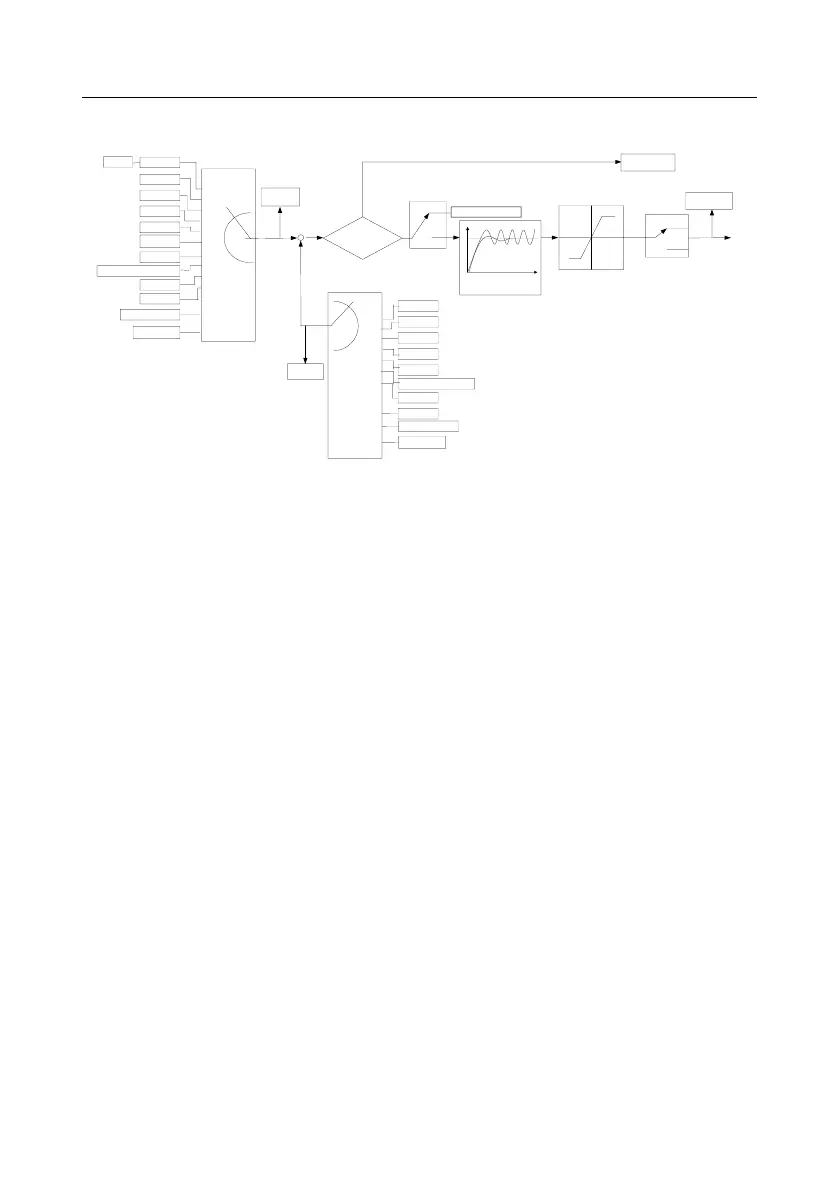

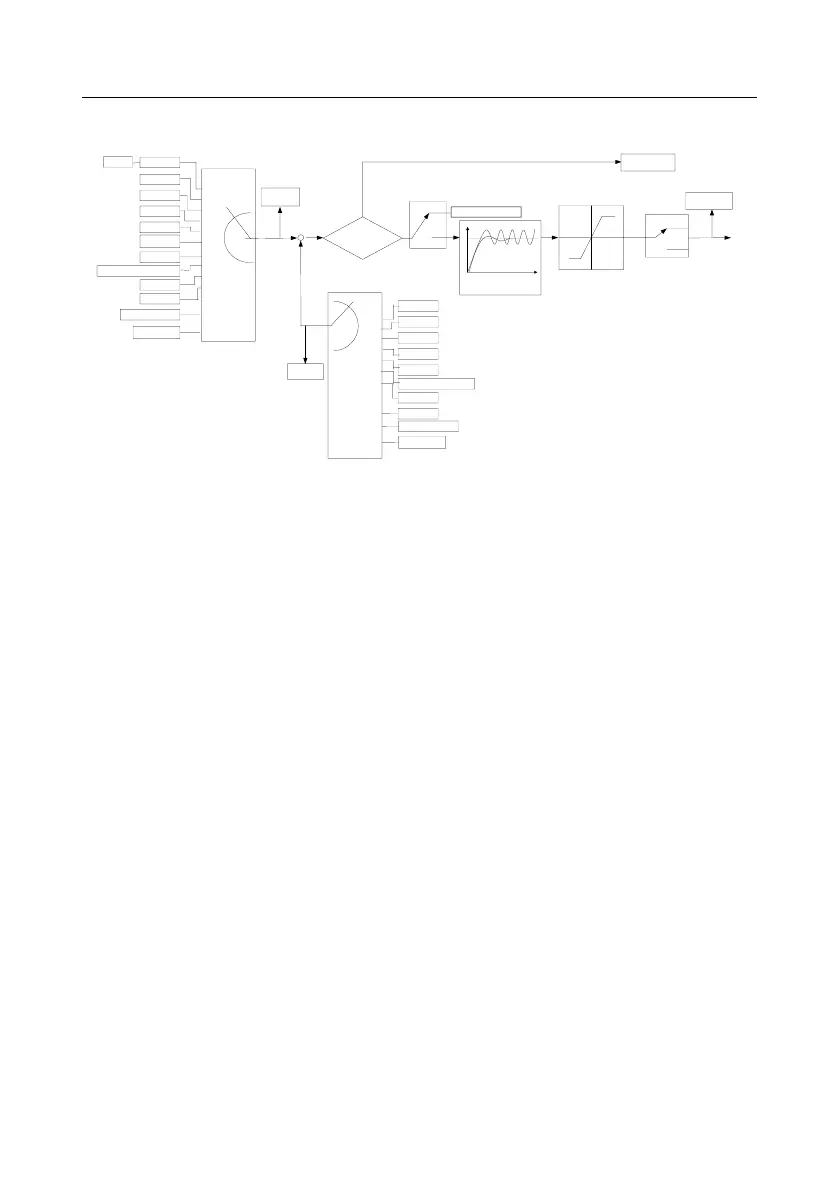

+

-

Reference-

feedback<P09.08?

P09.10

(lower limit value of PID

output)

P09.09

(upper limit value of PID

output)

0

1

P09.03

(PID output characteristics)

PID output

P17.00

P17.23

P09.08 (Limit of PID control

deviation)

P09.02

(PID feedback source)

P09.00

(PID reference source)

P17.24

PID feedback

value

PID reference

value

Set frequency

0

1

2

3

4

5

6

7

8

9

Keypad

AI1

PROFIBUS\CANopen

MODBUS

Multi-step

speed

HDIA

AI3

AI2

Ethernet

HDIB

0

1

2

3

4

5

6

7

AI1

PROFIBUS\CANopen

MODBUS

HDIA

AI3

AI2

Ethernet

Y

N

PID stops

adjustment

Pre-set PID reference of

keypad

Keep current frequency

Terminal function 25

PID control pause

Valid

Invalid

Kp P09.04 (proportional gain)

Ti P09.05 (integral time)

Td P09.06 (differential time)

P09.01

EtherCat/Profinet

PLC card

10

11

HDIB

EtherCat/Profinet

PLC card

8

9

10

Introduction to the working principles and control methods for PID control

Proportional control (Kp): When the feedback is different from the reference, the output will be

proportional to the difference. If such a difference is constant, the regulating variable will also be

constant. Proportional control can respond to feedback changes rapidly, however, it cannot eliminate

the difference by itself. A larger proportional gain indicates a faster regulating speed, but a too large

gain will result in oscillation. To solve this problem, set the integral time to a large value and the

differential time to 0, run the system only with proportional control, and then change the reference to

observe the difference (that is, static difference) between the feedback signal and reference. If the

static difference occurs in the direction of reference change (such as reference increase, where the

feedback is always less than the reference after system stabilizes), continue increasing the

proportional gain; otherwise, decrease the proportional gain. Repeat this process until the static

difference becomes small.

Integral time (Ti): When feedback deviates from reference, the output regulating variable accumulates

continuously, if the deviation persists, the regulating variable will increase continuously until deviation

disappears. Integral regulator can be used to eliminate static difference; however, too large regulation

may lead to repetitive overshoot, which will cause system instability and oscillation. The feature of

oscillation caused by strong integral effect is that the feedback signal fluctuates up and down based

on the reference variable, and fluctuation range increases gradually until oscillation occurred. Integral

time parameter is generally regulated gradually from large to small until the stabilized system speed

fulfills the requirement.

Derivative time (Td): When the deviation between feedback and reference changes, output the

regulating variable which is proportional to the deviation variation rate, and this regulating variable is

only related to the direction and magnitude of the deviation variation rather than the direction and

magnitude of the deviation itself. Differential control is used to control the feedback signal variation

Loading...

Loading...