V0913, 3.12

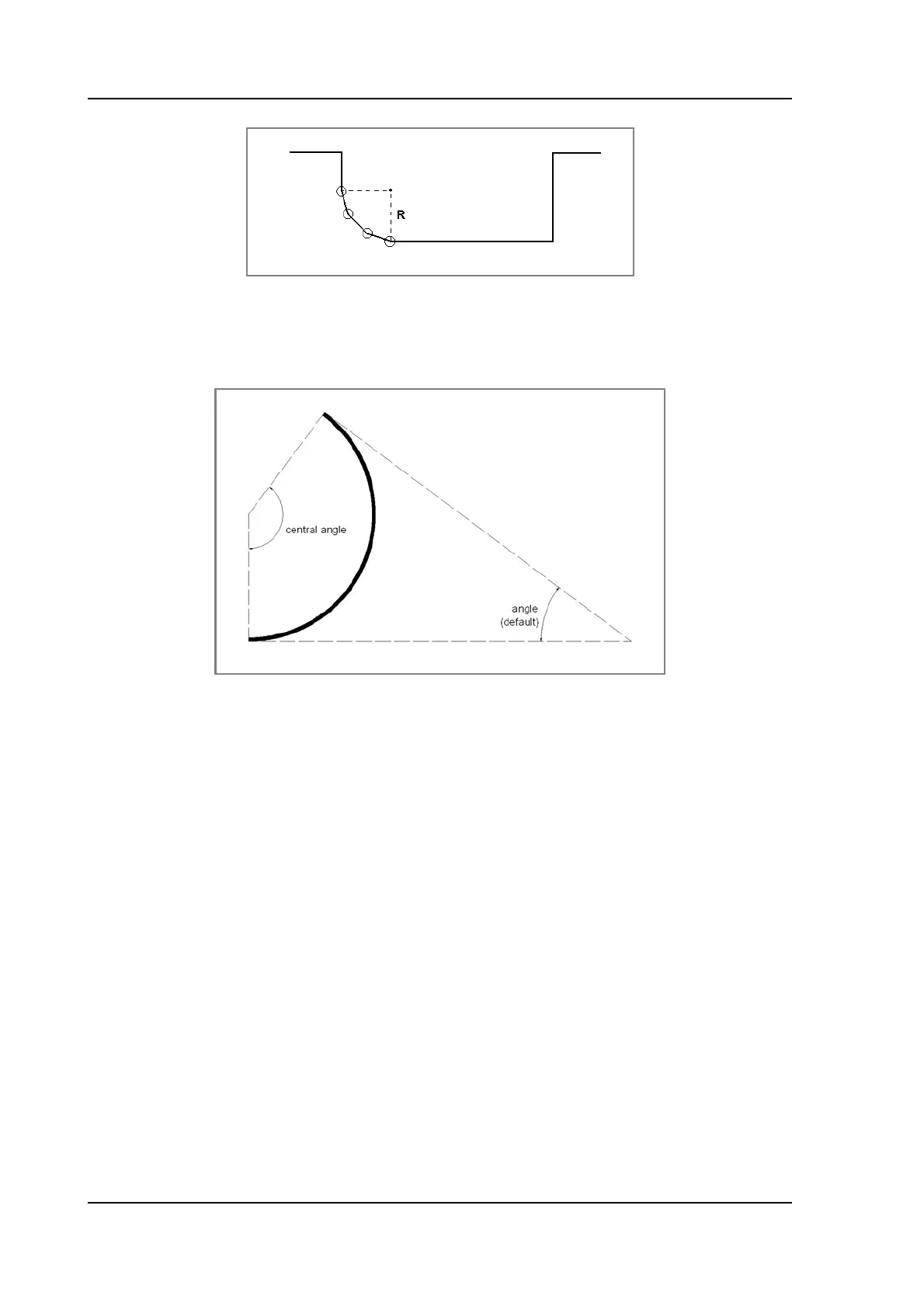

First you can choose the Angle Definition. The available definitions are:

• The default angle is the angle which could be programmed as standard.

• The central angle is the supplement of the default angle (i.e. 180 degrees - default

angle).

To apply the bumping method, the following parameters must be programmed:

Central angle

The supplement of the angle value to bend.

