71 / 97

Introduction Manual ENC66

eckelmann.de

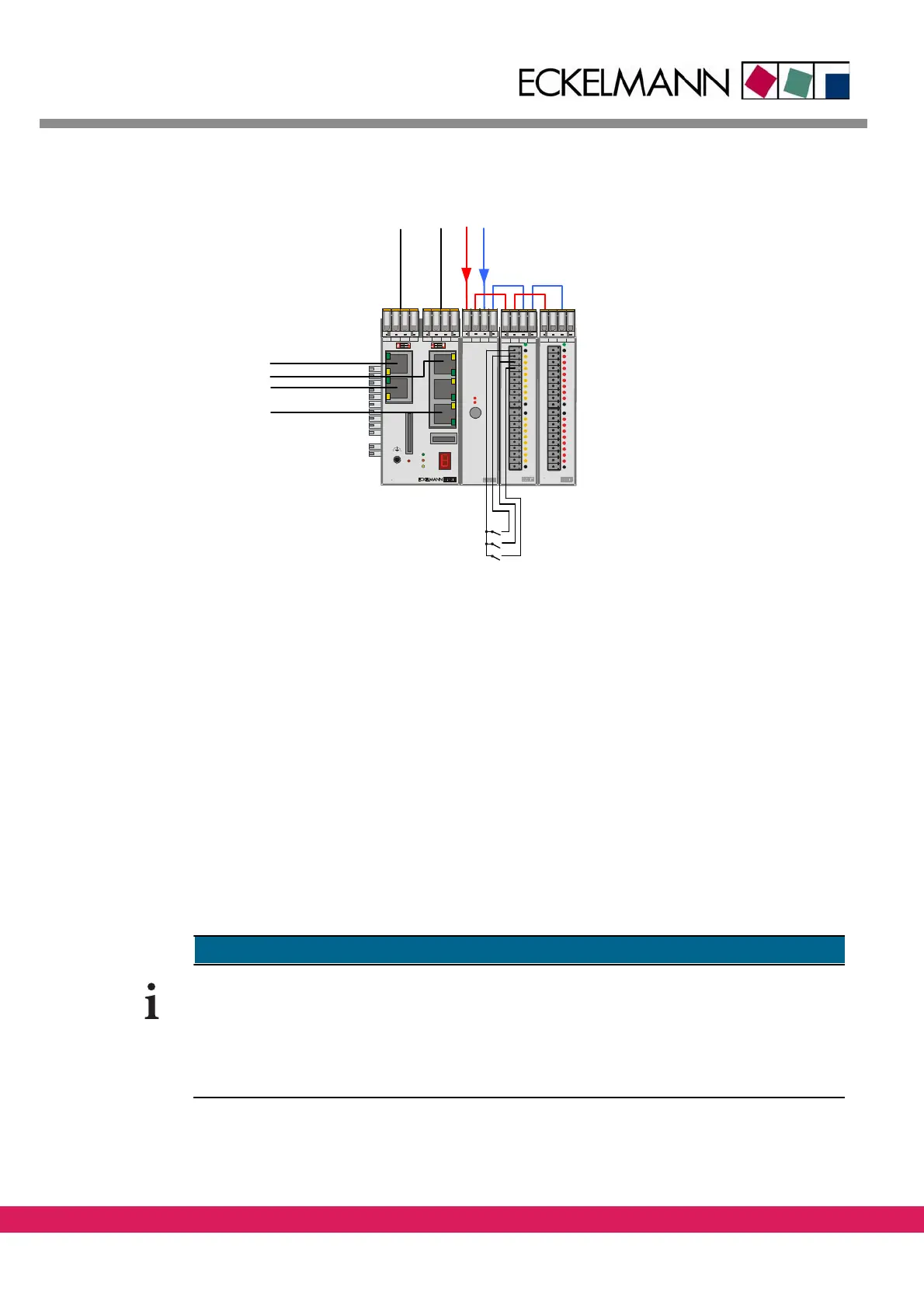

Abbildung 44:

EExC66

WDOG

LED2

LED1

USB Ethernet RS232 CAN2

CAN3CAN4SD-Card

1

2

4

3

CAN

Term

SD

WD 2 WD 1 C_GD C_H C_ L PE

E-Control ExC66 with power supply and LBM IO modules

5V

24V

5A

24V 24V 0V 0V

ELBM

PWR04

24V 24V 0V 0V

ELBM

DIM 16

I 5

I 4

I 3

I 2

I 1

24V

LIFE

I 6

I 7

I 8

0V

I 13

I 12

I 11

I 10

I 9

24V

I 14

I 15

I 16

0V

24 V 0 V

CAN1

Watchdog

CAN3

CAN4

CAN2

Ethernet

24V 24V 0V 0V

ELBM

DOM 16

O 5

O 4

O 3

O 2

O 1

24V

LIFE

O 6

O 7

O 8

0V

O 13

O 12

O 11

O 10

O 9

24V

O 14

O 15

O 16

0V

Tool down (I_ToolDown)

Tool up (I_ToolUp)

Emergency stop (I_NoEStop)

Figure 44: Controller setup for the example

• The 24V voltage is connected with the modules LBM PWR04, LBM DOM16 and LBM

DIM16

• A signal „Tool down“ (I_ToolDown) of the tool is connected with the input I1 of the

LBM DIM

16

• A signal „Tool up“ (I_ToolUp) of the tool is conn

ected with the input I2 of the LBM

DIM16

• A signal „Emergency stop circuit“ (I_NoEStop) of the drives is connected with the

input

I3 of the LBM DIM16

• A switch „Lower Tool” (O_ToolDown) is connected with the output O1 of the LBM

DOM16

9.4 Configuration of a controller in ETOOLS PLC/2

The following chapter describes the general procedure of the configuration of the control-

ler as prerequisite for the generation of a prog

ram under ETOOLS PLC2 (For further details

please check /1/).

This chapter can be skipped if the sample program CNC_Test is used, because the described

settings of an ENC66 are already available there.

Loading...

Loading...