430

INTELLIGENT ACTUATOR

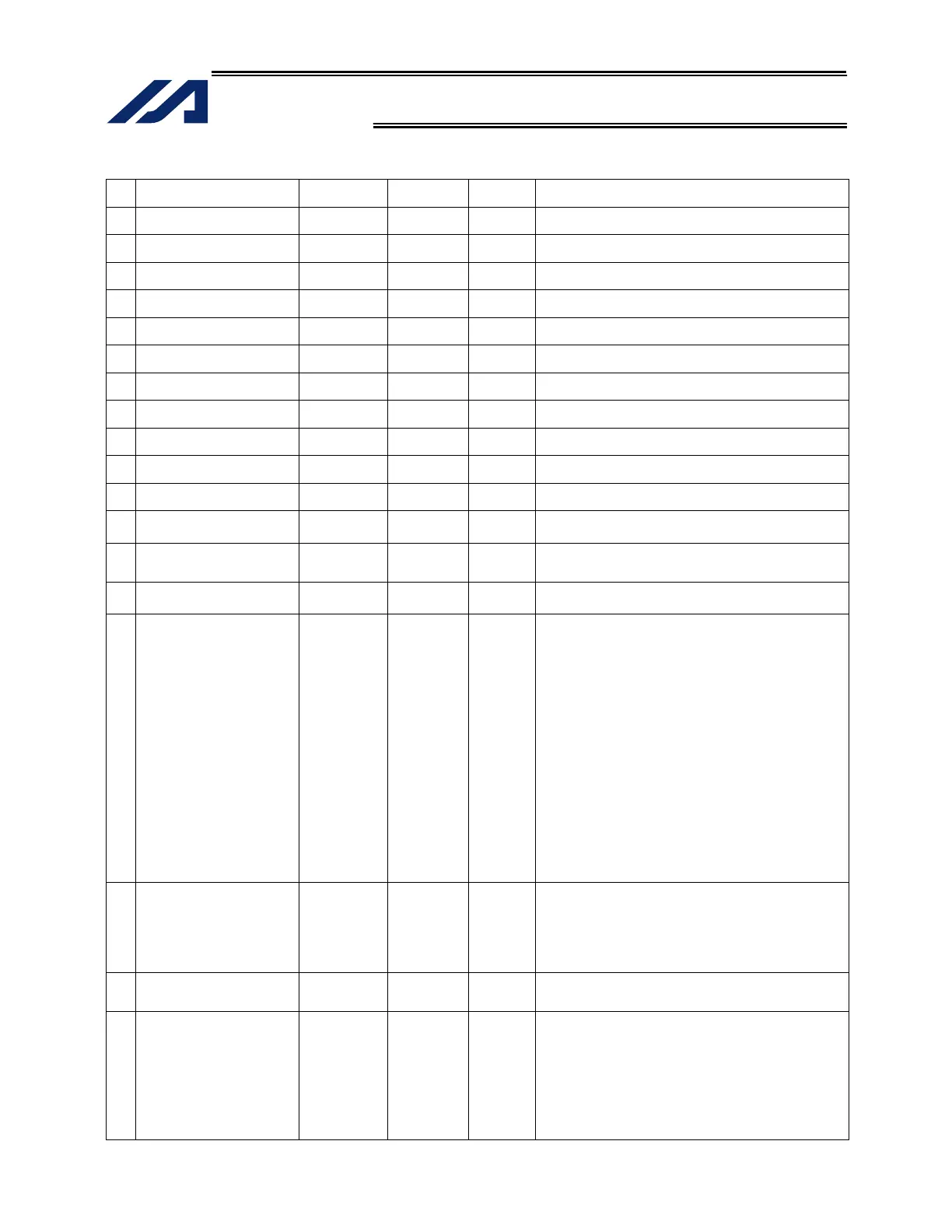

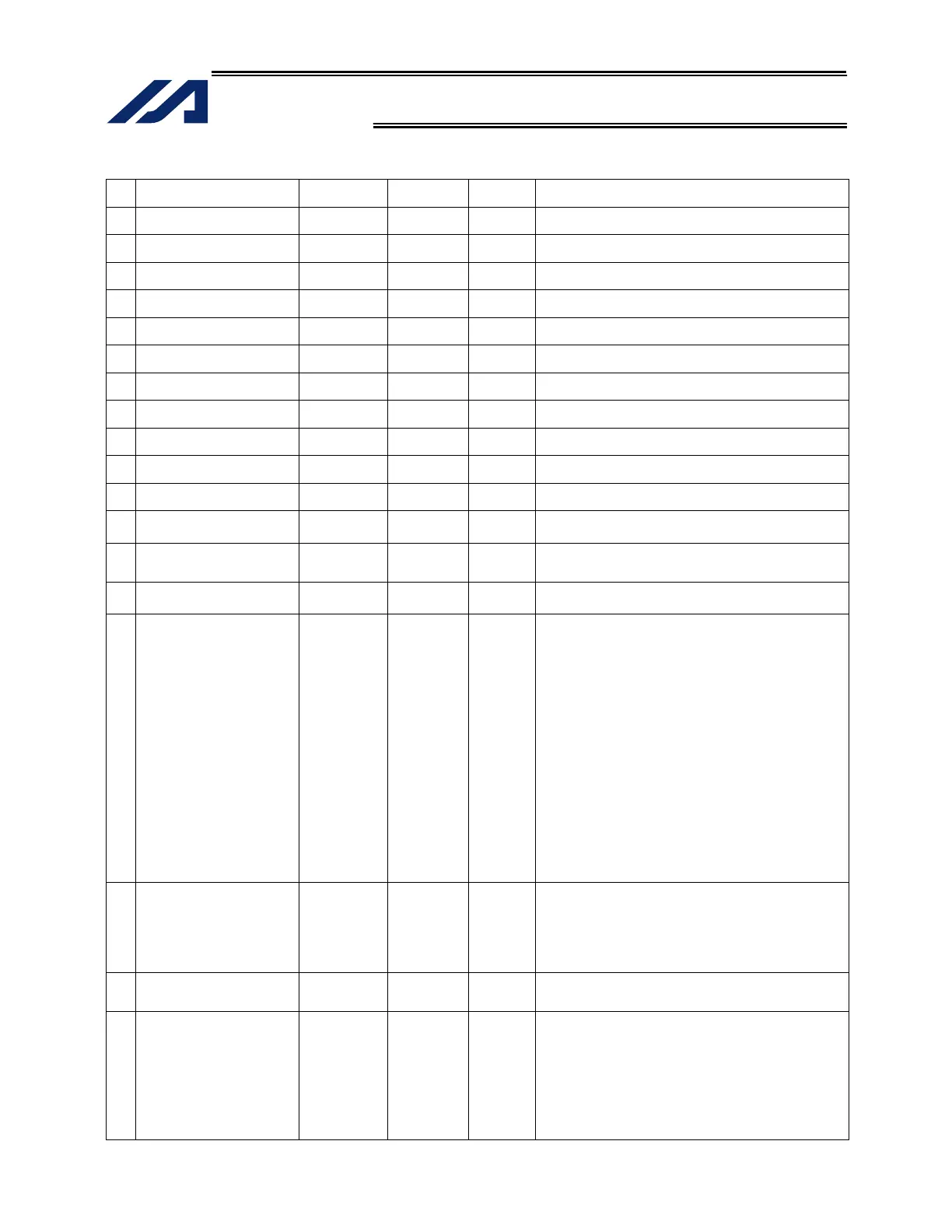

Appendix

Axis-Specific Parameters

No Parameter name

Default value

(Reference)

Input range Unit Remarks

87 Zone 1 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

88 Zone 1 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is

input; multiple specification is invalid)

89 Zone 2 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

90 Zone 2 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

91 Zone 2 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is

input; multiple specification is invalid)

92 Zone 3 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

93 Zone 3 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

94 Zone 3 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is

input; multiple specification is invalid)

95 Zone 4 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

96 Zone 4 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for

at least 3 msec.

97 Zone 4 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is

input; multiple specification is invalid)

98

to

100

(For expansion) 0 ~

101

Allowable time for exceeding

continuous-operation enable

torque

0 0 to 300 S

If 0, the allowable time for exceeding continuous-operation

enable torque is not monitored.

(Main application version 0.71 or later)

102

to

103

(For expansion) 0 ~

104 Target axis specification for

multiple-slider near-miss

detection

0H 0H to

FFFFFFFFH

Bits 0 to 3: Mating axis number of near-miss detection

target (on the positive side of the coordinate

system of the target axis)

Bits 4 to 7: Mating axis number of near-miss detection

