119545

70158

119546

119547

120173

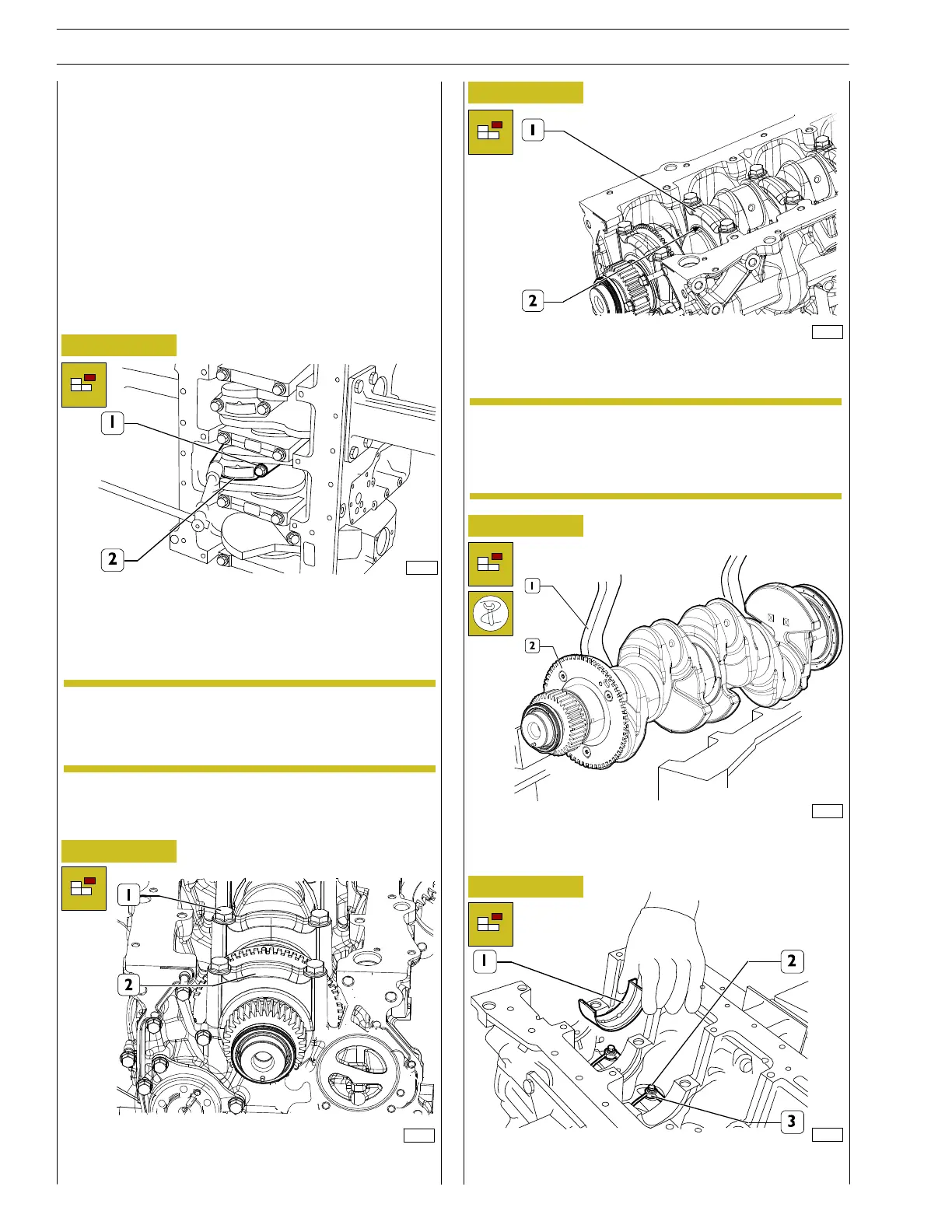

Figure 1

Figure 2

Figure 3

Figure 4

To execute the operations described here following, it is

necessary to fit the engine on the rotary stand after having

removed all the appliance’s specific components (see Section

3 of the herein manual).

This section illustrates all the more important procedures of

engine bock overhaul.

Loosen the screws(1) fastening the connecting rod caps (2)

and remove the fastening the connecting rod caps.

Withdraw the pistons with the connecting rods from the

upper part of the crankcase.

Loosen the screws (1) and disassemble the crankshaft bearing

caps (2).

The third (central) main bearing cap (1) and associated

support have a bearing-half (2) equipped with thrust.

