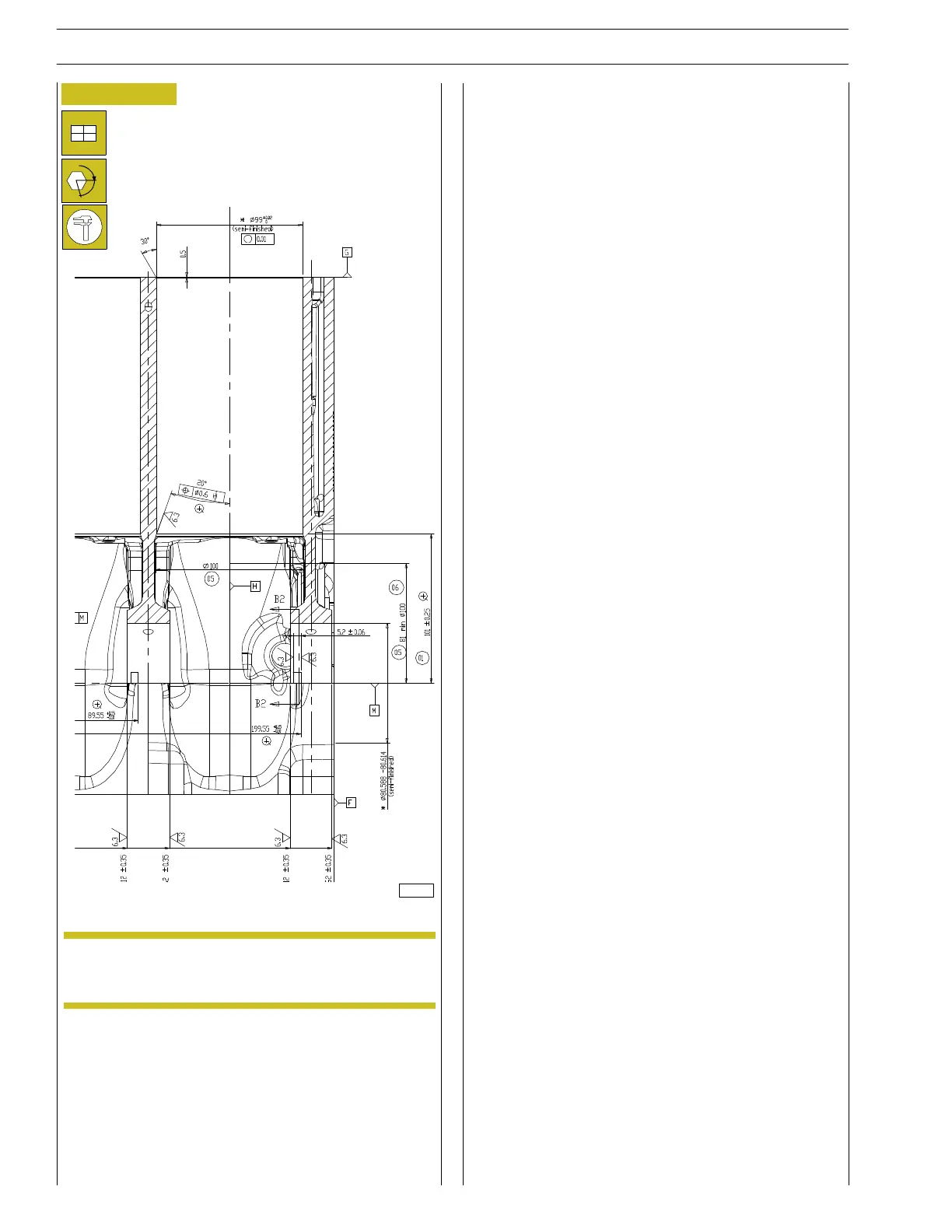

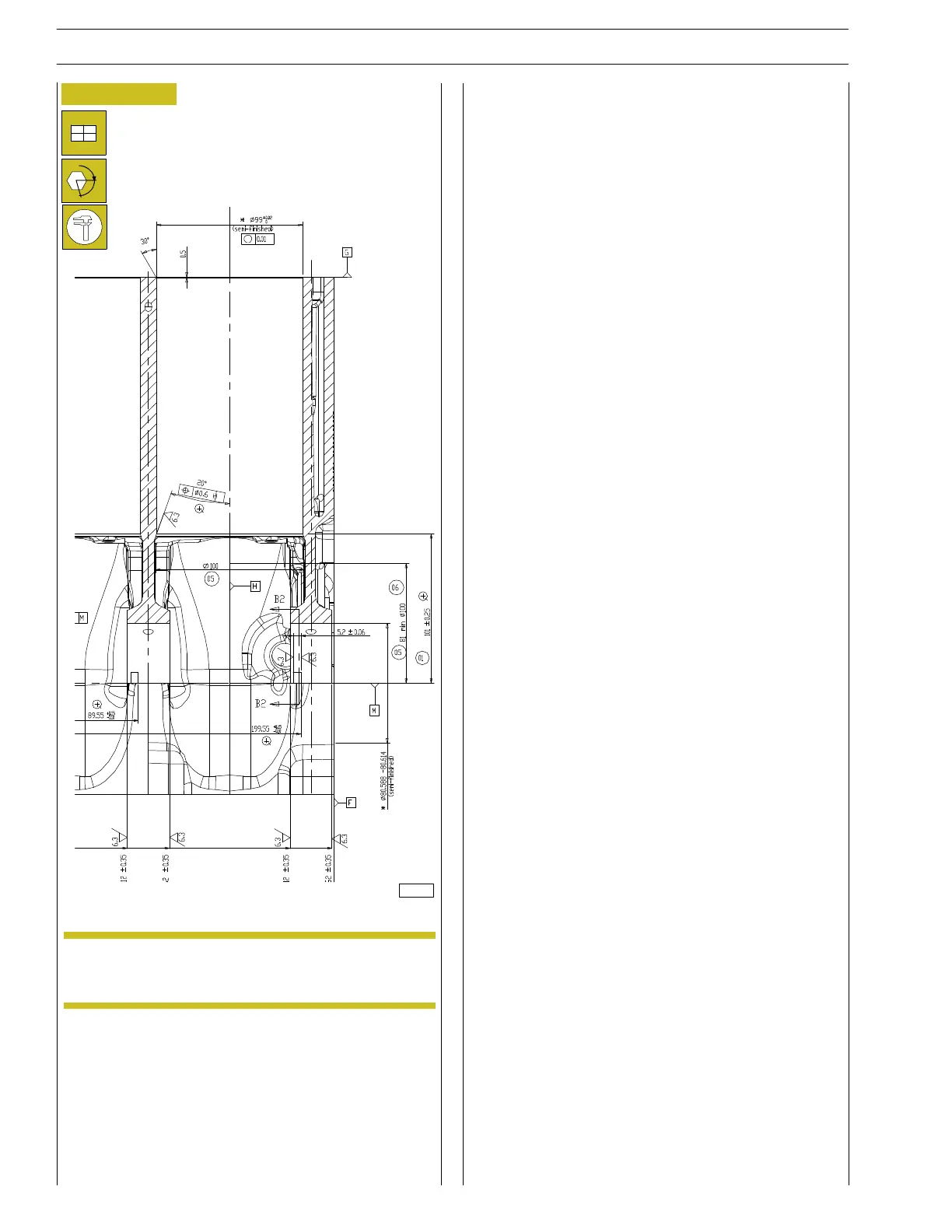

Figure 11

Checking head base surface on cylinder unit

After having detected any deformed areas, grind the head

base surface using a grinding machine.

Planarity error must not exceed 0.075 mm. Check the

conditions of the cylinder unit processing caps: replace them

if oxidized or in case th eir tight is doubtful.

α

Check the crankshaft bearing seats proceeding as follows:

- fit the crankshaft bearing caps on the supports without

bearings;

- tighten the fastening screws to the prescribed torque

setting;

- with a suitable comparator, check that the inner barrel

diameter corresponds to the prescribed value.

If the detected value is higher, replace the crankcase.

Il terzo (quello centrale) cappello di banco (1) e il relativo

supporto hanno il semicuscinetto (2) dotato di spallamento.

119550

In case of grinding, all the barrels must result having

the s ame oversize (0.4 mm).

NOTE

12

SECTION 4 - MECHANICAL OVERHAUL

F32 SERIES

Base - April 2009 Pri nt P2D32F005 E

Loading...

Loading...