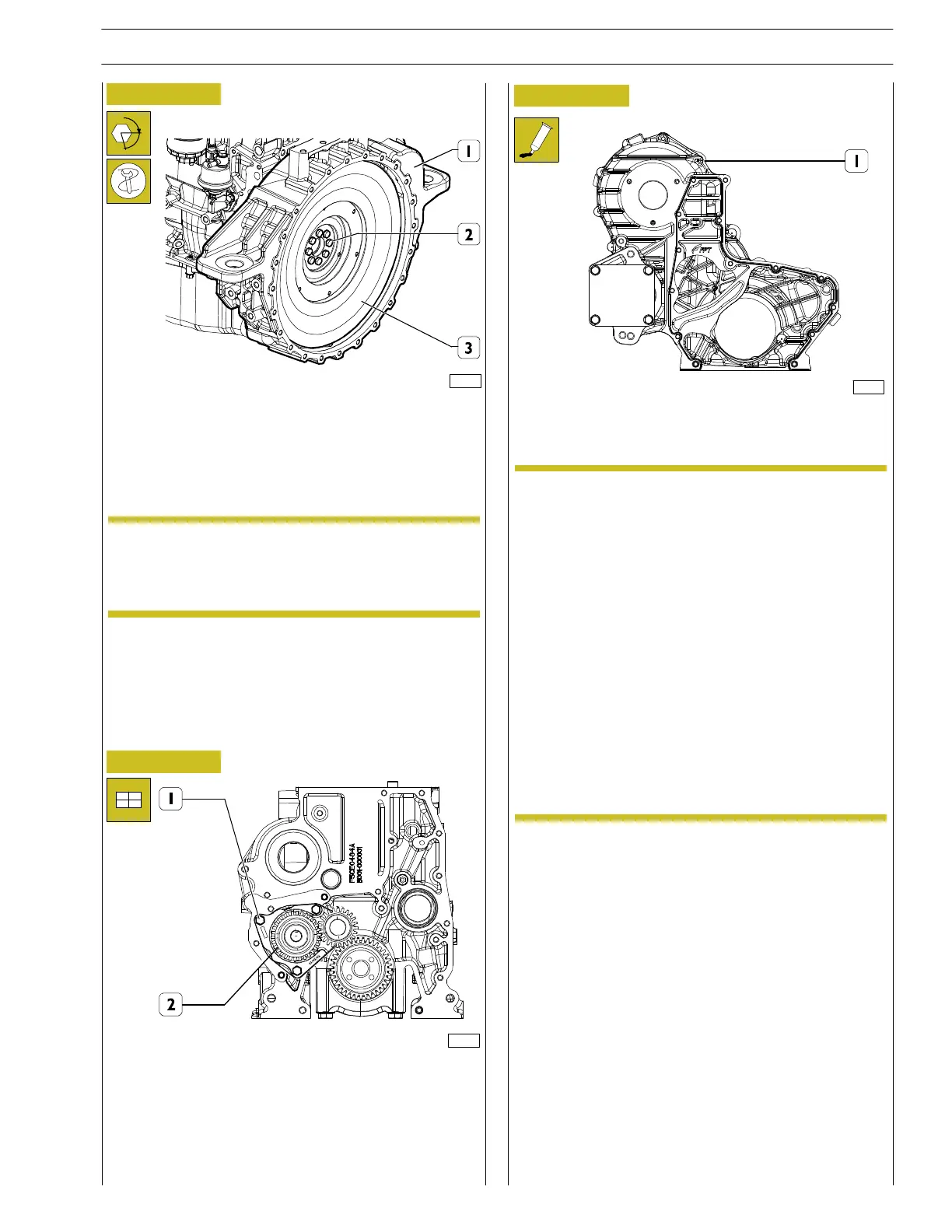

Figure 29

α

Tighten the engine flywheel (2) fastening screws (1) in two

steps:

- Step 1: 30 1.5 Nm torque setting ;

- Step 2: 90º angular fasten ing.

119463

Angular fastening must be executed using tool

99395216.

Before assembly, always ch eck that the port

threads and the screws show no trace of wear and

dirt.

NOTE

119117

- Assemble the oil pump (2).

- Tighten the fastening screws (1) to the prescribed

torque wrench.

