time)

Danfoss oers brake resistors with duty cycles of 5%, 10%,

and 40%. When a 10% duty cycle is applied, the brake

resistors absorb braking energy for 10% of the cycle time.

The remaining 90% of the cycle time is used to dissipate

excess heat.

Ensure the brake resistor is dimensioned for the required

braking time.

Brake resistance calculation

To prevent the adjustable frequency drive from cutting out

for protection when the motor brakes, select resistor values

on the basis of the peak braking energy and the

intermediate circuit voltage. Calculate resistance of the

brake resistor as follows:

R

br

=

Udc

2

P

peak

Ω

The brake resistor performance depends on the DC link

voltage (U

dc

).

U

dc

is the voltage at which the brake is activated. The FC-

series brake function is settled depending on the line

power supply.

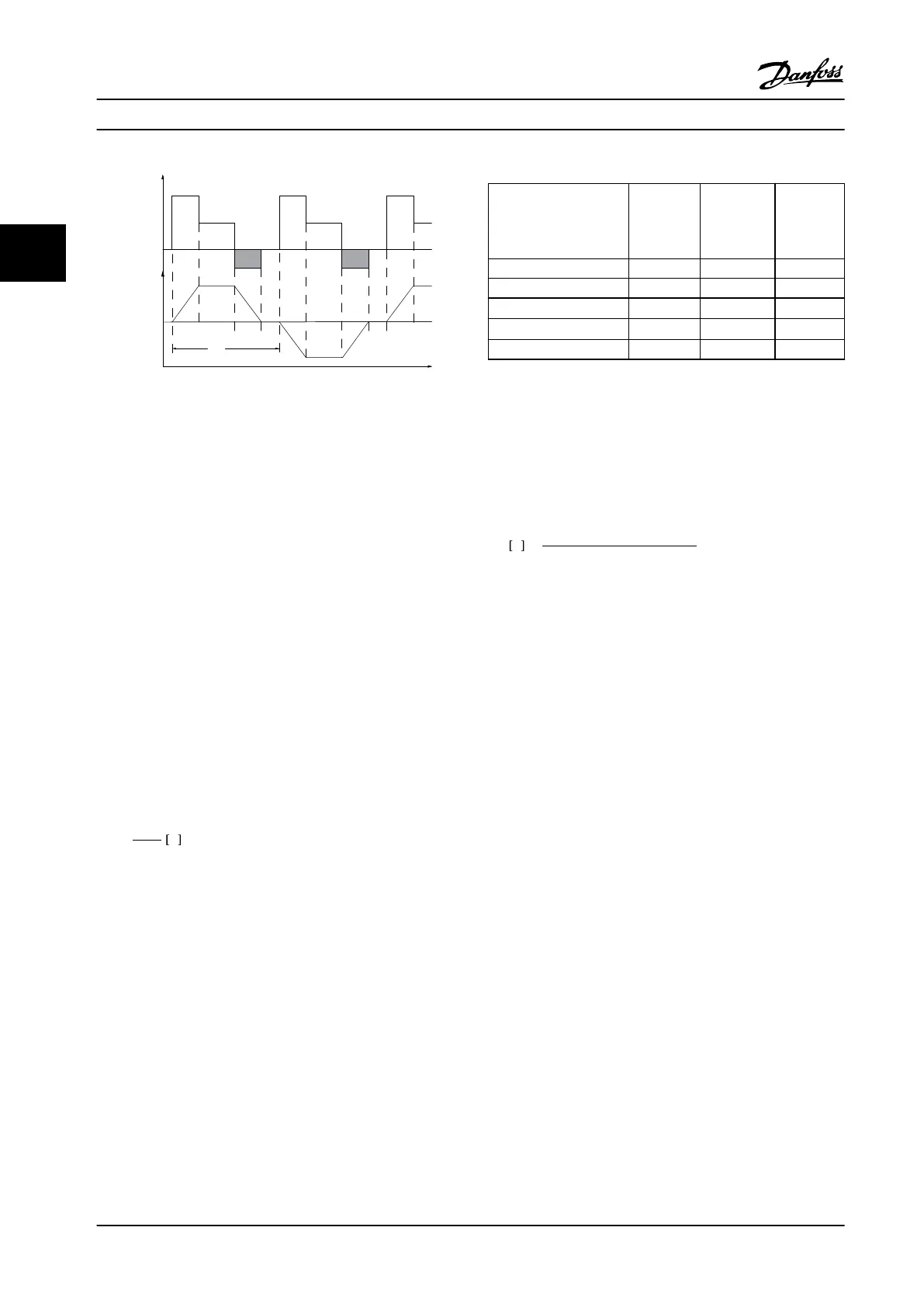

line power supply input

[V AC]

Brake

active

[V DC]

High

voltage

warning

[V DC]

Over

voltage

alarm

[V DC]

FC 202 3x200-240 390 405 410

FC 202 3x380-480 778 810 820

FC 202 3x525-600

1)

943 965 975

FC 202 3x525-600

2)

1099 1109 1130

FC 202 3x525-690 1099 1109 1130

Table 3.18 DC link Voltage (U

dc

)

1) Enclosure sizes A, B, C

2) Enclosure sizes D, E, F

Use the brake resistance R

rec

, to ensure that the adjustable

frequency drive is able to brake at the highest braking

torque (M

br(%)

) of 160%. The formula can be written as:

R

rec

Ω =

U

dc

2

x100

P

motor

xM

br( % )

xη

VLT

xη

motor

η

motor

is typically at 0.90

η

VLT

is typically at 0.98.

When a higher brake resistor resistance is selected, 160%/

150%/110% braking torque cannot be obtained, and there

is a risk that the adjustable frequency drive cuts out of DC

Link overvoltage for protection.

For braking at lower torque, for example 80% torque, it is

possible to install a brake resistor with lower power rating.

Calculate size using the formula for calculating R

rec

.

Adjustable frequency drive D and F enclosure sizes contain

more than one brake chopper. Use a brake resistor for

each chopper for those enclosure sizes.

The VLT

®

Brake Resistor MCE 101 Design Guide contains the

most up-to-date selection data, and describes the

calculation steps in more detail, including:

•

Calculation of braking energy

•

Calculation of brake resistor peak power

•

Calculation of brake resistor average power

•

Braking of inertia

System Integration

VLT

®

AQUA Drive FC 202

62 Danfoss A/S © 09/2014 All rights reserved. MG20N622

33

Loading...

Loading...