2.7 Installation of high rigidity radial cylinder type

2-52

2. Installation

2.7 Installation of high rigidity radial cylinder type

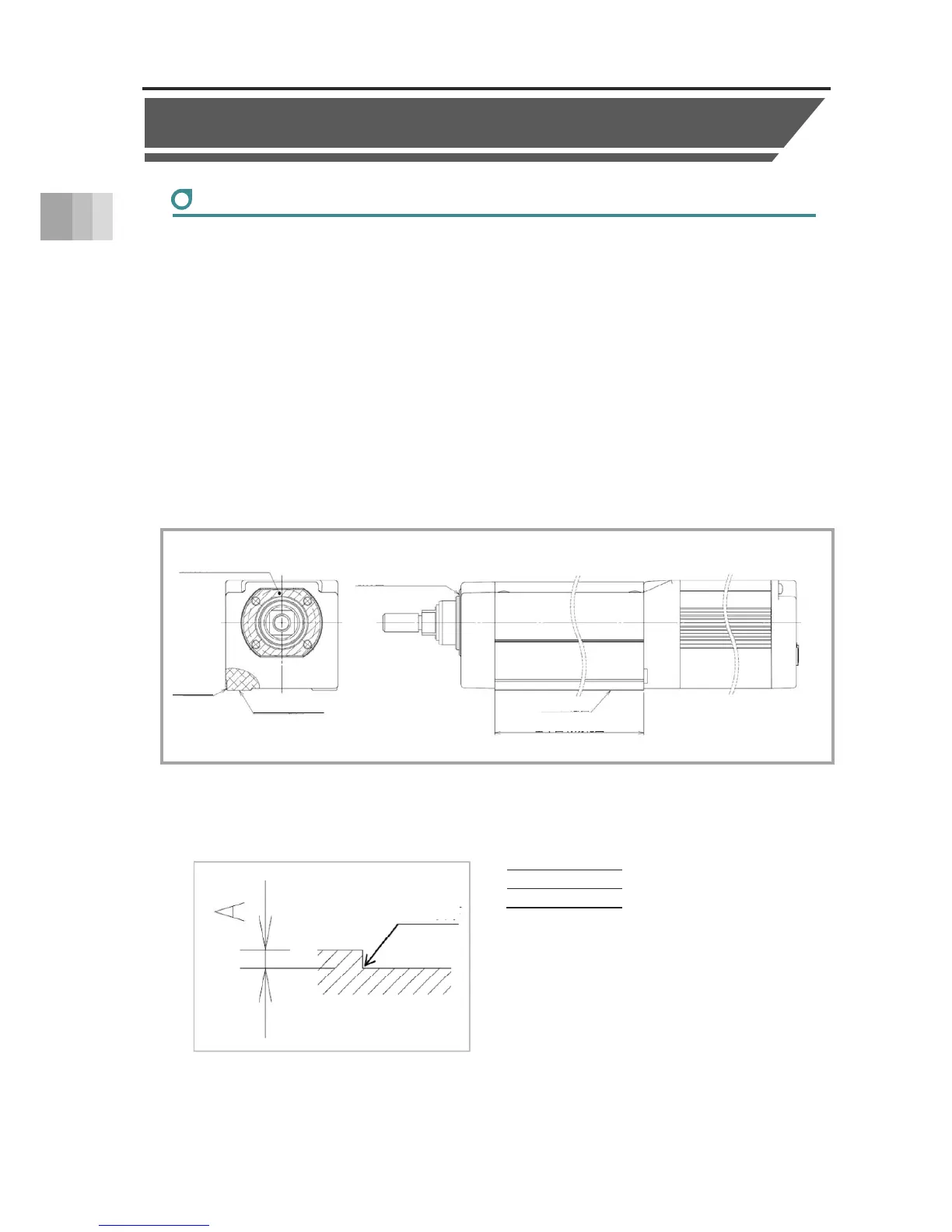

Installation surface

● The body installation surface should be a machined surface or a plane with similar accuracy,

with flatness within 0.05mm/m.

● The mounting frame should have a structure rigid enough to prevent the generation of

vibration.

● Also consider the necessary space for maintenance work such as ELECYLINDER

replacement and inspection.

