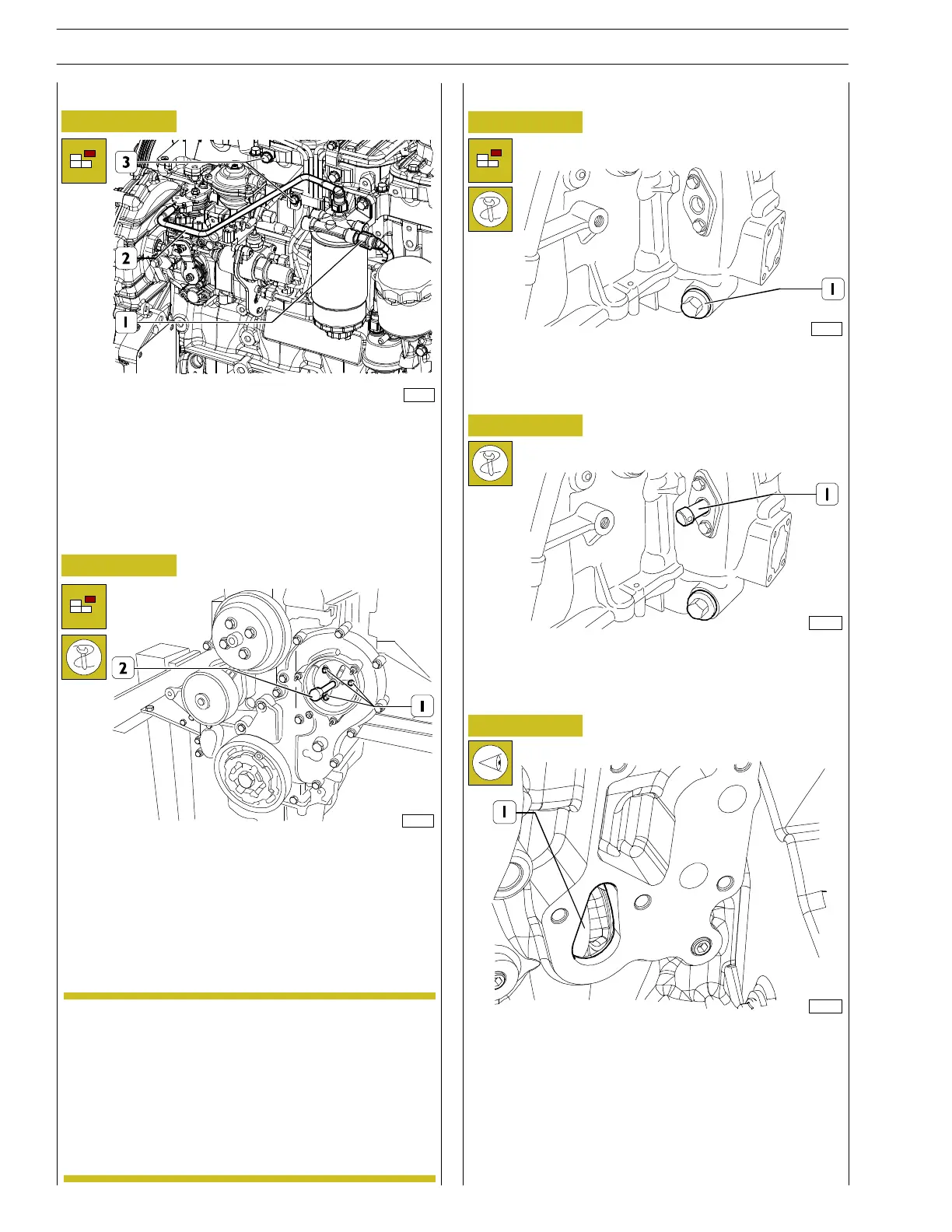

119720

Figure 4

- Remove the L.D.A. pipe. Remove the fast clutch fuel

pipes from the priming pump to the filter (1) and from

the filter to the ignition pump (2), then fit the specially

provided caps to the pipes, the pumps and the filter.

Unscrew the screws (3), fastening the fuel ignition pipes

and remove them.