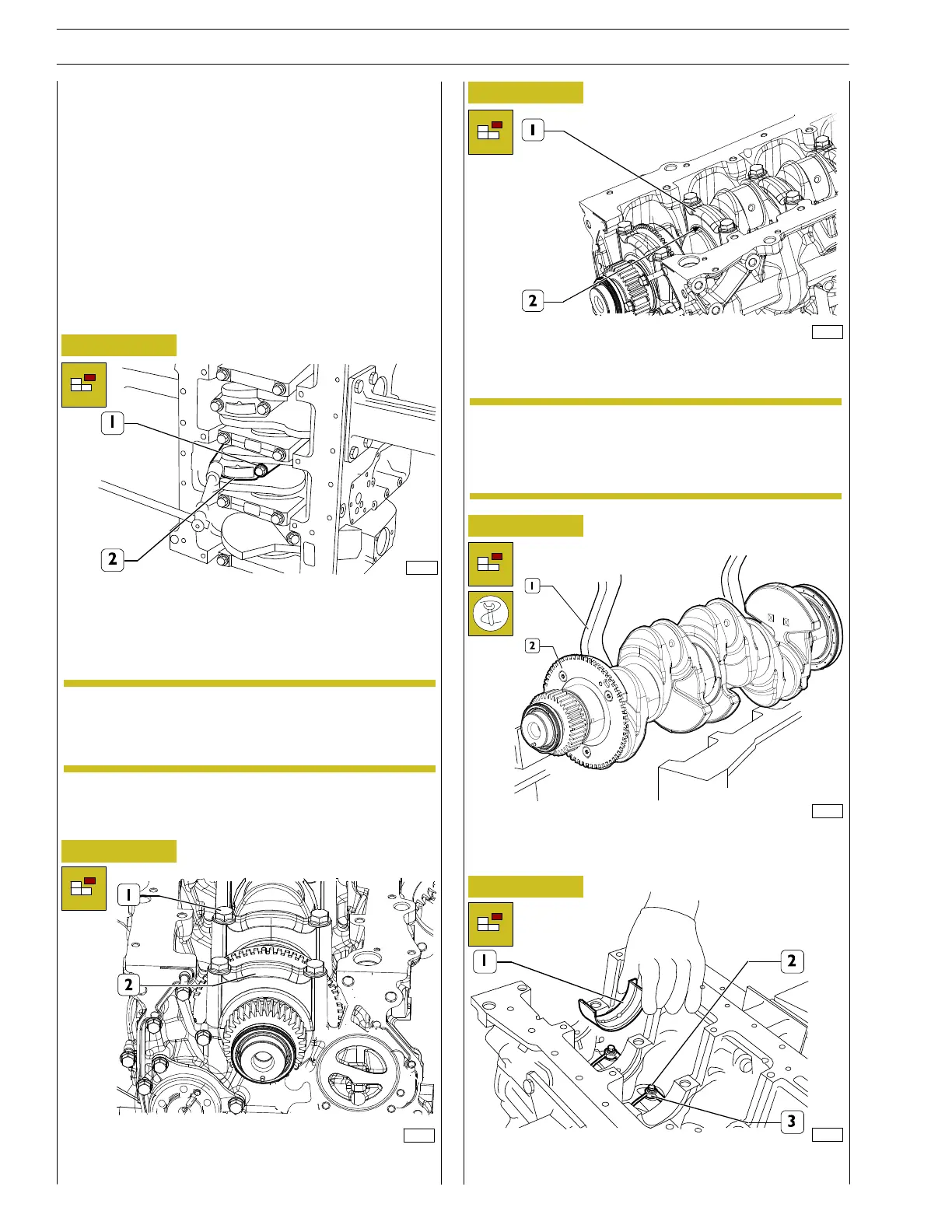

Using tool 99360500 (1) and a hoister, remove the engine

drive shaft (2) from the crankcase.

Disassemble the crankshaft half bearings (1).

Loosen the fastening screws (2) and disassemble the oil

nozzles (3).

Keep the half bearings in their respective housings

since, in case of reuse after the overhaul, they will

have to be reassembled in the same position.

Note down the assembly position of the upper and

lower half bearings since, in case of reuse after the

overhaul, they will have to be reassembled in the

same position.

Figure 5

ENGINE OVERHAUL

ENGINE DISASSEMBLY ON BENCH

NOTE

NOTE

10

SECTION 4 - MECHANICAL OVERHAUL

F32 SERIES

Base - April 2009 Print P2D32F005 E

Loading...

Loading...