target (on the negative side of the coordinate

system of the target axis)

* The mating axis must be entered for each

axis. (Of the pair, the axis with the smaller

axis number becomes the main axis for the

sake of convenience.)

* For each axis, only an axis whose

resolution and other related characteristics

are the same can be specified as a mating

axis.

* In the case of synchro axes, always specify

the synchro master axis. (Specification of

the synchro slave axis is prohibited.)

* Specify “0” if no adjacent slider is present

on the applicable side of the coordinate

system of the target axis.

(Main application version 0.51 or later)

105 Effective stroke of multiple

sliders

0 0 to

99999999

0.001 mm

Set the result of [Inter-slider distance at the farthest

position allowed] – [Inter-slider distance at the closest

position allowed] when both axes subject to multiple-slider

near-miss detection are inside the range of operation.

(This parameter is valid only for the master axis between

the multiple-slider axes.)

(Main application version 0.51 or later)

106

Emergency deceleration

margin upon multiple-slider

near-miss detection

5 0 to 999 0.01 G (Main application version 0.51 or later)

107 Multiple-slider setting: Bit

pattern 1

12H 0H to

FFFFFFFFH

Bits 0 to 3: Margin for multiple-slider actual position near-

miss detection (mm)

(Of the multiple sliders, only the parameter for

the master axis is valid.)

(Main application version 0.51 or later)

Bits 4 to 7: Margin for multiple-slider command position

near-miss detection (mm)

(Of the multiple sliders, only the parameter for

the master axis is valid.)

(Main application version 0.51 or later)

Loading...

Loading...