119548

70165

119549

70166

70167

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

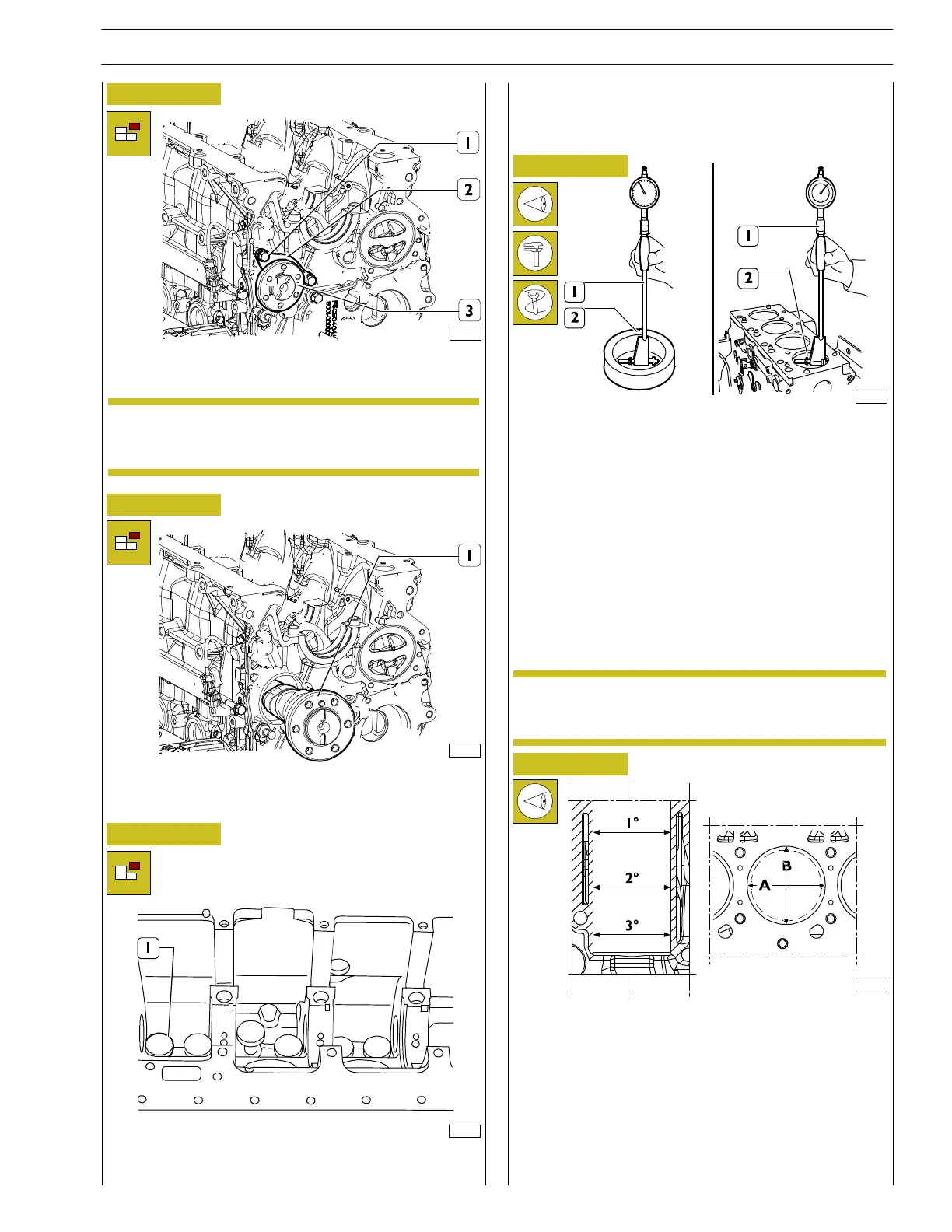

Loosen th e fastening screws (1) an d disassemble the

camshaft (3) holding plate (2).

Carefully withdraw the camshaft (1) from the engine bock.

Withdraw the tappets (1) from the engine bock.

Once completed the engine disassembly, carefully clean the

cylin der-crankcase units.

Use suitable eyebolts to handle the cylinder unit. Carefully

check the crankcase has for cracks. Check the conditions of

the processing caps: replace them if oxidized or in case their

tight is doubtful. Check the surface of the cylinder barrels:

there must be no trace of meshing, sc ratches, oval or co n ical

shaping and excessive wear.

