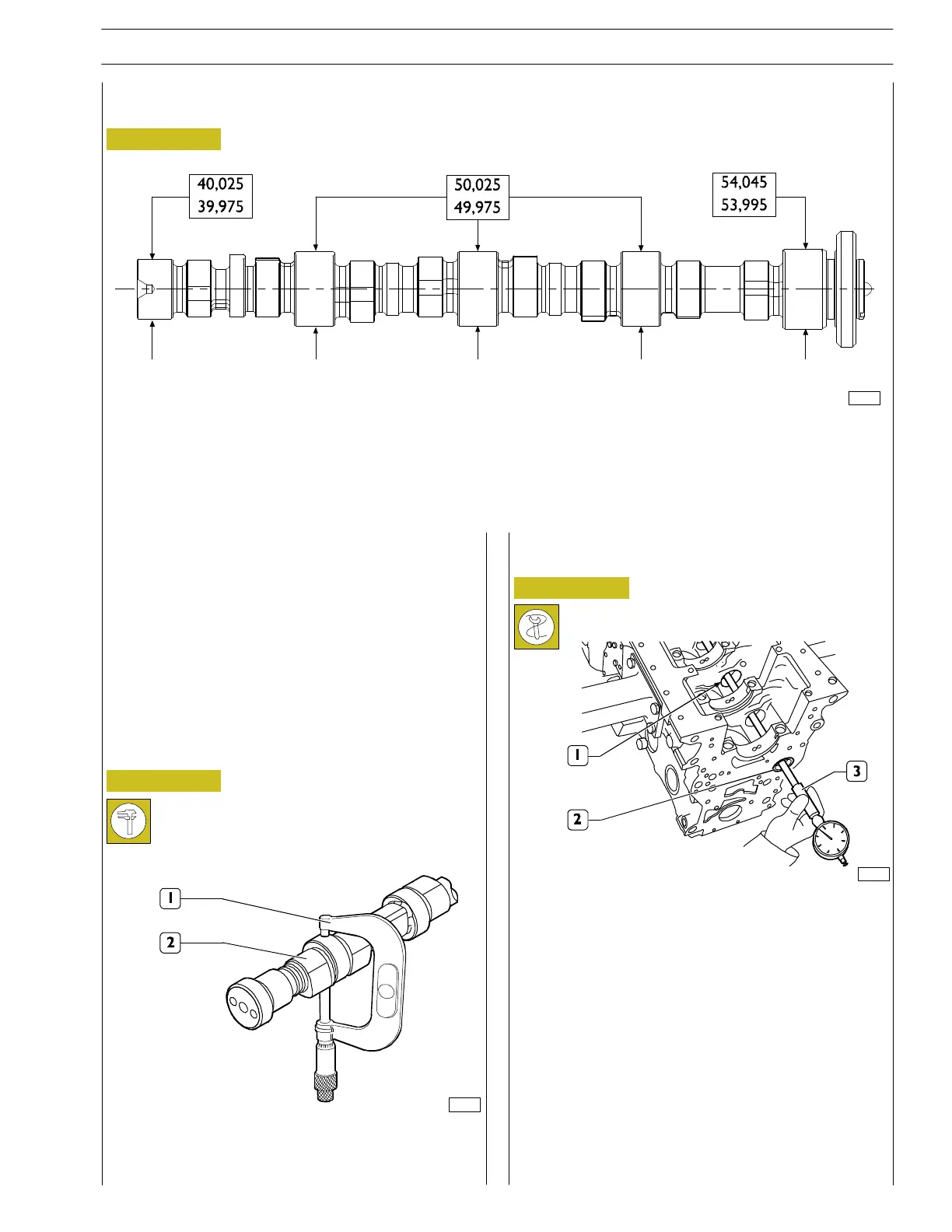

Figure 12

TIMING SYSTEM

Camshaft

119551

MAIN DATA ABOUT CAMSHAFT PINS

Thesurfaceofthecamshaftpinsandofcamsmustbe

extremely smooth. In case any trace of meshing or scratches

are detected, replace the shaft and the relevant bushes.