Figure 30

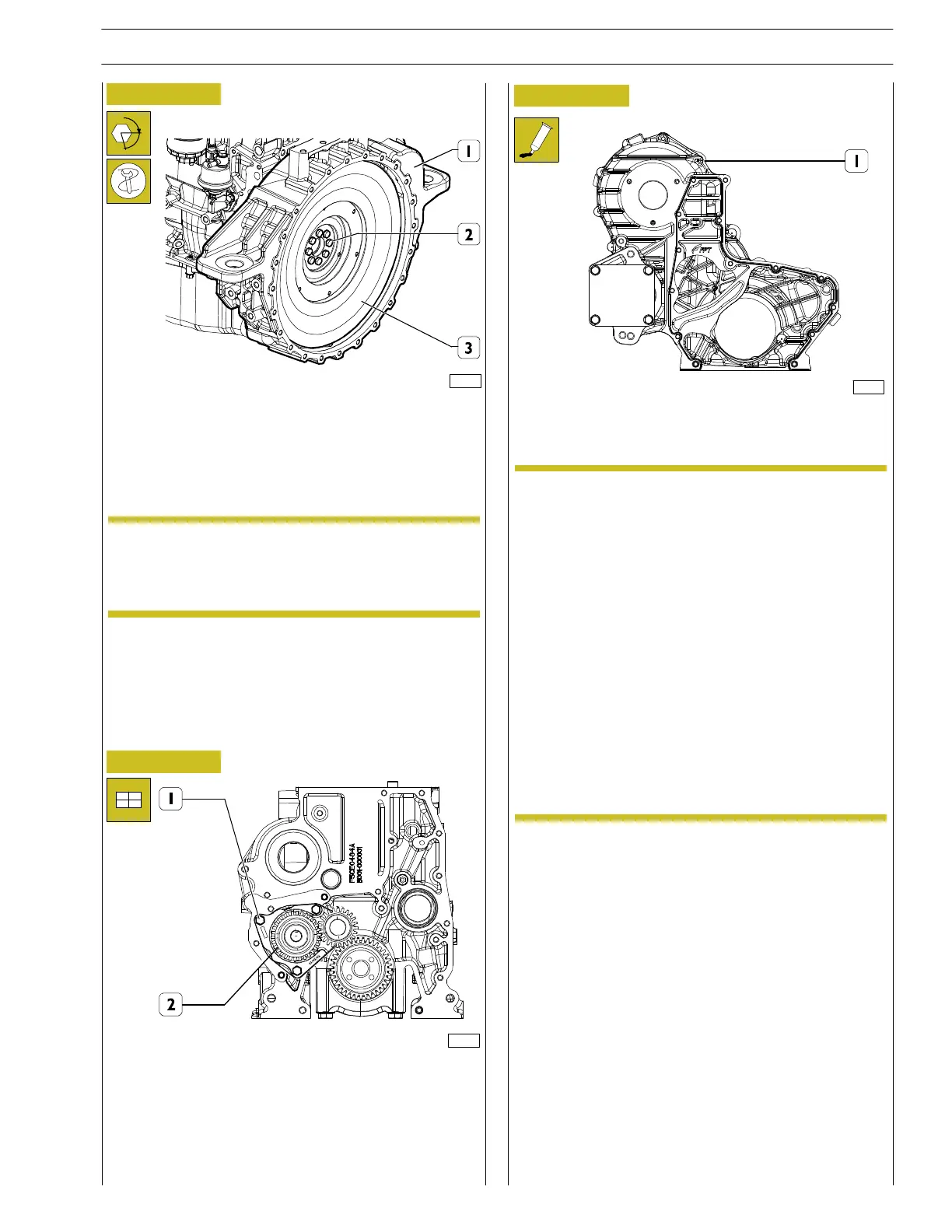

Front side component installation

SCHEME FOR THE APPLIANCE OF LOCTITE 5999

SEALER

It is absolutely necessary to clean the surface to be

sealed in order to obtain perfect tightness.

Apply LOCTITE 5999 sealer on t he gearcase in

order to form a sealing bead of a few mm.

The sealing bead must be homogeneous (no

lumps), free of air bubbles, thinner areas and gaps.

Any imperfection must be corrected as soon as

possible.

Avoid the excess of sealer: too much sealing

material would leak and pour out on both sides of

the joint parts and, as a consequence, obstruct the

passage of the lubricant.

After having applied the sealer, the parts must be

joined within 10 minutes.

Figure 31

NOTE

- Assemble the front case (1) and tighten th e fastening

screws to the prescribed torque wrench.

119733

SECTION 3 - INDUSTRIAL APPLICATION

15

F32 SERIES

Pri nt P2D32F005 E Base - April 2009

Revi - 12.2012

Loading...

Loading...