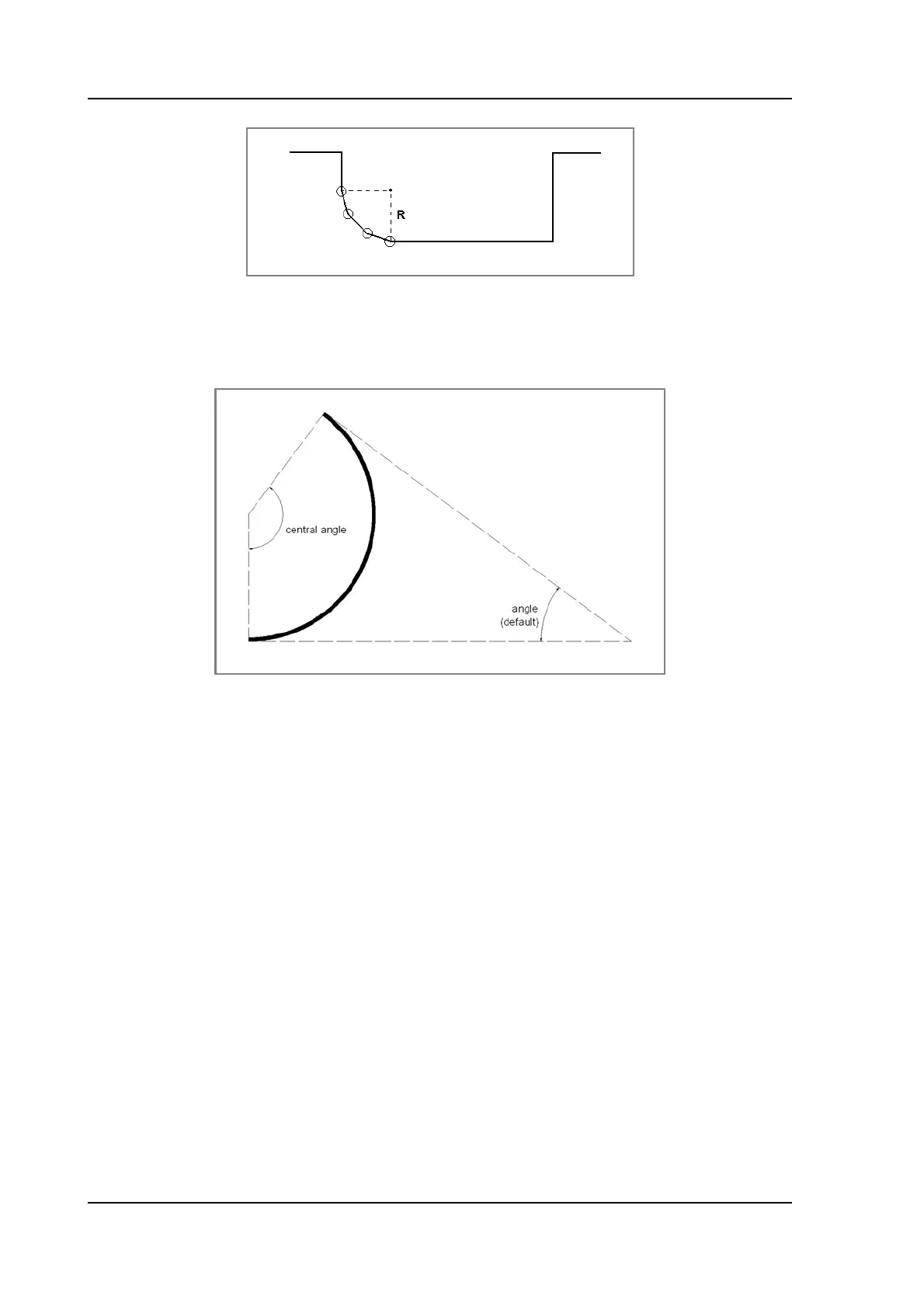

Radius

The intended radius which is programmed. As initial value the programmed product

thickness is used.

Number of segments

The number of segments in which the radius will be divided. The number of bends in this

radius is the number of segments plus 1.

The more segments you select, the more bends will be used to create the programmed

radius within a smaller tolerance. With a high number of segments you will need a

smaller V-die opening to be able to bend in a proper way.

Equal bumping-segments

When a product has a radius bend, the segment size is computed from the number of

segments, which has been defined by the user. Standard the first and last segment are

calculated half the size of the mid segments to obtain a better result. However, it can be

a problem selecting a die suitable to bend these small segments. Therefore the control

can calculate an equal size for all segments. This can be defined with this parameter.

• Disabled (no equal sizes)

Loading...

Loading...