70171

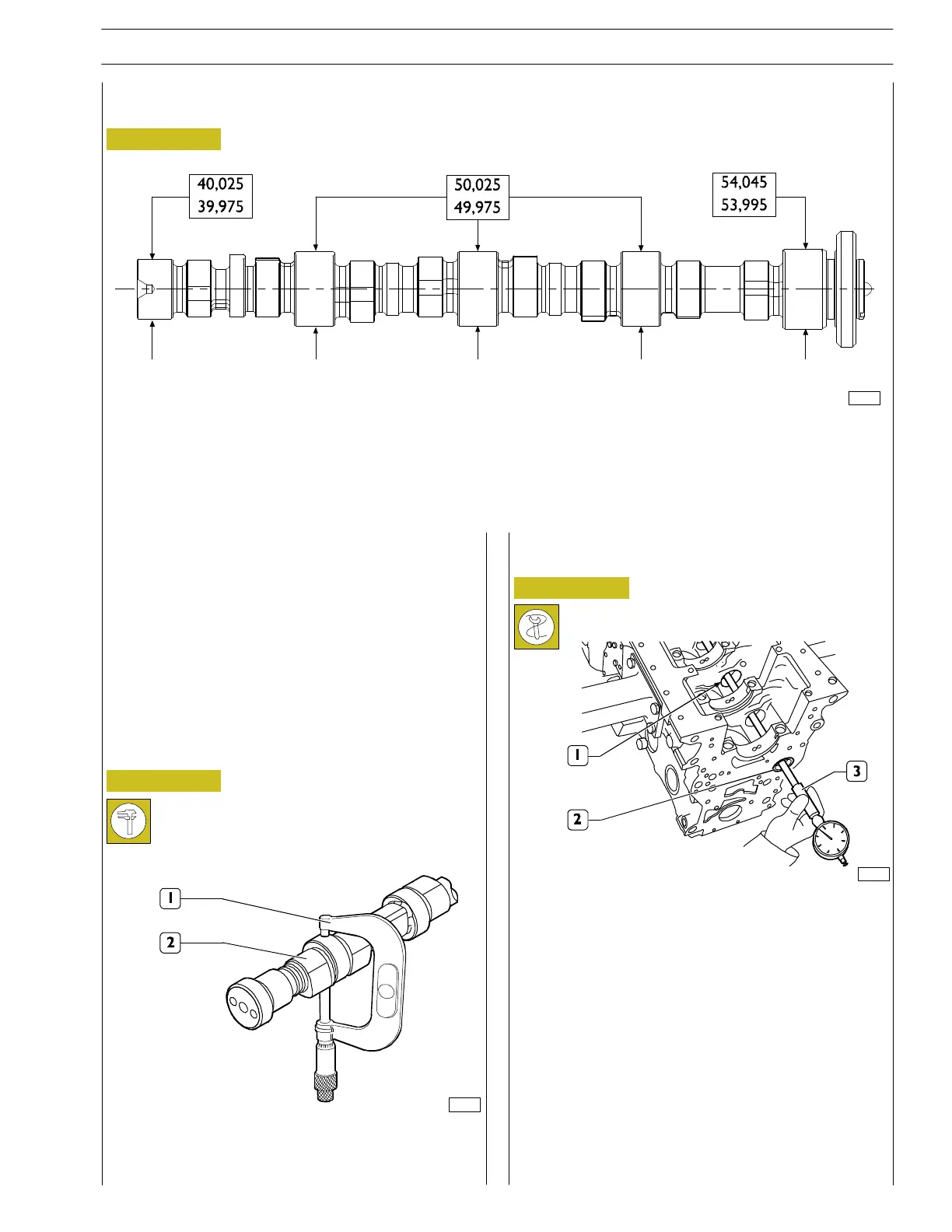

Figure 13

Using a micrometer (1), check the diameter of the camshaft

(2) supporting pins on th e two perpendicular axles.

Checking cam lift and pin alignment

Place the camshaft on footstocks and, throughout a

centesimal comparator placed on the central support, check

that the radial oscillation does not exceed 0.015 mm

otherwise replace the shaft.

70172

Figure 14

The front camshaft bush (2) must be thrust in the respective

seat.

There must be no trace of meshing or wear in the inner

surface.

Using a bore meter (3) measure the front adiameter of the

camshaft bush (2).

Measurements must be made on two perpendicular axles.

BUSH

SECTION 4 - MECHANICAL OVERHAUL

13

F32 SERIES

Pri nt P2D32F005 E Base - April 2009

Loading...

Loading...