V0913, 2.13

2.2.1. Product drawing dimensions

The drawing file can be organised in two ways:

• projection dimensions;

• cutting dimensions.

These ways are described in the following subparagraphs.

During operation in the DXF converter, it is possible to switch between cutting dimensions and

projection dimensions. This can be done in the DXF conversion settings.

Projection dimensions

In this situation all product sides and bend lines have the length of the resulting product. The

drawing does not represent the real size of the sheet that must be bent, but is merely a

representation of how the sheet is to be organised into bends and surfaces. When such a

drawing is loaded and converted, the converter will construct a product drawing with exactly

the same sizes as are present in the original drawing. Later on additional information is added

about material, sheet thickness and product dimensions. It is left to the control to create a

CNC program with proper axes positions that will result in a product as intended.

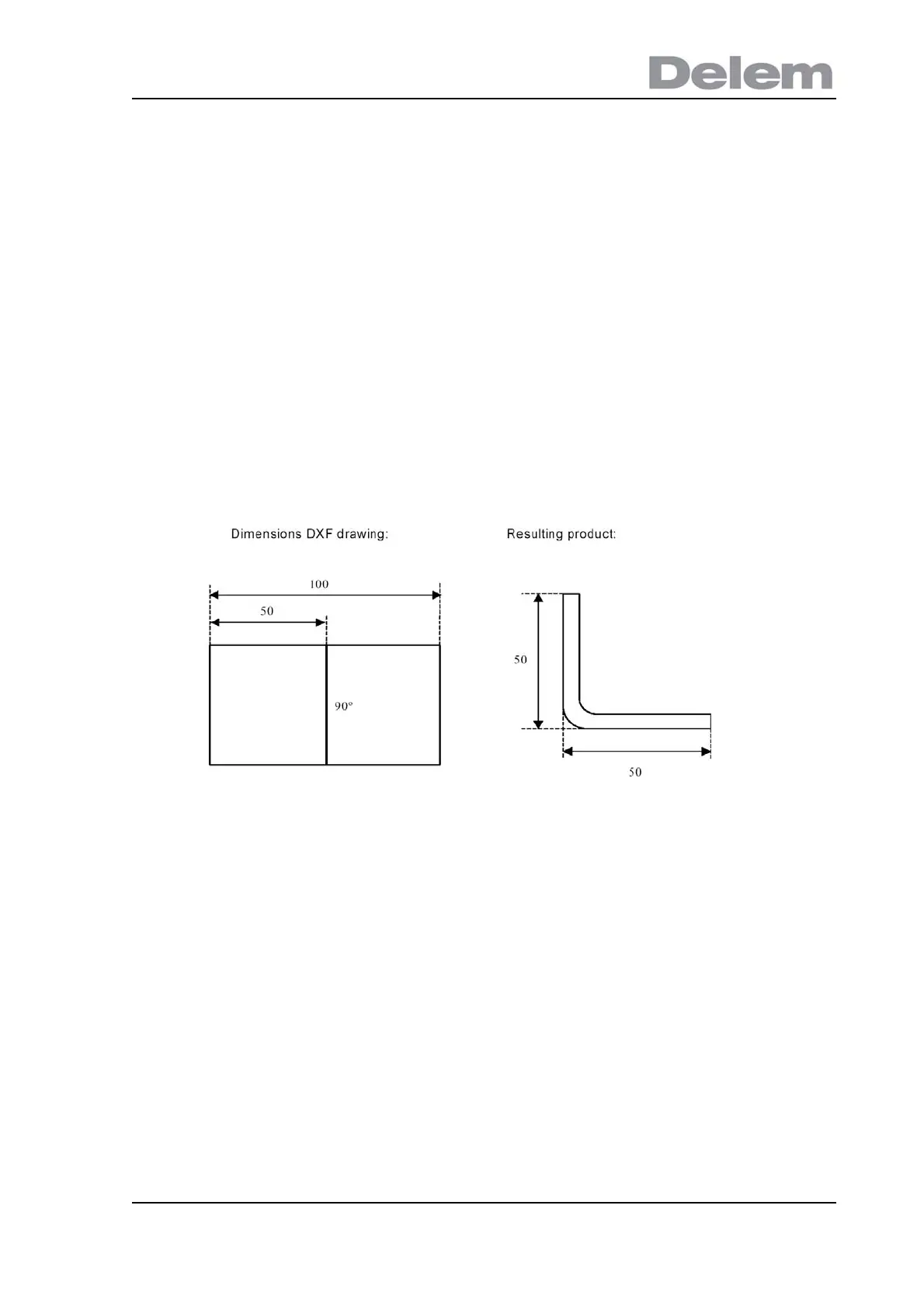

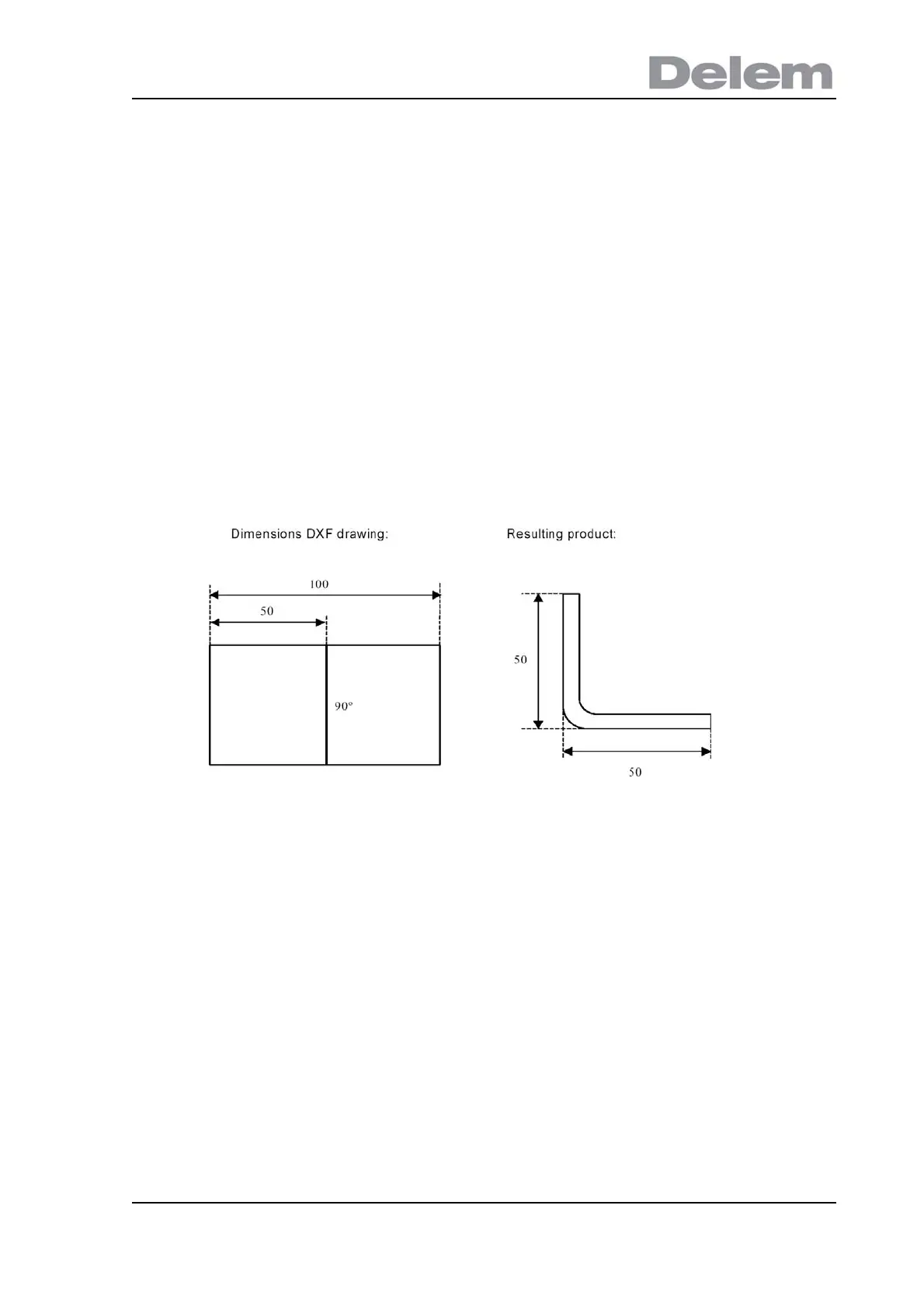

In this example, the length in the original DXF drawing may simply be 100, separated by a

bendline. The resulting product will consist of two sides, each with a length of 50.

The dimensions are defined as outside dimensions.

Cutting dimensions

In this case the DXF drawing represents the exact sheet, as it is cut and will be used to bend

a product of. When the DXF converter is set to convert cutting dimensions, based on material

and thickness of the sheet, bend allowance information is required during the conversion

process. If this information is not present the converter will ask for it.

The converter will use these dimensions and a bend-allowance table to construct a 3D

product drawing with projection dimensions. When the product is used in the control, the

same bend allowance table should be used to create a CNC program that can process a

sheet as shown in the original DXF drawing.

Loading...

Loading...