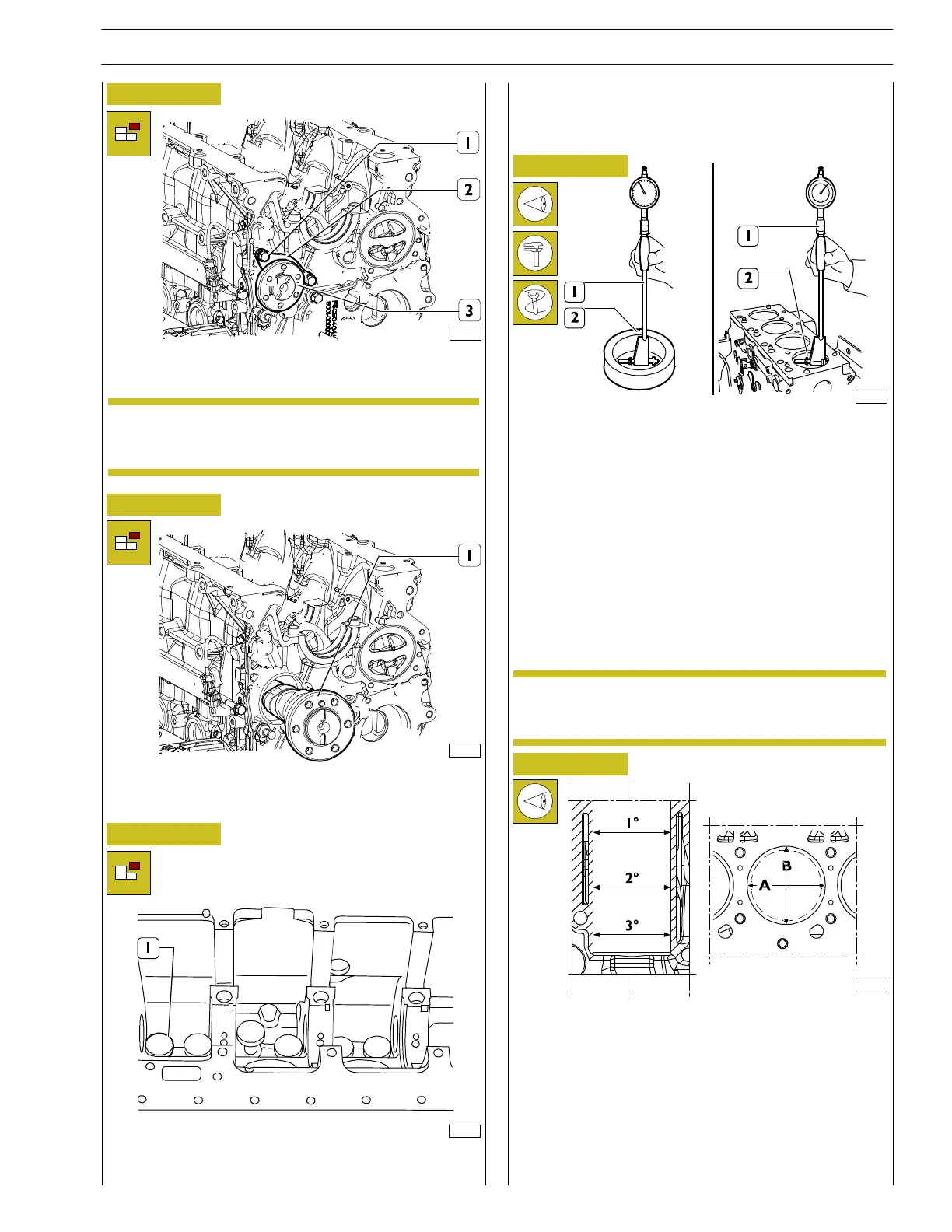

Cylinder barrel inner diameter check to detect any oval or

conical shaping or wear shall be executed throughout the

bore meter (1) equipped with comparator, which must be

previously be reset on the ring calliper (2) of th e cy linder

barrel diameter.

Themeasurementsmustbemadeforeachcylinder,atthree

different heights from the barrel and on two perpendicular

planes: one parallel to the engine longitudinal axle (A) and the

other perpendicularly (B). Generally, maximum wear is

detected on the perpendicular plane (B) and with the first

measurement.

If oval or conical shaping or wear is detected, proceed boring

and grinding the cylinder barrels. Cylinder barrel grinding

must be executed based on the spare pistons’ diameter plus

0,4 mm of the rated value and at the prescribed assembly

slack.

Note down the plate assembly position (2).

REPAIRS

CYLINDER UNIT

Checks and measurements

If the ring calliper is unavailable, use a micrometer

for reset.

s

NOTE

NOTE

SECTION 4 - MECHANICAL OVERHAUL

11

F32 SERIES

Pri nt P2D32F005 E Base - April 2009

Loading...

Loading...