● The bottom surface and left side surface (viewed from motor opposite side) of the body base

serve as the reference surfaces for rod running. Use these surfaces as the reference

surfaces for mounting when running accuracy is required.

● When applying radial load/moment load, fix the entire surface of the base bottom.

Flange fixing may cause deflection or reflexion throughout the product due to radial

load/moment load, leading to vibration, shortened product life, or breakdown.

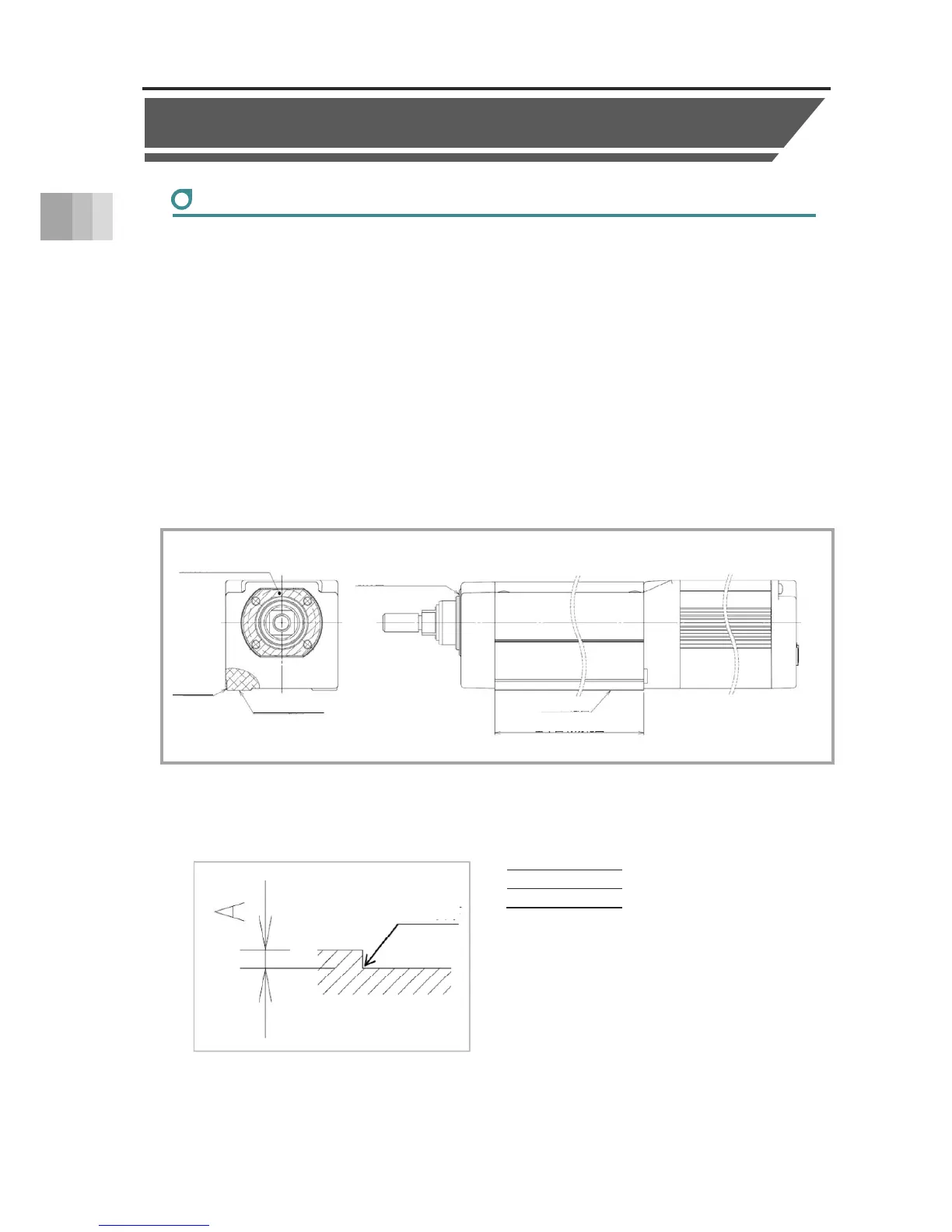

When mounting using the side reference surface, machine the installation surface according to

the figure below.

A dimension

2 to 4mm

Front bracket

mountin

Loading...

Loading...