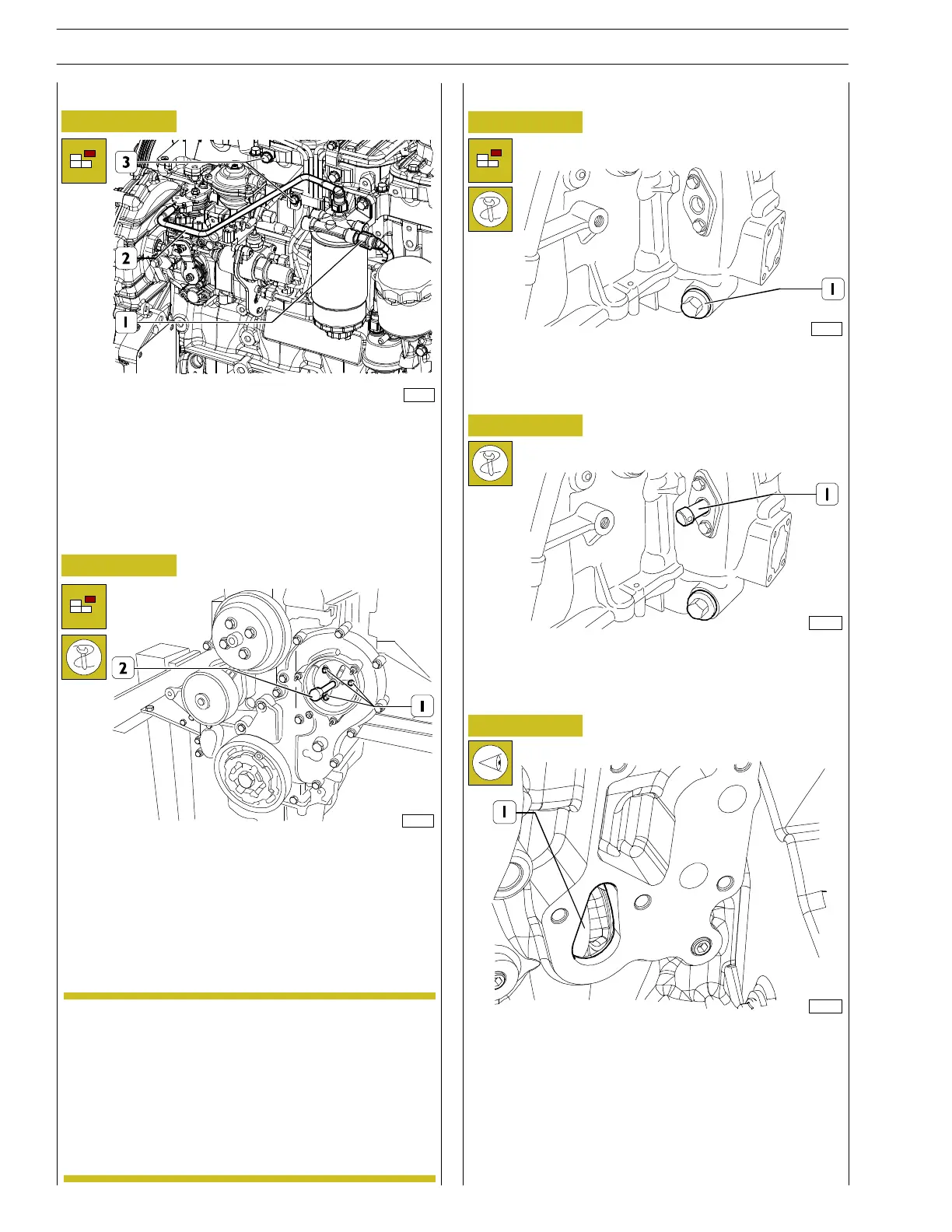

119106

Figure 5

- Unscrew the pump fastening screws on the rear part of

the gear cover. To disassemble the pump, fit tool

99340025 to th e pump wheel and fix it with the three

screws (1).

Using the specially provided wrench, slowly tighten the

screw (2) holding th e rear part of the pump removing

the pump completely.

Before pump disassembly, use the

speciallyprovided tool (99360612), lock the engine

into theposition corresponding to T.D.C. for

cylinder 1. Now block with the specific system the

pump shaft; this way the pump should be timed, so

that when refitting (if no maintenance intervention

is required on it) no adjustment is necessary.

NOTE

For all engines

Figure 6

Cylinder 1 T.D.C. search

Position the engine drive shaft at T.D.C. of cylinder 1 rotating

the flywheel un t il achieving t h e following c on ditions:

- the notch (1) is visible from the in spection hole;

- to ol 99360612 should be fitted through the carter into

the port on the flywheel.

Remove tools and tighten the previously loosened plate

screws.

124497

Figure 7

- Fit tool (1) 99360330 to flywh eel housing to rotate the

flywheel (must be used with a suitable wrench).

Figure 8

- Loosen the screws of the plate in which tool 99360612

(1) is to be fitted.

132006

133189

8

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Base - April 2009 Prin t P2D 32F005 E

zl

Loading...

Loading...