HD2 Series Inverter Product Overview

-9-

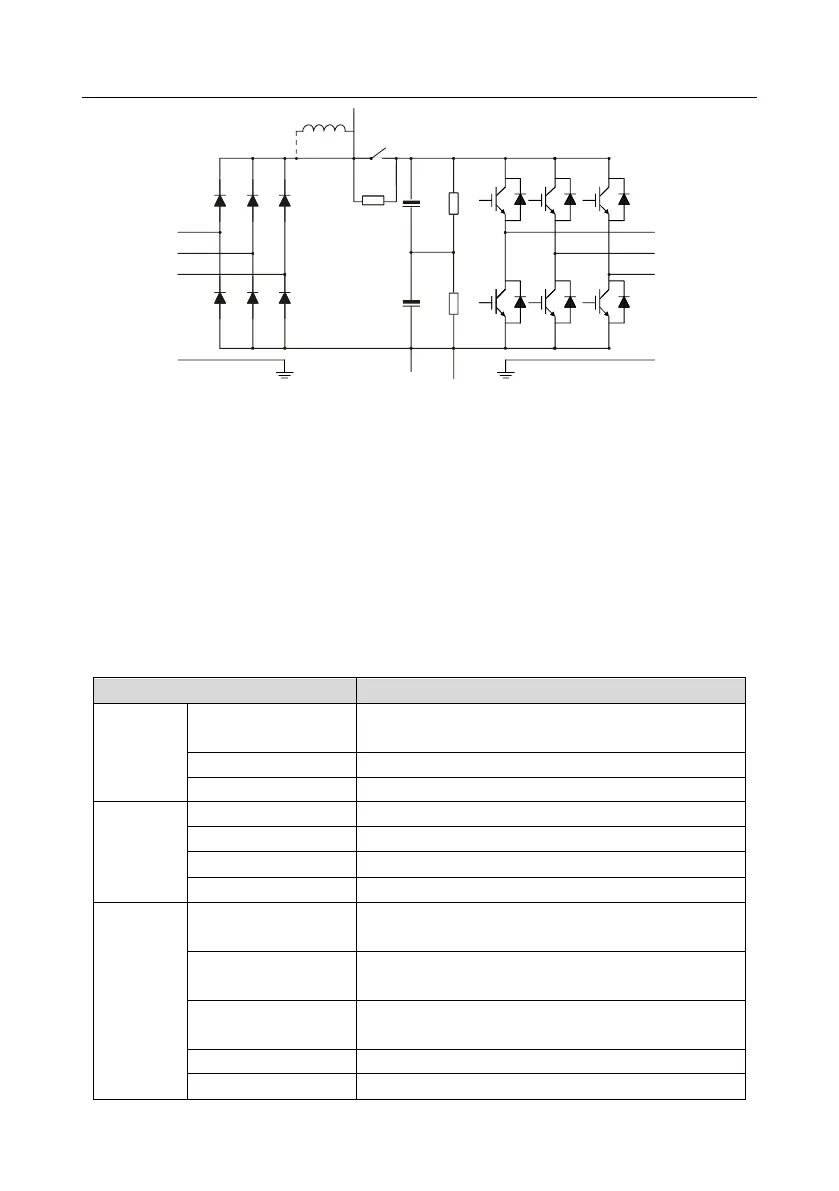

R

S

T

U

V

W

(

+)

(

-)

DC reactor

P1

PE PE

Figure 3-3 380V (132kW and higher) main circuit diagram

Note:

⚫ The 380V 132kW and higher inverter models can be connected to external DC reactors. Before

connection, remove the copper bar between P1 and (+). The 380V 132kW and higher inverter

models can be connected to external braking units. DC reactors and braking units are optional

parts.

⚫ The 380V 18.5kW–110kW (inclusive) inverter models are equipped with built-in DC reactors.

⚫ The 380V 37kW and lower inverter models carry built-in braking units, which are optional for the

45kW–110kW (inclusive) models. The models with built-in braking units can also be connected to

external braking resistors. Braking resistors are optional parts.

3.3 Product specifications

AC 3PH 380V (-15%)–440V (+10%) Rated voltage: 380V

AC 3PH 520V (-15%)–690V (+10%) Rated voltage: 660V

Refer to section 3.6 Ratings.

50Hz or 60Hz, allowable range: 47–63Hz

Refer to section 3.6 Ratings.

Refer to section 3.6 Ratings.

Technical

control

performance

Space voltage vector control, sensorless vector control

(SVC), and feedback vector control (FVC)

Asynchronous motor, permanent-magnet synchronous

motor

Asynchronous motor 1: 200 (SVC); Synchronous motor 1:

20 (SVC), 1:1000 (FVC)

±0.2% (SVC), ±0.02% (FVC)

Loading...

Loading...